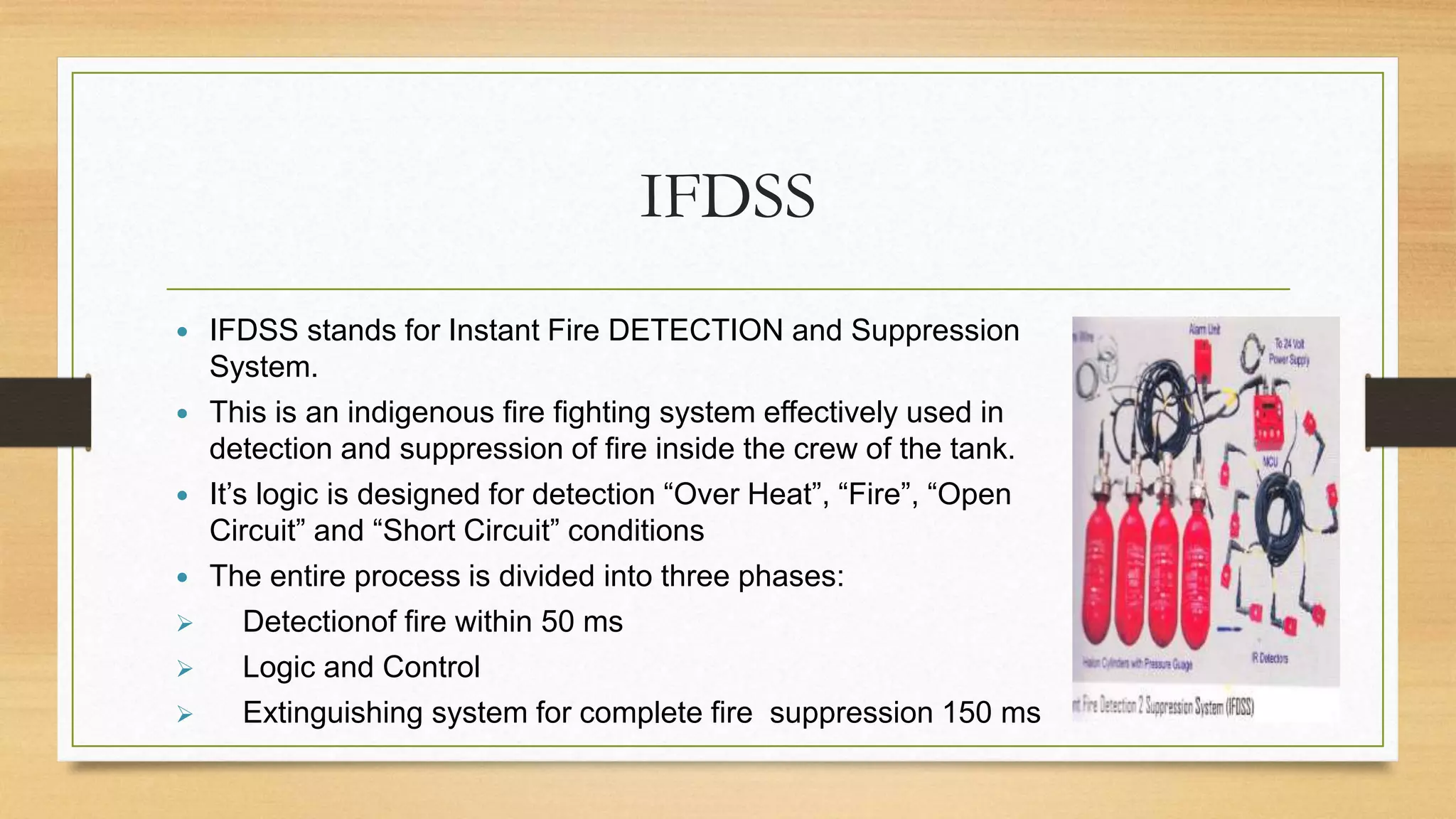

