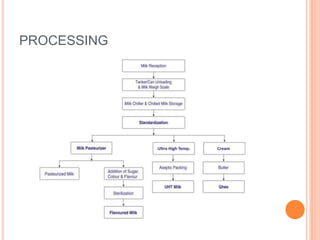

This document summarizes the key aspects of operating a milk processing plant, including site selection, operations, collection, processing, and products. An ideal site is centrally located near transportation and a water source. Operations include standardization, heat treatment, inoculation, and churning. Milk is collected from farms using cans and transported to the processing facility. Processing involves reception, storage, separation, heating, and cooling. The plant produces products like pasteurized, homogenized, whole, skimmed, and flavored milks, as well as paneer, shrikhand, ghee, and lassi.