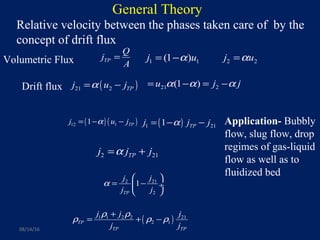

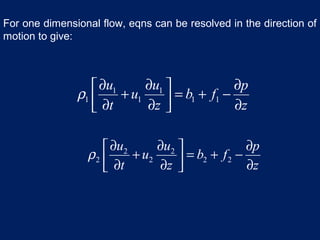

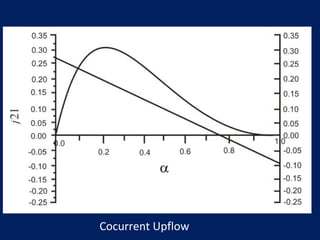

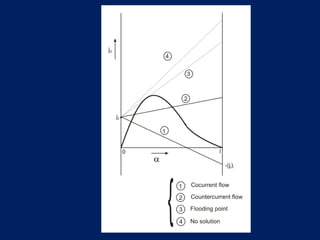

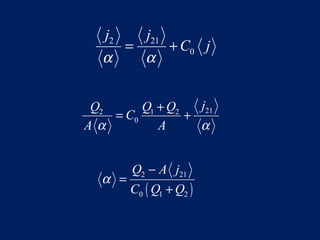

The drift flux model is applicable to two-phase flows like gas-liquid flows and fluidized beds. It accounts for the relative velocity between phases using the concept of drift flux. The model equations can be solved graphically or numerically to obtain void fraction and drift velocity for different flow regimes like cocurrent, countercurrent flows. Correlations are provided to estimate drift velocity and void profile parameter based on flow conditions.

![0

2

1

2

C

m n

= +

+ +

[1 ]wα

α

−

< >

0CEstimation of

For fully developed bubbly flow (Ishii)

0 0 ,

g

l l

GD

C C

ρ

ρ µ

= ÷

Assuming power law profiles for α and j](https://image.slidesharecdn.com/driftflux-160814081619/85/Drift-flux-31-320.jpg)

![For boiling bubbly flow in an internally heated annulus

3.12< >0.212

Co= 1.2 - 0.2 [1 - e ]

g

l

α

ρ

ρ

In downward two-phase flow for all flow regimes

0C =(- 0.0214<j*> + 0.772) + (0.0214<j*> + 0.228) for (-20) <j*> < 0

g

l

ρ

ρ

≤

0.00848[<j*>+20] 0.00848[<j*>+20]

oC =(0.2e +1) - 02e for < j*> < (-20)

g

l

ρ

ρ

÷

÷

Where <j*

> =

2 j

j

u](https://image.slidesharecdn.com/driftflux-160814081619/85/Drift-flux-33-320.jpg)

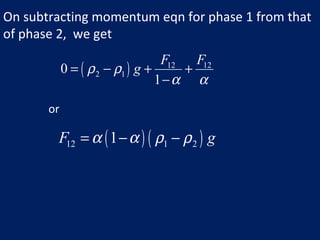

![08/14/16

INFLUENCE OF CONTAINING

WALLS

In finite vessel: ub

<u∞

ub

/u∞

=fn(d/D), D=Tube diameter

In region 5 for large inviscid bubbles

d/D < 0.125 , ub

/u∞

=1

0.125 < d/D < 0.6 , ub

/u∞

=1.13 e-d/D

0.6 < d/D , ub

/u∞

=0.496 (d/D)-1/2

[Bubbles behaves like slug flow bubbles in an inviscid fluid]](https://image.slidesharecdn.com/driftflux-160814081619/85/Drift-flux-40-320.jpg)

![08/14/16

INFLUENCE OF CONTAINING WALLS

CONTINUED

• In viscous fluids:

ub

/u∞

=[1+2.4(d/D)]-1

For bubbles behaving as solid spheres

ub

/u∞

=[1+1.6(d/D)]-1

For fluid spheres & µg

<< µf

If d/D > 0.6 ,ub

/u∞

=0.12 (d/D)-2

At d/D = 0.6 , ub

/u∞

= 1-(d/D)/0.9 ( used to estimate ub

for d/D <

0.6)](https://image.slidesharecdn.com/driftflux-160814081619/85/Drift-flux-41-320.jpg)