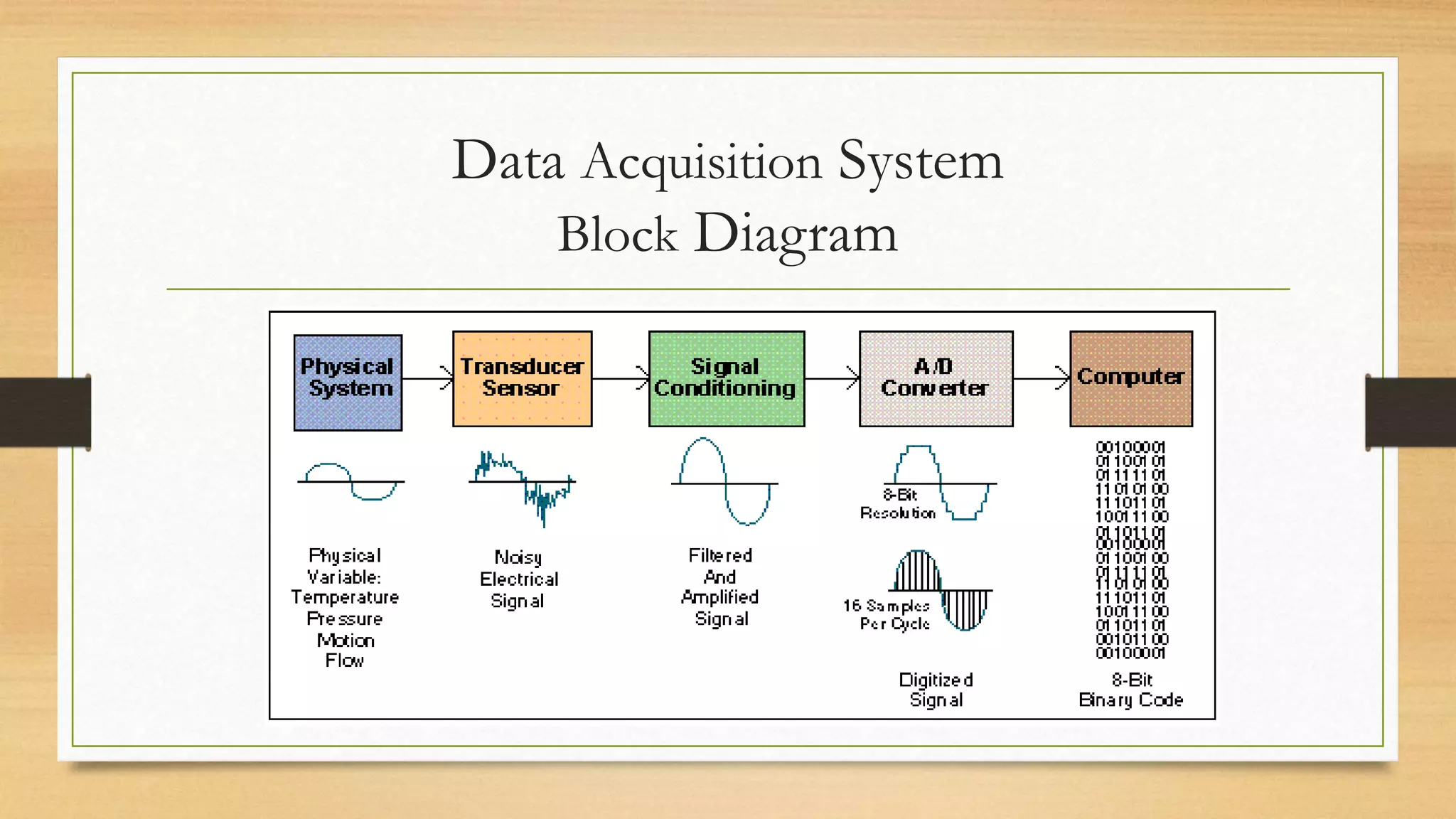

