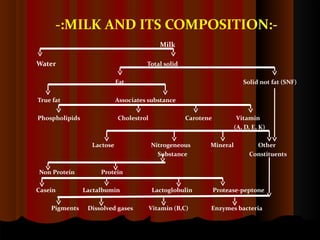

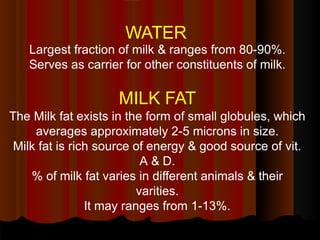

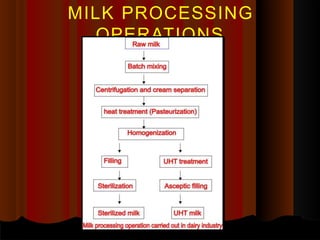

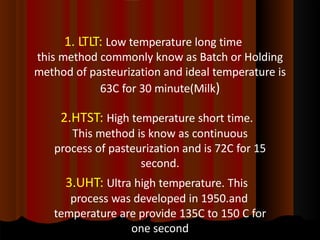

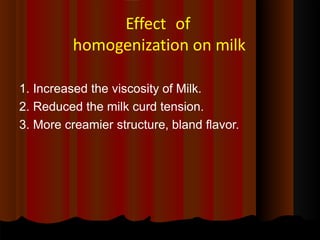

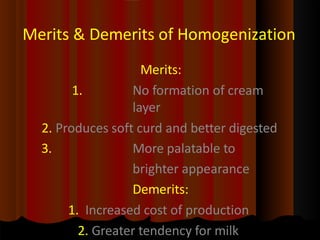

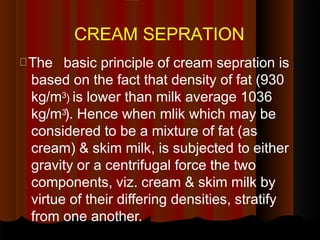

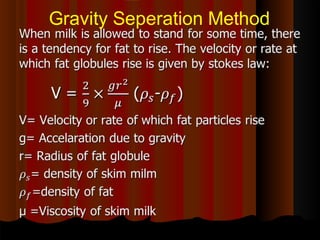

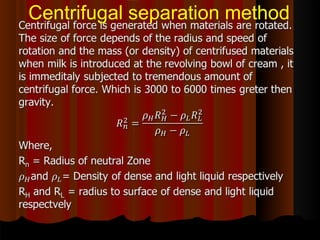

This document provides an overview of milk processing operations. It begins with definitions of milk and its composition. The key components of milk discussed include water, fat, proteins, lactose, enzymes, vitamins, and minerals. The document then covers several milk processing operations, including pasteurization methods like low-temperature long-time and high-temperature short-time. Other operations discussed are homogenization, cream separation via gravity or centrifugal methods, standardization, and mixing ingredients.