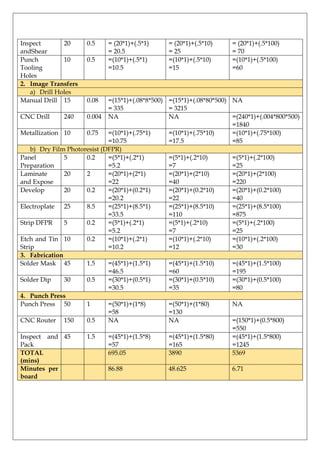

Donner Company accepts orders of varying sizes, from small to large. This causes issues for their shop floor and performance. Taking both small and large orders leads to inefficient scheduling and idle workers as manual and automated processes require different staffing levels. It also increases returns and delays, as larger orders are more difficult for Donner to complete accurately due to incomplete operations and quality issues. Accepting both small and large orders makes it hard to assess worker performance and impacts key metrics like average flow time, on-time shipment, and quality levels.