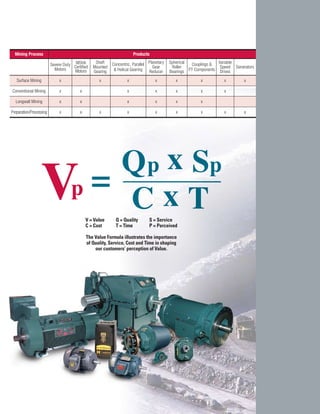

The document summarizes Baldor Electric's product offerings for the mining industry. It states that Baldor Electric provides a complete line of reliable power transmission products like motors, gearing, variable speed drives, and other components that are designed specifically for mining operations and ensure maximum uptime. The products are application-specific solutions for different types of mining processes and are engineered to perform reliably in severe mining environments.