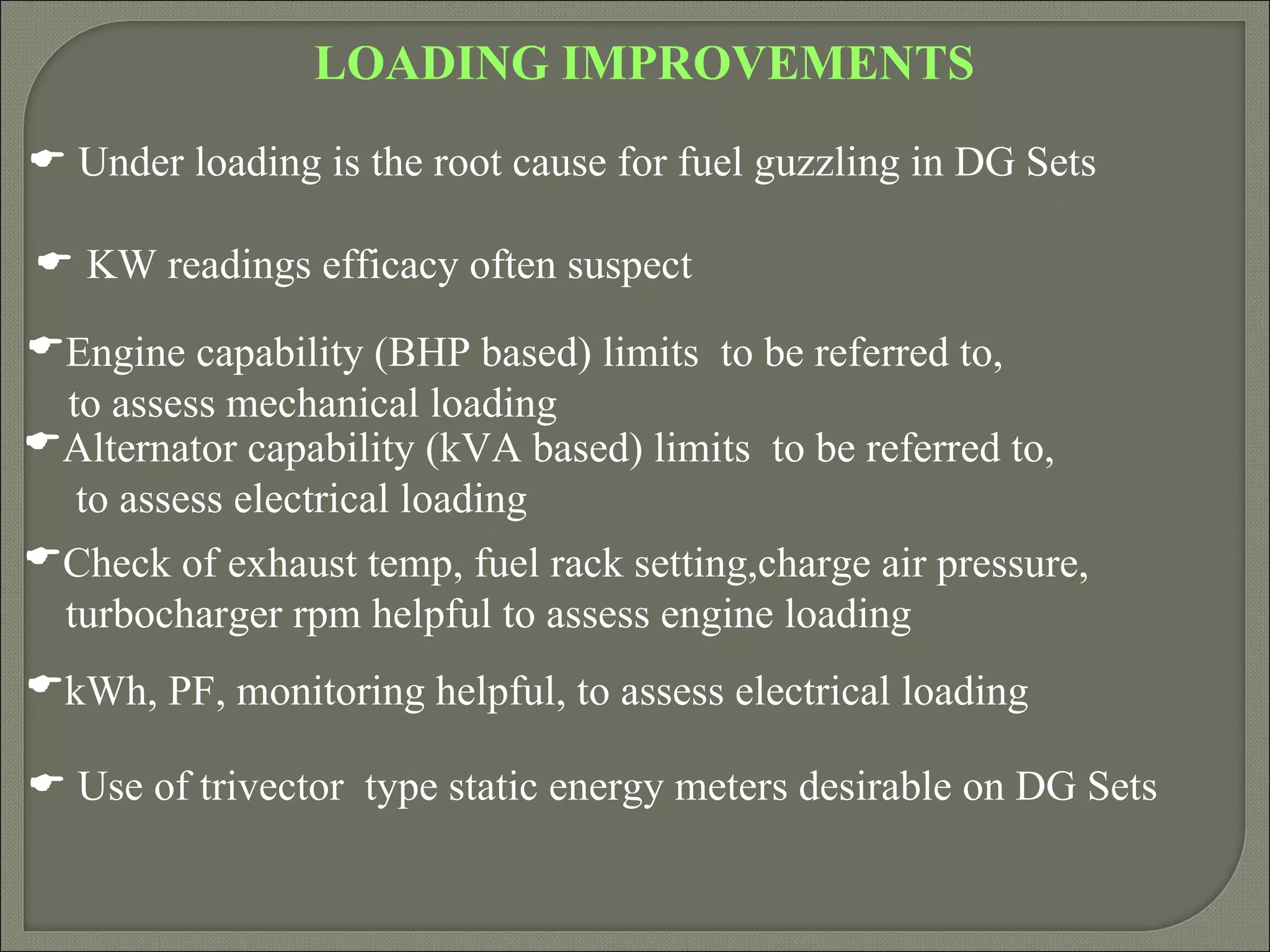

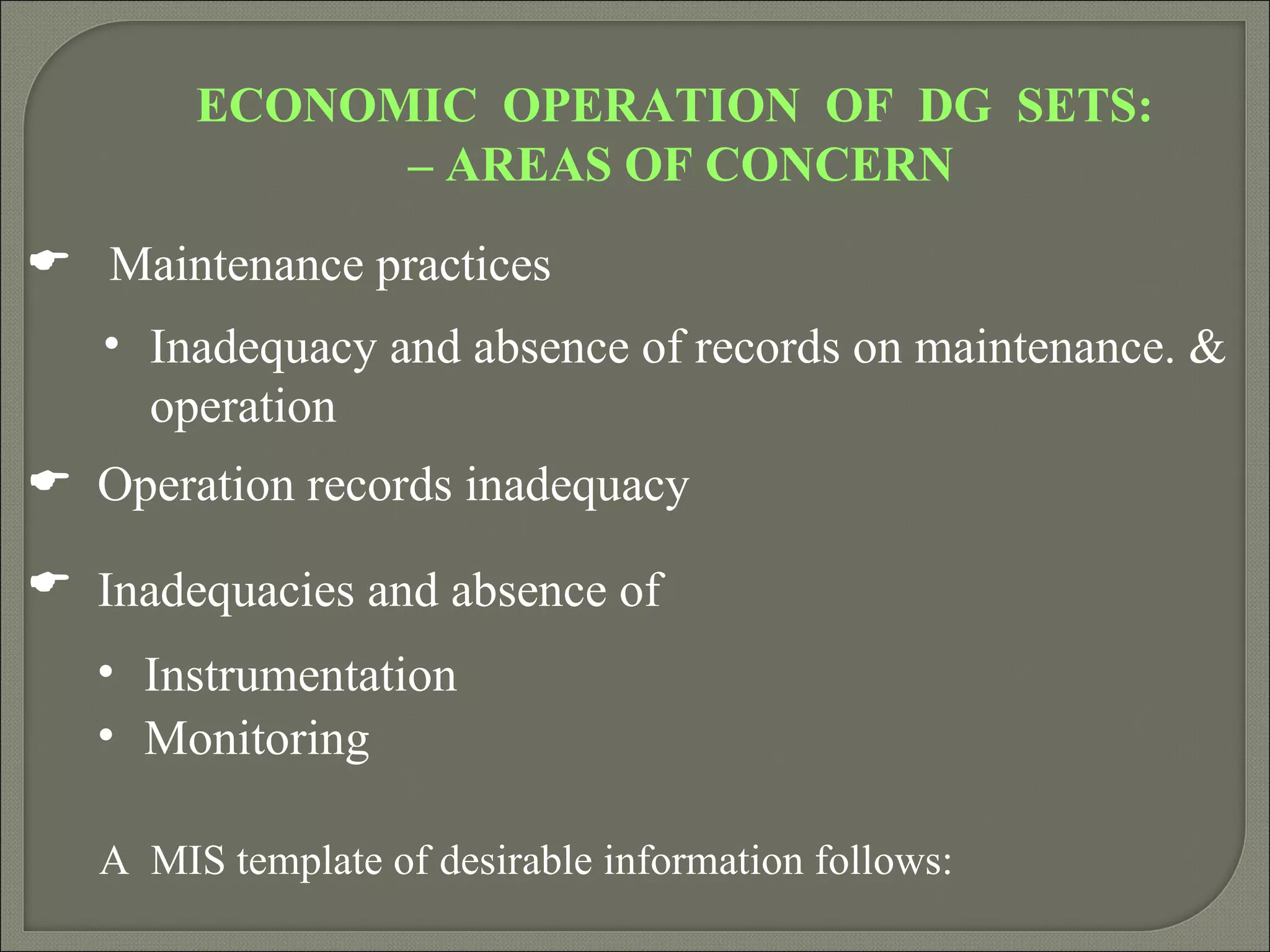

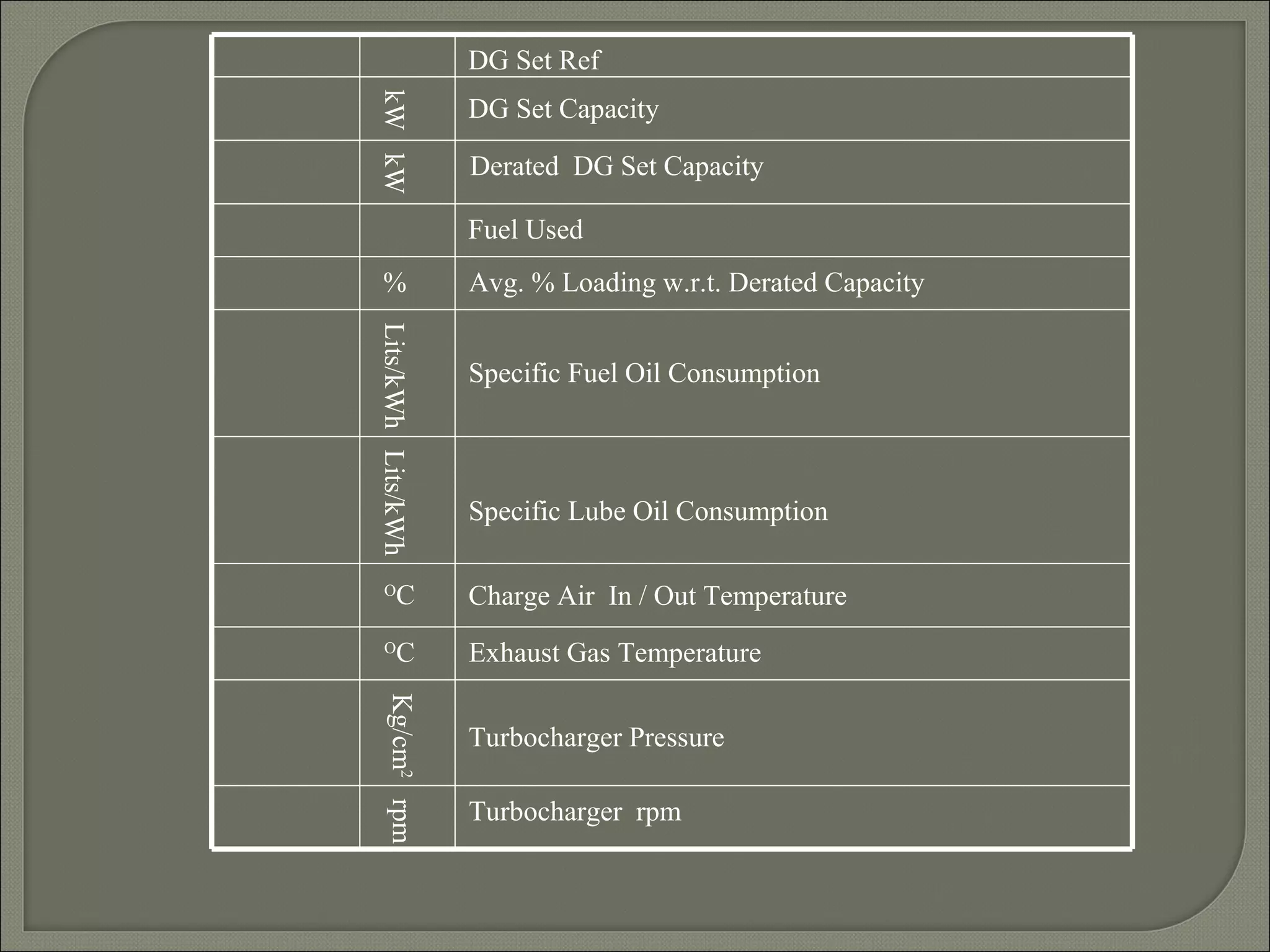

