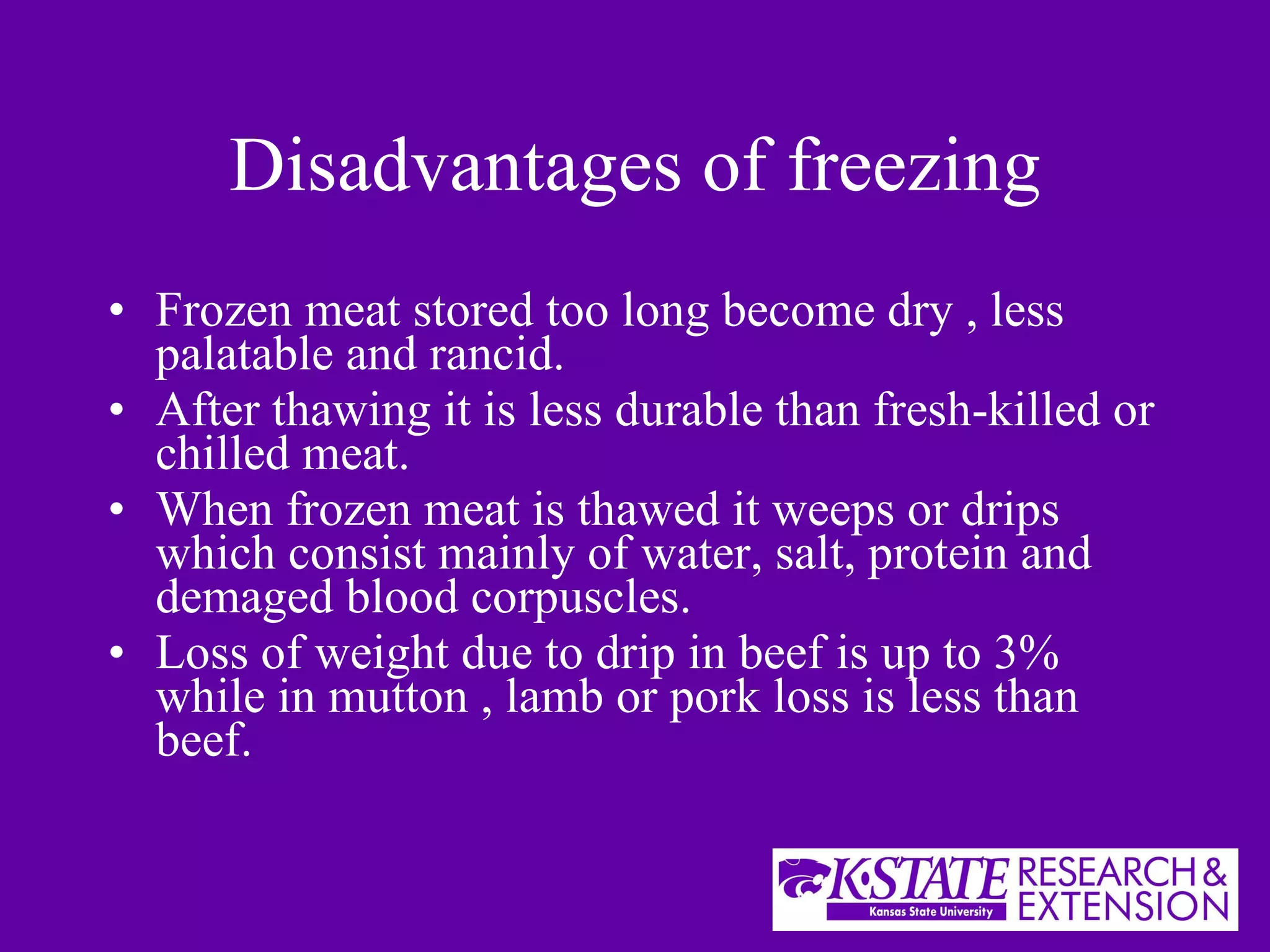

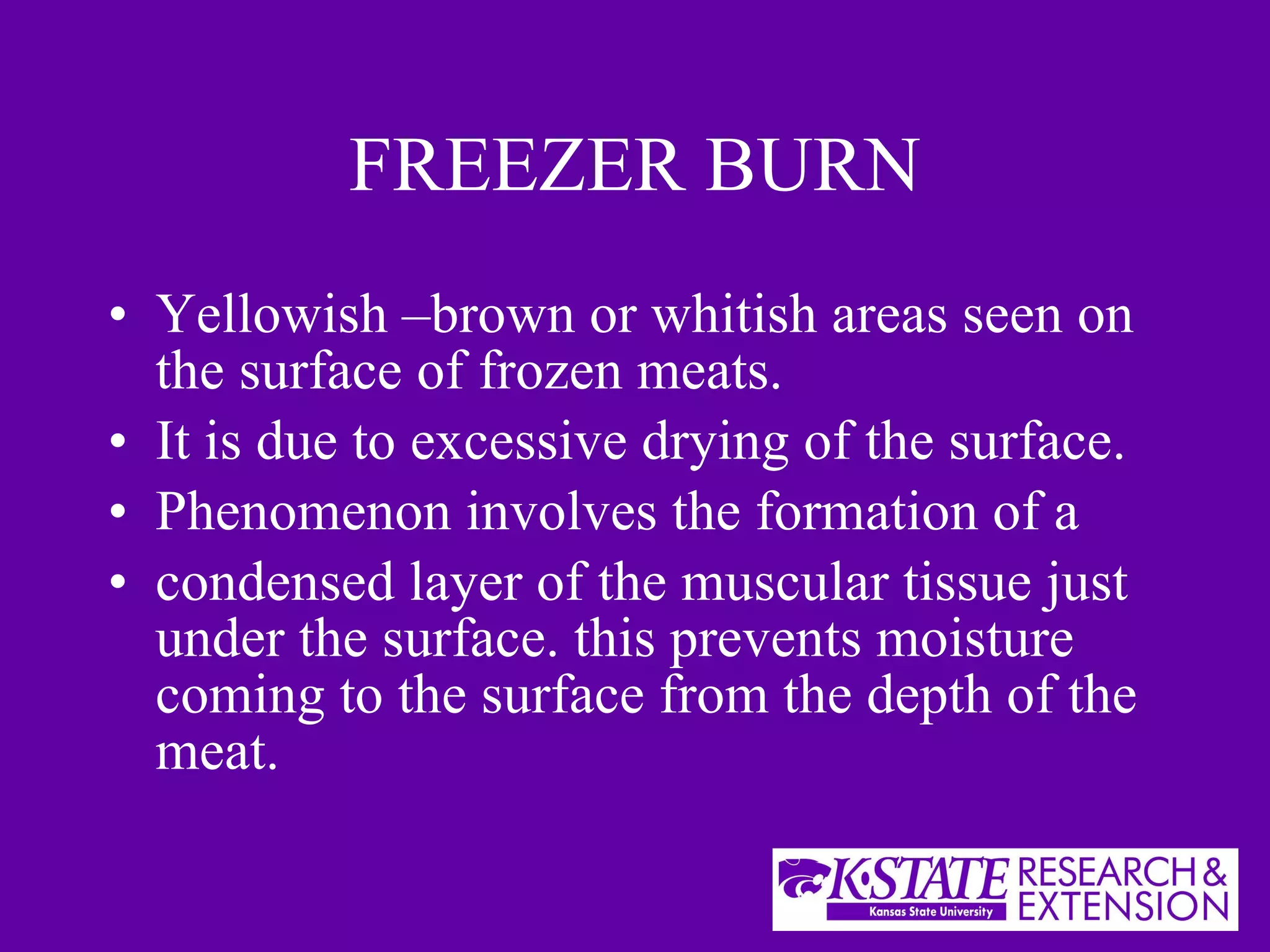

The document discusses various methods for preserving meat, including freezing, cooking, drying, chemical preservation, fermentation, irradiation, canning, vacuum packing, and curing. It explains how each method works to inhibit bacterial growth and spoilage by removing water, raising or lowering the temperature, changing the pH, or using other techniques to make the environment inhospitable for microorganisms. The key factors in meat preservation are controlling temperature, moisture level, pH, and atmospheric conditions.

![Questions Please contact Dr. Elizabeth Boyle or Ryan Timm at (785)532-1247 email: [email_address] [email_address] Please contact Dr.M.Arshad.Javid email: [email_address] OR Call your county extension office](https://image.slidesharecdn.com/ksumeatpreservation-120205040048-phpapp01/75/Ksu-meat-preservation-41-2048.jpg)