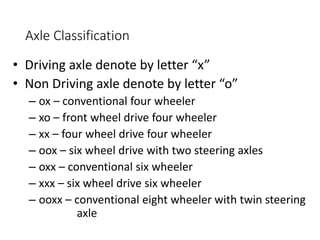

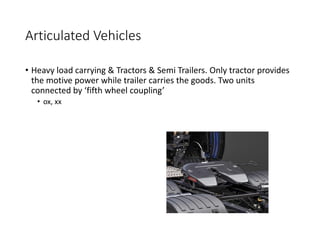

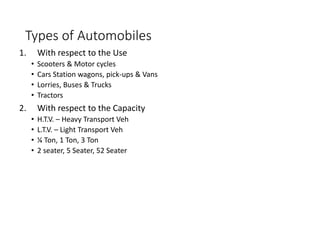

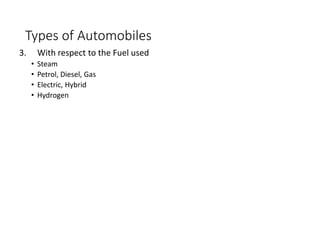

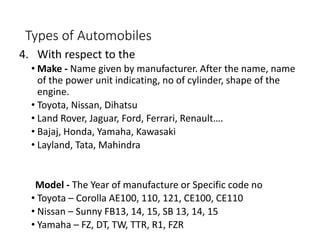

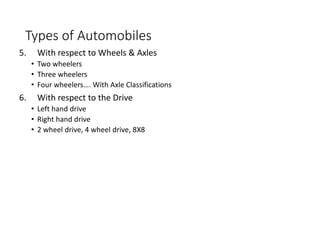

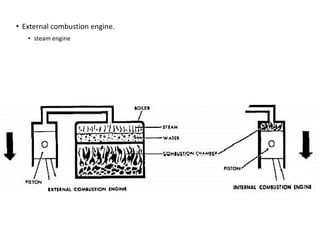

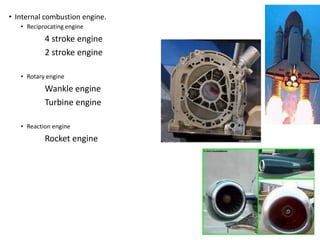

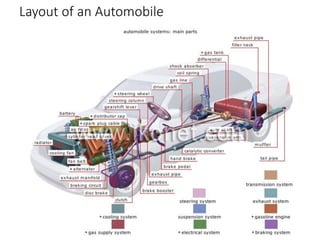

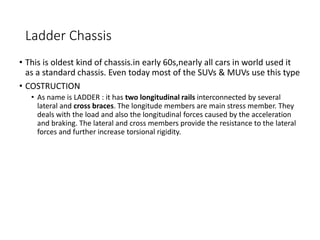

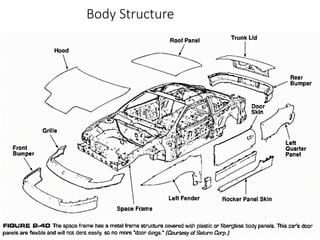

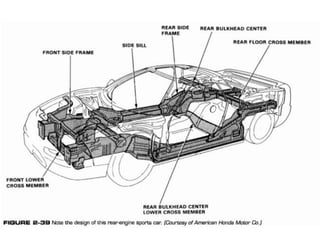

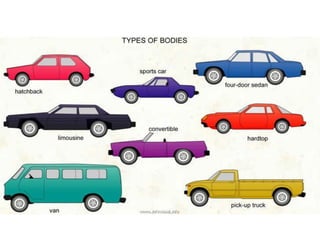

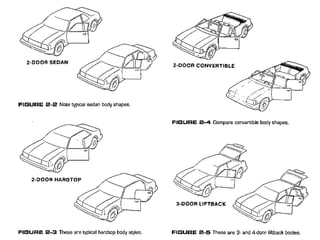

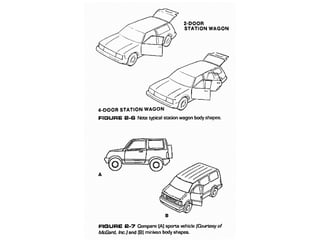

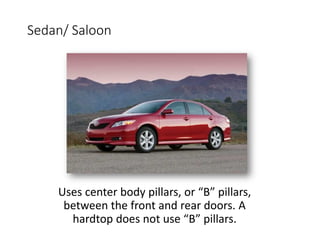

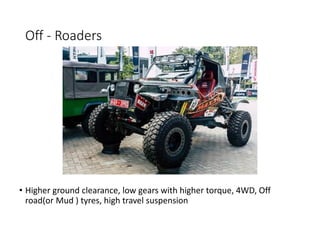

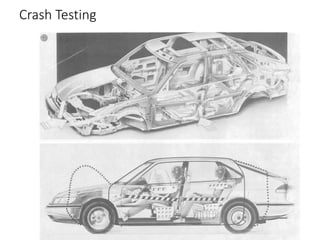

This document provides an overview of automobile classification systems. It begins by generally classifying vehicles as single-unit vehicles or load carriers and articulated vehicles. It then discusses axle classification systems using letters to denote driving and non-driving axles. Specific types of automobiles are also classified based on use, capacity, fuel used, make and model, wheels/axles, drive type, engine, suspension, transmission, and body style. Common body styles like sedan, hatchback, and SUV are defined. The document concludes with a brief overview of crash testing and the evolution of automotive safety features.