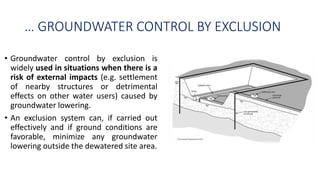

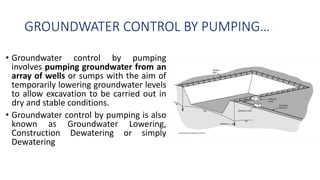

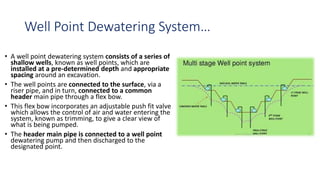

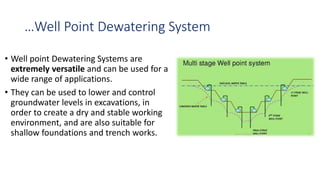

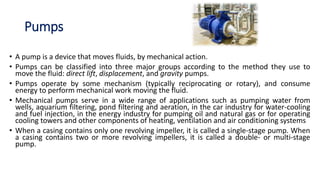

The document outlines dewatering methods for managing groundwater during basement construction. It discusses groundwater control techniques, including exclusion methods like cut-off walls and pumping methods using various well types, emphasizing the importance of groundwater management to avoid excavation-related problems. Additionally, it covers waterproofing methods to prevent water ingress in buildings and provides an overview of different pump types and their applications.