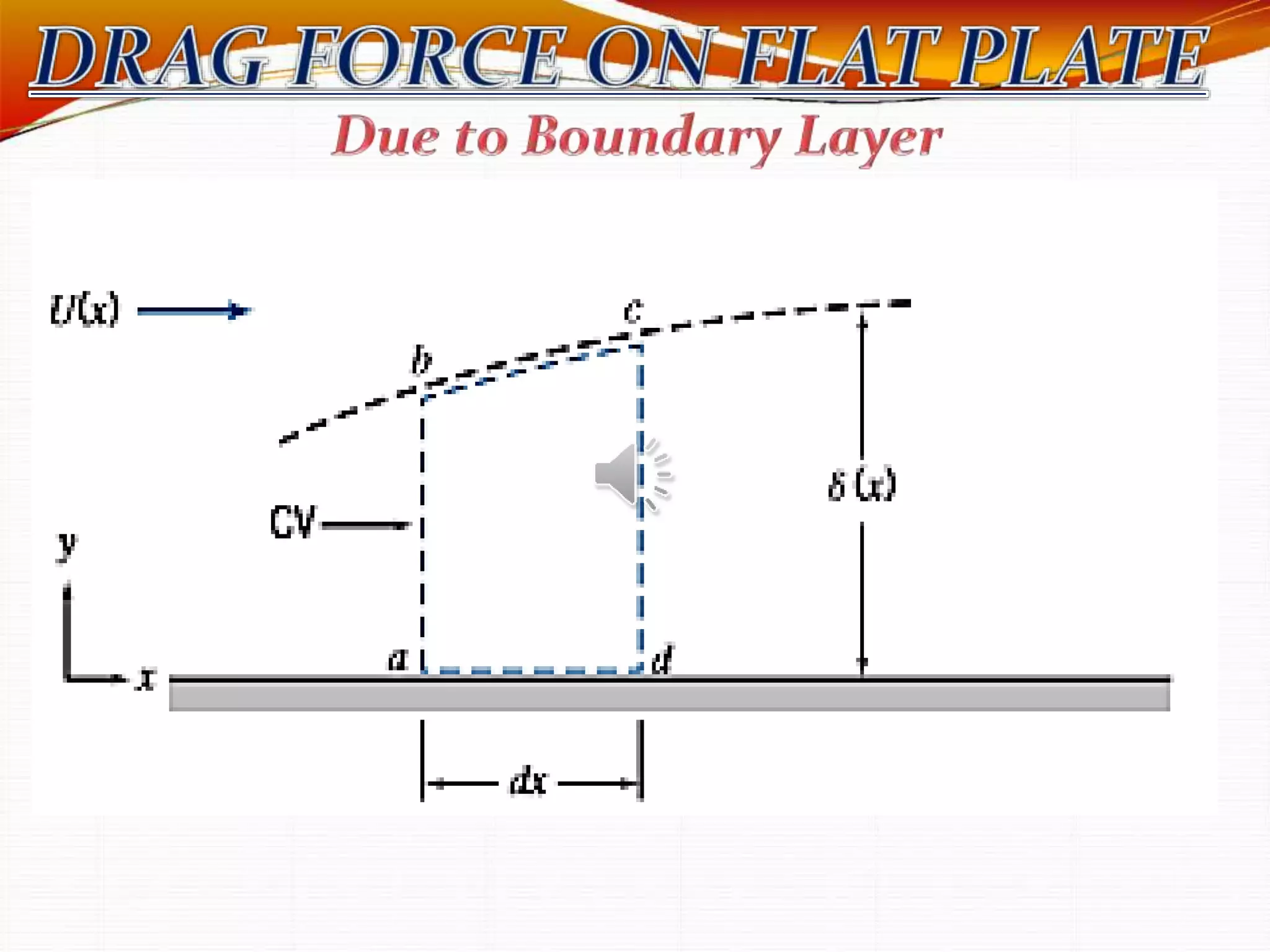

When a body moves through a fluid, it experiences two forces: drag and lift. Drag acts in the direction of flow and slows the body down, while lift acts perpendicular to flow. These forces depend on factors like the fluid's velocity, density, the body's size and shape, and its orientation to the flow. For streamlined bodies, drag is minimized by reducing pressure drag from separated or turbulent flow. Blunt bodies experience greater pressure drag due to larger separated regions behind them. The boundary layer concept is used to analyze fluid forces on a body by considering the very thin layer of slowed fluid near the body's surface.

