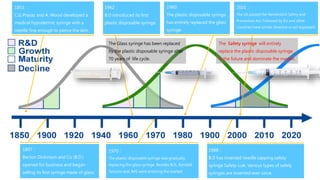

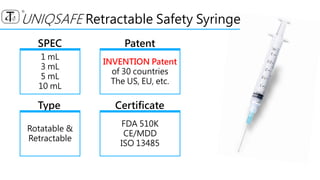

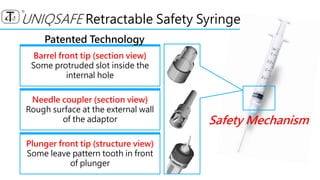

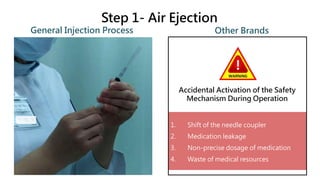

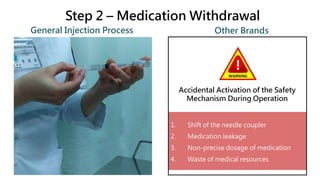

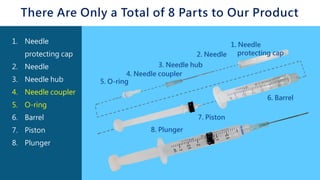

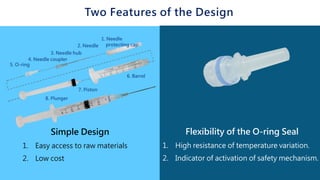

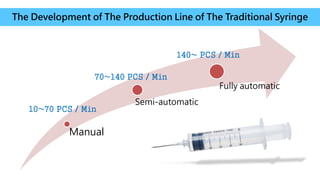

This document introduces the UNIQSAFE Retractable Safety Syringe produced by Axel Bio Corporation. It summarizes global trends towards using safety syringes to prevent needlestick injuries. The UNIQSAFE syringe uses a patented retractable mechanism that allows for identical operation to traditional syringes while providing enhanced safety. It aims to replace traditional syringes by offering simple use, minimal training requirements, and mechanical retraction to eliminate malfunctions. The syringe can be produced at low cost using an efficient production line with only 8 parts.