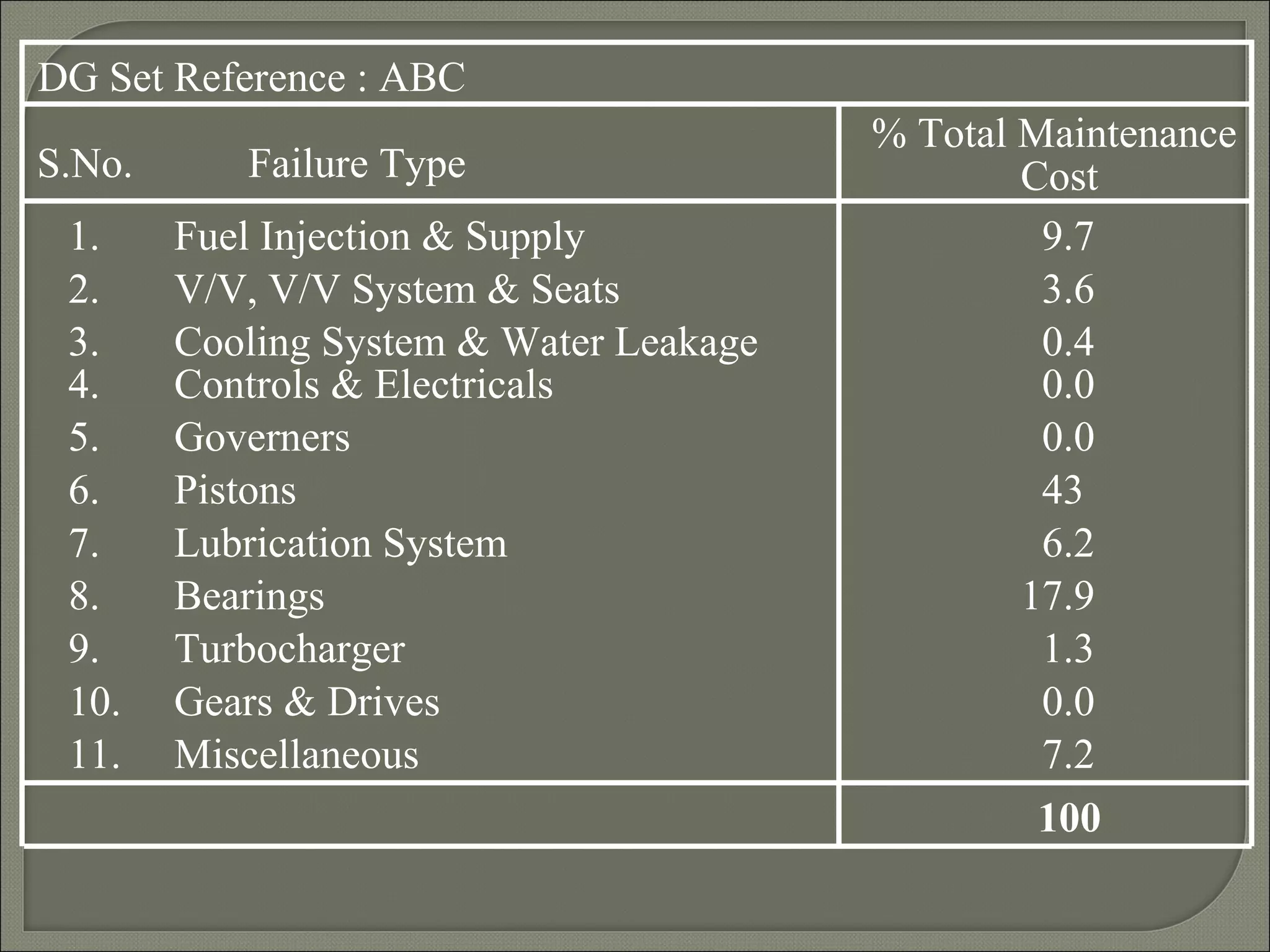

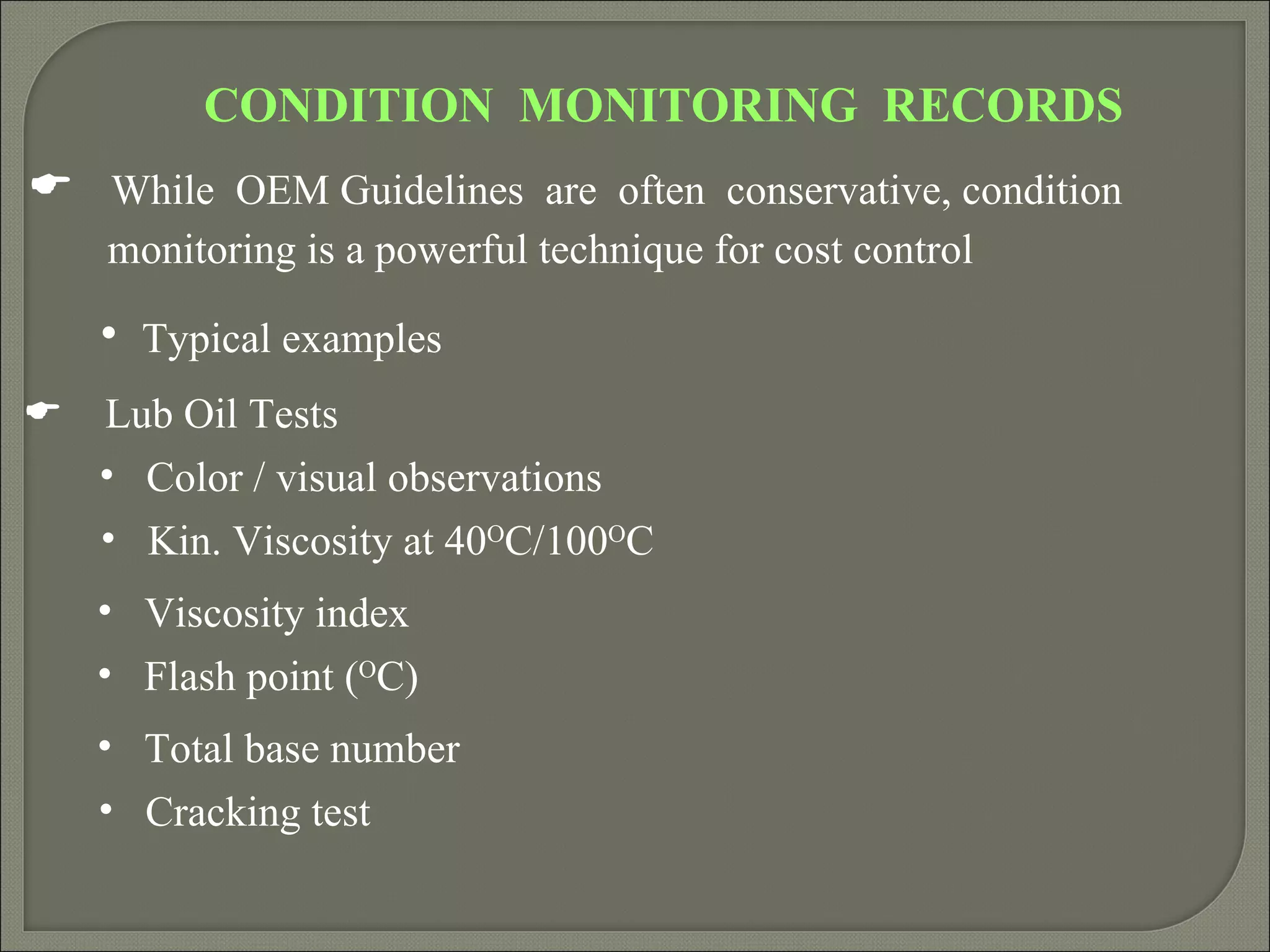

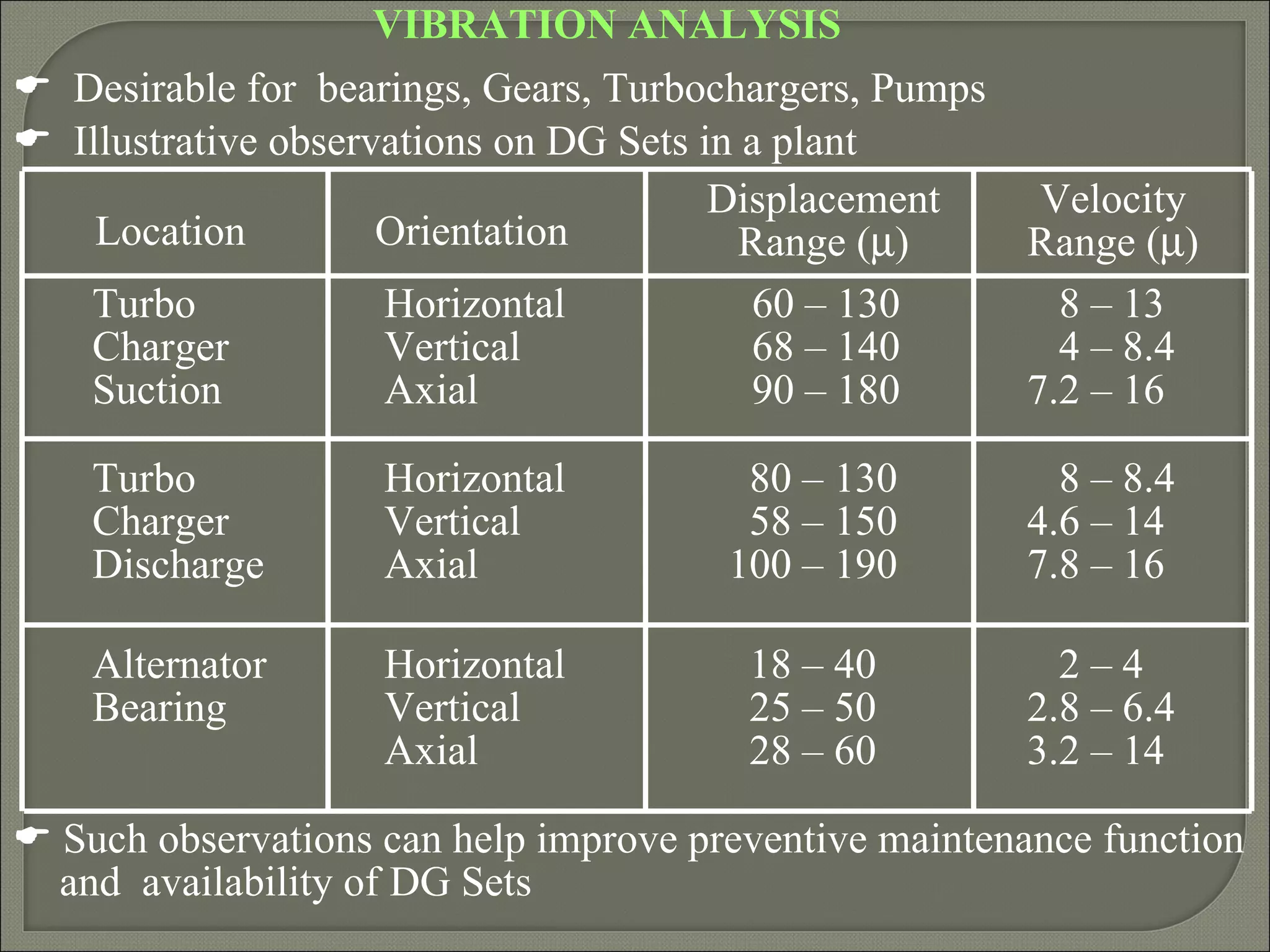

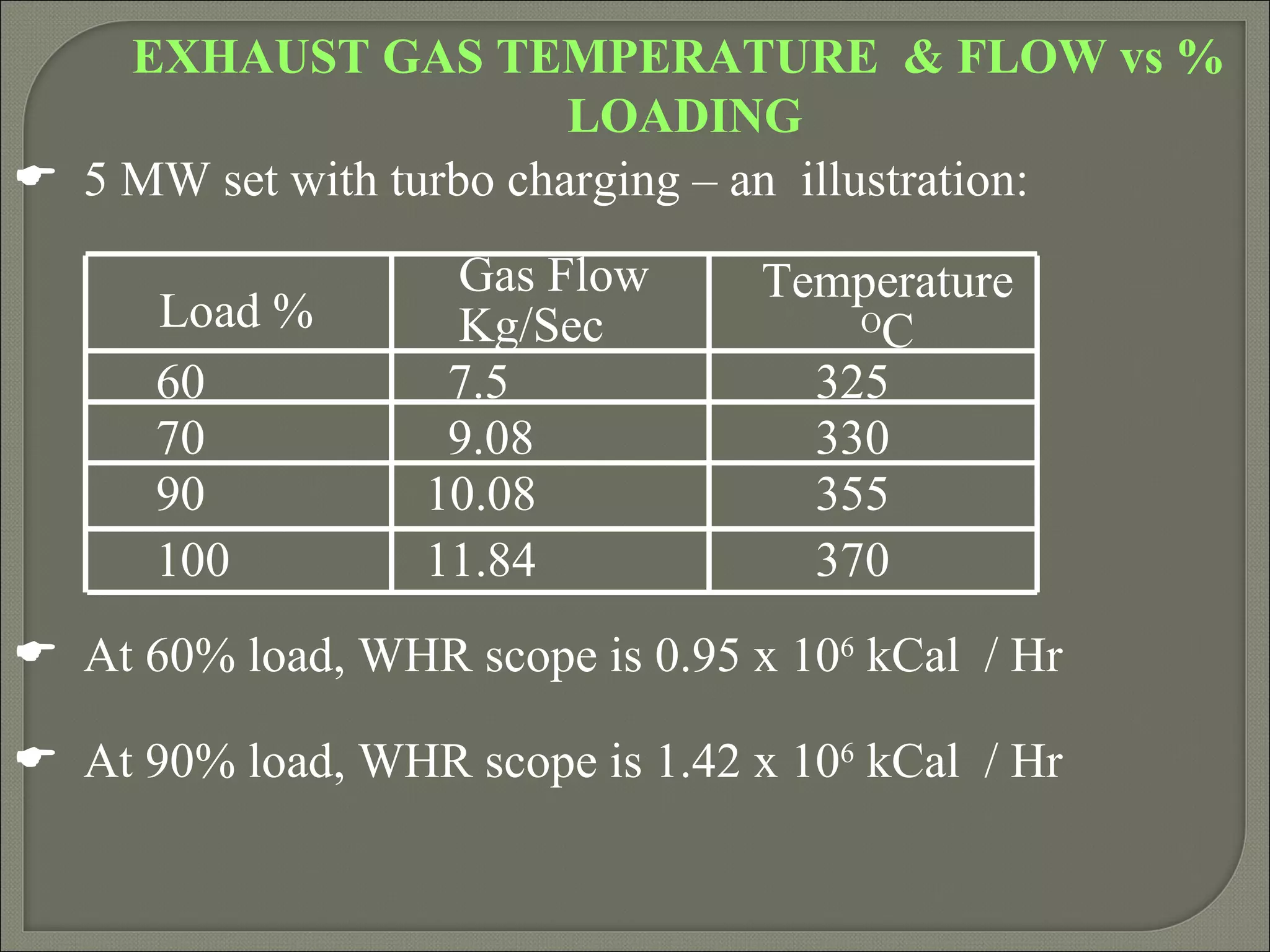

This document discusses options for economic operation of diesel generator sets for captive power generation. It outlines the typical advantages of captive generation such as ensuring power quality and offsetting transmission and distribution losses. It then describes different captive power options available, highlighting that diesel generator sets are attractive due to their low implementation period, efficiency, and investments compared to other options. The document also discusses measures to improve the economic operation of diesel generator sets such as improving loading, parallel operations, maintenance practices, and harnessing waste heat recovery potential.