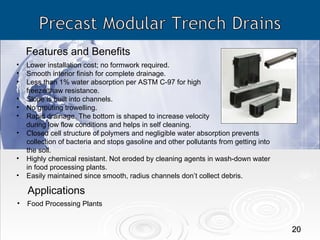

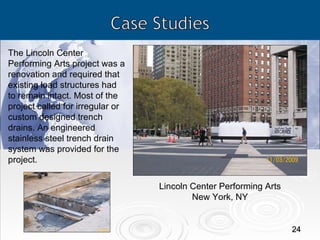

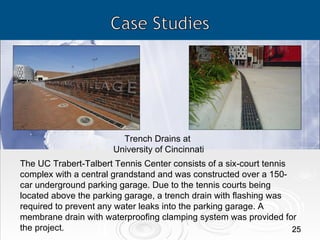

The document provides an overview of trench drainage systems, detailing their design, benefits, and applications across various industries. It outlines the advantages of modern engineered trench drains compared to traditional systems, including cost efficiency, maintenance, and installation ease. Additionally, it includes case studies to illustrate successful implementations of trench drain systems.

![Course Sponsor: Jay R. Smith Mfg. Co. 2781 Gunter Park Dr. E Montgomery, AL 36109 Ph: 334-277-8520 Fax: 334-272-7396 [email_address] www.jrsmith.com](https://image.slidesharecdn.com/trenchdrains-110819080734-phpapp02/85/Trench-Drain-Systems-Types-Benefits-Applications-and-Overview-1-320.jpg)

![Course Sponsor: Jay R. Smith Mfg. Co. 2781 Gunter Park Dr. E Montgomery, AL 36109 Ph: 334-277-8520 Fax: 334-272-7396 [email_address] www.jrsmith.com](https://image.slidesharecdn.com/trenchdrains-110819080734-phpapp02/85/Trench-Drain-Systems-Types-Benefits-Applications-and-Overview-28-320.jpg)