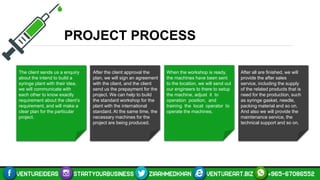

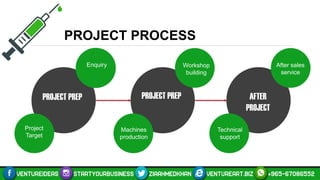

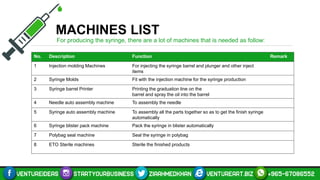

The document outlines the process of establishing a syringe manufacturing plant, including client communication, project planning, workshop construction, machine production, and after-sales service. It details the roles of key project team members, the machinery required for production, and the steps involved in manufacturing, sterilizing, and packaging syringes. Additionally, it emphasizes the importance of quality materials, effective training, and technical support in maintaining production efficiency.