- Donner Company was founded in 1985 and specialized in manufacturing circuit boards for prototype and small production runs. It promised delivery within 3-5 weeks depending on order size.

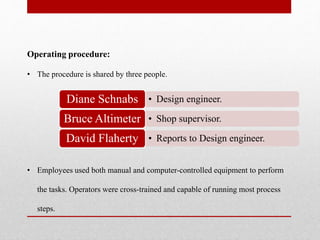

- The manufacturing process involved three steps: preparation, image transfer, and fabrication. It was carried out by three employees using both manual and computer-controlled equipment.

- Problems faced by the company included being overly crowded in the second half of the month, increasing rates of returns, and an unstable production process due to bottlenecks and frequent rescheduling.