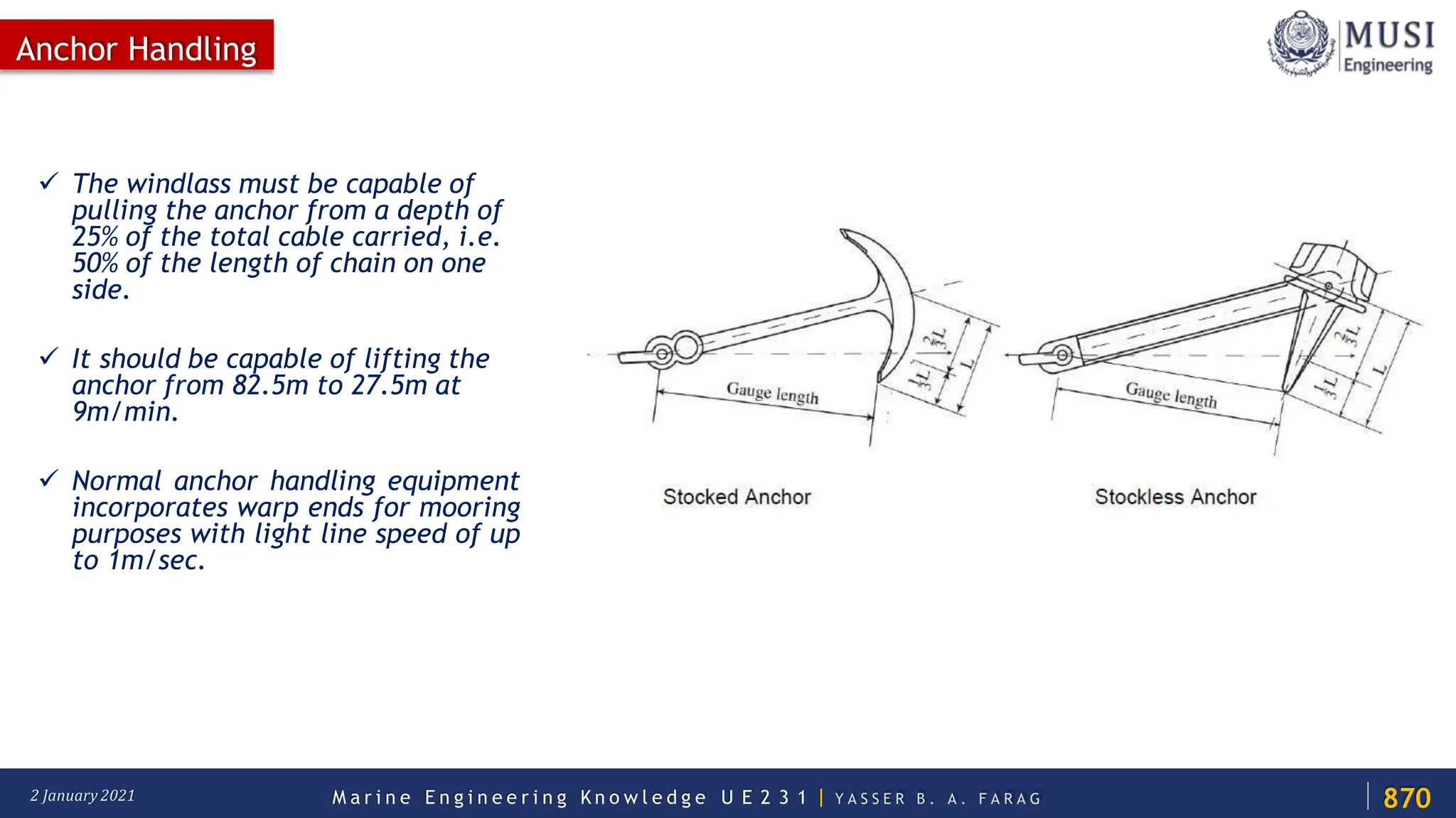

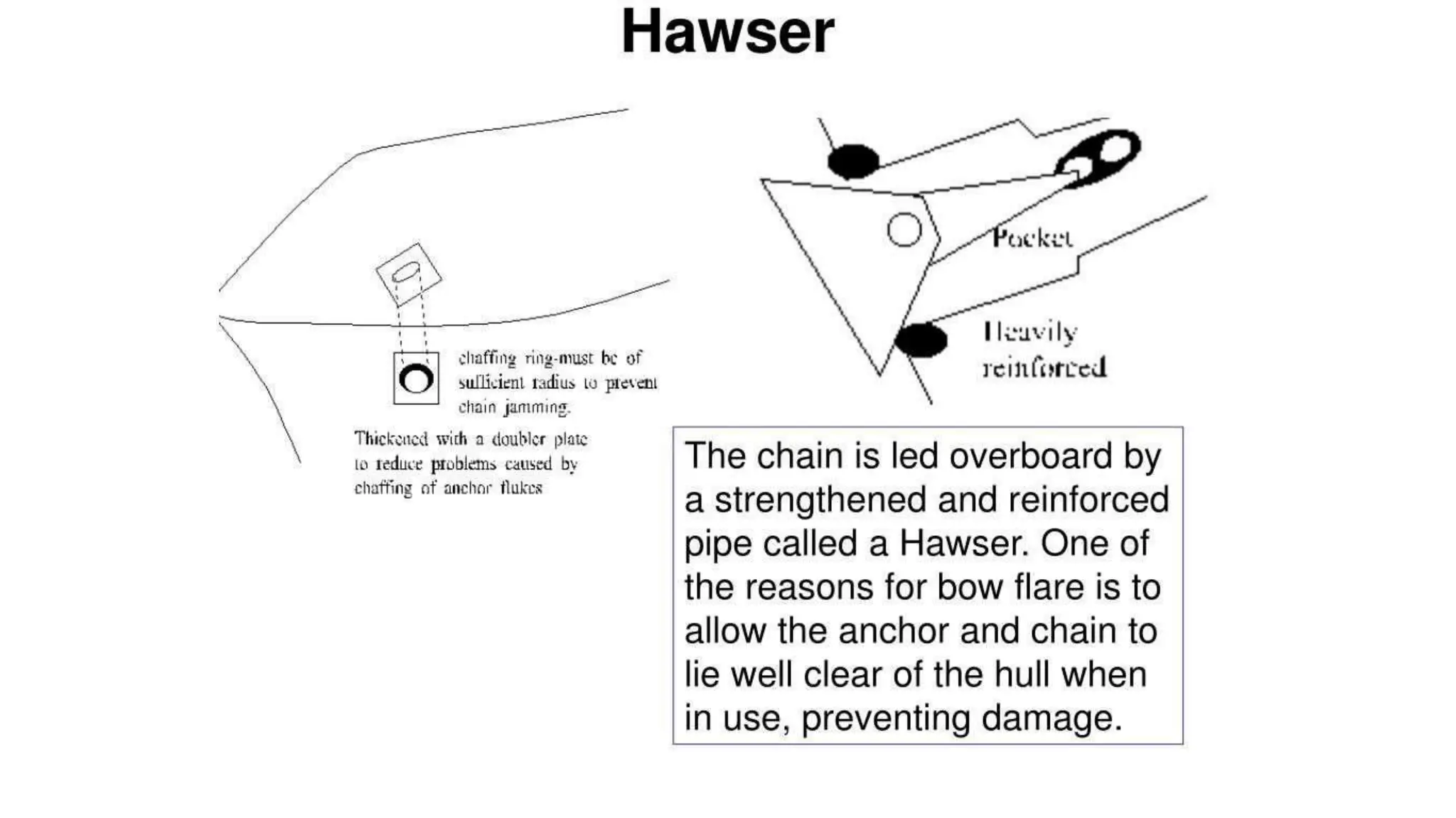

The document discusses ship deck machinery, which includes essential equipment for dock operations, cargo handling, and passenger transfers. It covers various types of deck machinery like winches, anchors, and mooring systems, detailing their operations, power sources, and configurations. The document emphasizes the importance of these systems for safe and efficient ship handling and highlights the functions, designs, and performance requirements of different marine equipment.