The document discusses a case involving ITT Automotive's development of a new generation antilock brake system (ABS) called the MK 20. Senior management favors using a highly automated single production process across four plants, but US plant managers prefer less automation for flexibility.

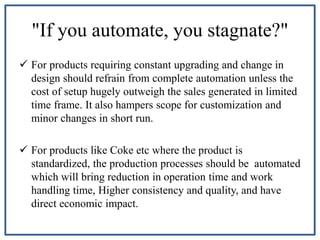

There are benefits to automation like lower costs and higher quality, but it reduces flexibility for customization and continuous improvement. While standardization improves efficiency, differences across plants in costs and customers should be considered. Plant managers may resist loss of flexibility, so their concerns around automation stagnating processes need to be addressed. Overall options chosen should fit ITT's strategy of reducing costs for popular affordable ABS systems.