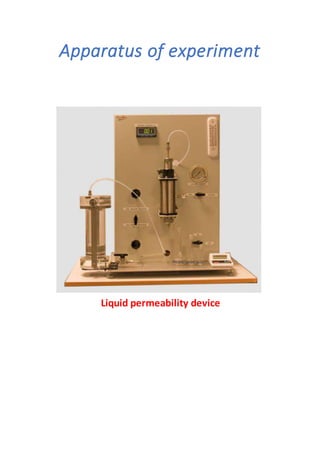

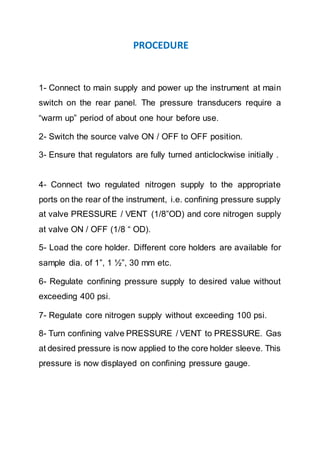

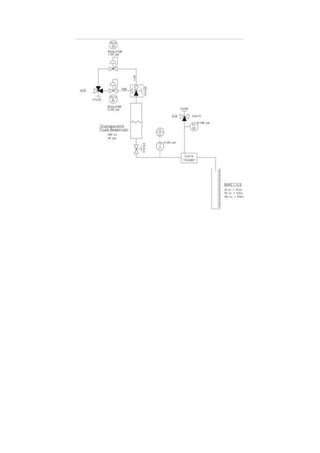

This document describes an experiment to determine the liquid permeability of a core sample using a liquid permeability device. The experiment involves applying confining pressure from a nitrogen gas supply, using another nitrogen gas supply to push water through the core sample, and measuring the flow rate and time taken to fill a graduated flask to calculate permeability based on Darcy's law. Safety warnings and references are also provided.

![Note

If on increasing pressure with LOW pressure regulator, the

maximum pressure is obtained without generating any significant

flow through the core, switch the HIGH regulator on.

As an example we have plotted the permeability for a core of dia.

1” and length 3 inch as a function of required time to fill the flask

10cc and 100 cc respectively. The upstream pressure is varied

from 1 to 100 psi and the flow duration is from 1 minute to 60

minutes.

6. Report file operation

Copy the template XLS report file into [Your Name]. xls (for

instance Monday.xls).

Open Monday.xls.](https://image.slidesharecdn.com/liquidpermeability-150731203150-lva1-app6892/85/Liquid-permeability-7-320.jpg)