![The shear stress is given by

=(μ 𝜕𝑢

)𝜕𝑦 y=0

Drag force or shear force on the small distance is given by

∆Fd= ∆xb

Drag force ∆Fdmust be equal to the rate of change of momentum over

the distance ∆x

The mass rate of flow entering through AD

= 0∫ (ρ× velocity × area of thickness dy)

= 0∫ ρubdy

The mass rate of flow leaving side BC

𝜕

𝑥

mass through AD+ 𝜕

(mass through AD)×∆𝑥

0

= 𝛿

𝜌𝑢𝑏𝑑𝑦 +

𝜕

[

𝜕𝑥 0

𝛿

𝜌𝑢𝑏𝑑𝑦]∆𝑥

From continuity equation for a steady incompressible flow ,we have

MAD +MDC =MBC](https://image.slidesharecdn.com/dragforceliftforce-190316100529/75/Drag-force-lift-force-29-2048.jpg)

![MDC = MBC – MAD

𝜕 𝛿

= 𝜕𝑥 0 [𝜌𝑢𝑏𝑑𝑦]∆x

𝛿

momentum flux entering through AD= 0 [𝜌𝑢𝑏𝑑𝑦]x [u]

0

𝛿

= 𝜌u2bdy

𝜕

𝑥

0 0

𝛿 𝜕 𝛿

Momentum flux entering through sideBC = 𝜌u2bdy = [ 𝜌u2bdy] ∆𝑥

𝜕

𝑥

0

𝜕 𝛿

So, momentum flux throughDC = [ 𝜌ubdy] ∆𝑥 x U

Rate of change of momentum of control volume = MFBC -MFAD –MFDC

𝜕

𝑥

0 0

𝛿 𝜕 𝛿

{ 𝜌u2bdy + [ 𝜌u2bdy] ∆𝑥}-{ 0

𝛿 2𝜌u bdy}-{

𝜕

𝜕

𝑥

0

𝛿

[ 𝜌ubdy] ∆𝑥 x u}

𝜕

𝑥

0

= 𝜌𝑏 𝜕

[

𝛿

(𝑢2 -𝑢𝑈)𝑑𝑦] ×∆𝑥](https://image.slidesharecdn.com/dragforceliftforce-190316100529/75/Drag-force-lift-force-30-2048.jpg)

![Total external force is in the direction of rate of change of

momentum;

𝜕𝑥 0

-𝜏∆𝑥b =𝜌𝑏 𝜕

[

𝛿

(𝑢2 -𝑢𝑈)𝑑𝑦] × ∆𝑥

𝜏

𝜌𝑢2 𝜕𝑥 0 𝑈 𝑈

= [ 𝜕 𝛿 𝑢

(1- 𝑢

) 𝑑𝑦]

𝜏

𝜌𝑢2

=

𝜕

𝜃

𝜕𝑥

Where ; θ= Momentum thickness

This is Von karman momentum integral equation

This equation is applicable for all type of boundary layers.](https://image.slidesharecdn.com/dragforceliftforce-190316100529/75/Drag-force-lift-force-31-2048.jpg)

![Local coefficient of Drag [CD *]

DC * =

𝜏

𝑈2 𝜌

2

Average drag coefficient [CD ]

DC =

𝐹 𝐷

𝑈2 𝐴 𝜌

2

Where; A = Area ofplate

U= free stream velocity

ρ=mass density of fluid](https://image.slidesharecdn.com/dragforceliftforce-190316100529/75/Drag-force-lift-force-32-2048.jpg)

![Expression for CD for Reynolds number less than 0.2

FD = CD

2

A 𝜌𝑈

2

FD =3𝜋𝜇𝐷𝑈

Equating both we get;

3𝜋𝜇𝐷𝑈 =C D

2

A 𝜌𝑈

2 4

2

TakeA= 𝜋𝐷

;

CD

= 24

𝑅 𝑒

Expression for CD when 0.2< Re <5

DC = 24

[1+

3

𝑅 𝑒 16𝑅 𝑒

]

Note: 1:) for 5<Re <1000; CD =0.4

2:) For 103 <Re <105; CD = 0.5

3:)For Re >105 ; CD =0.2

](https://image.slidesharecdn.com/dragforceliftforce-190316100529/75/Drag-force-lift-force-36-2048.jpg)