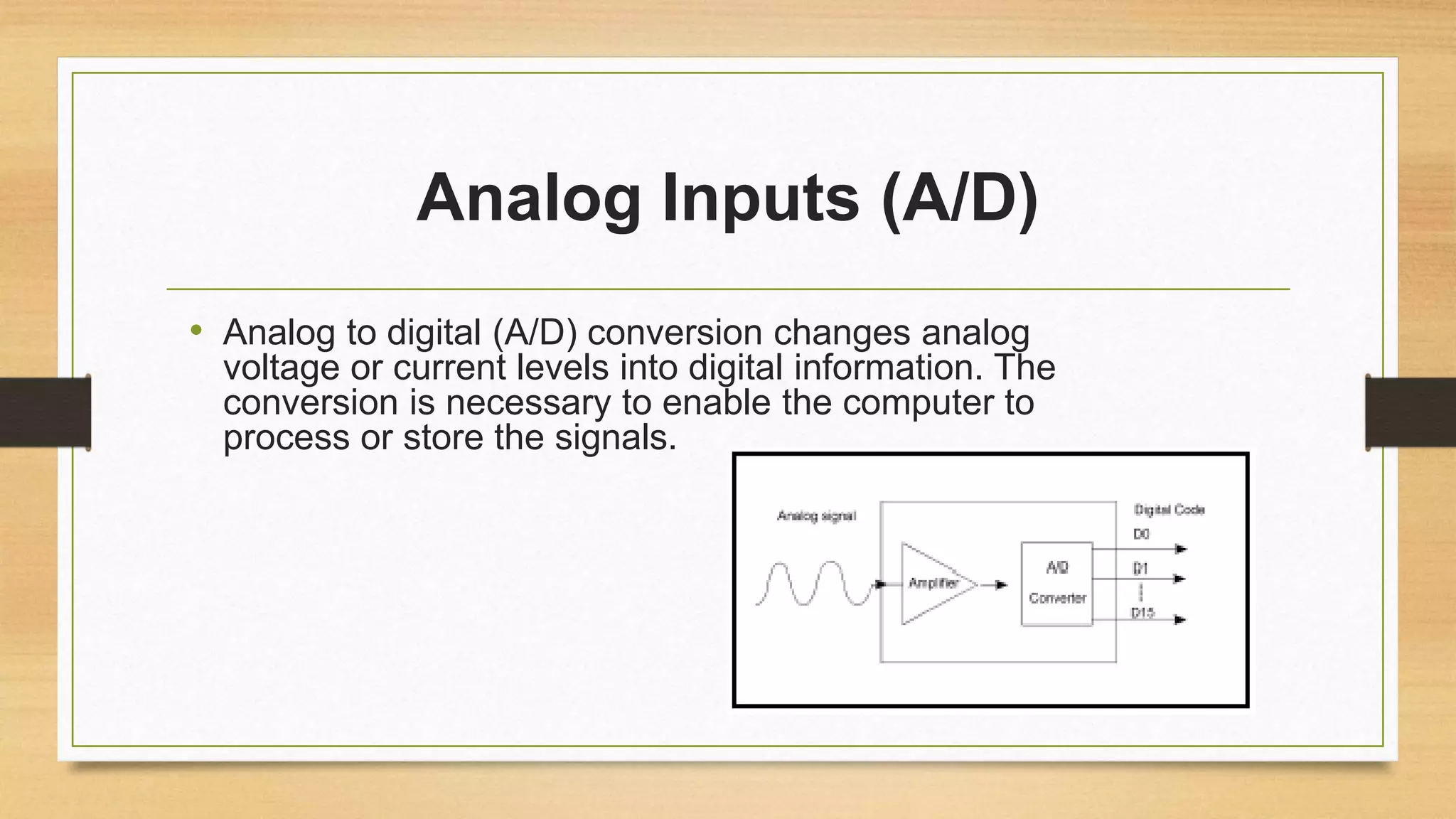

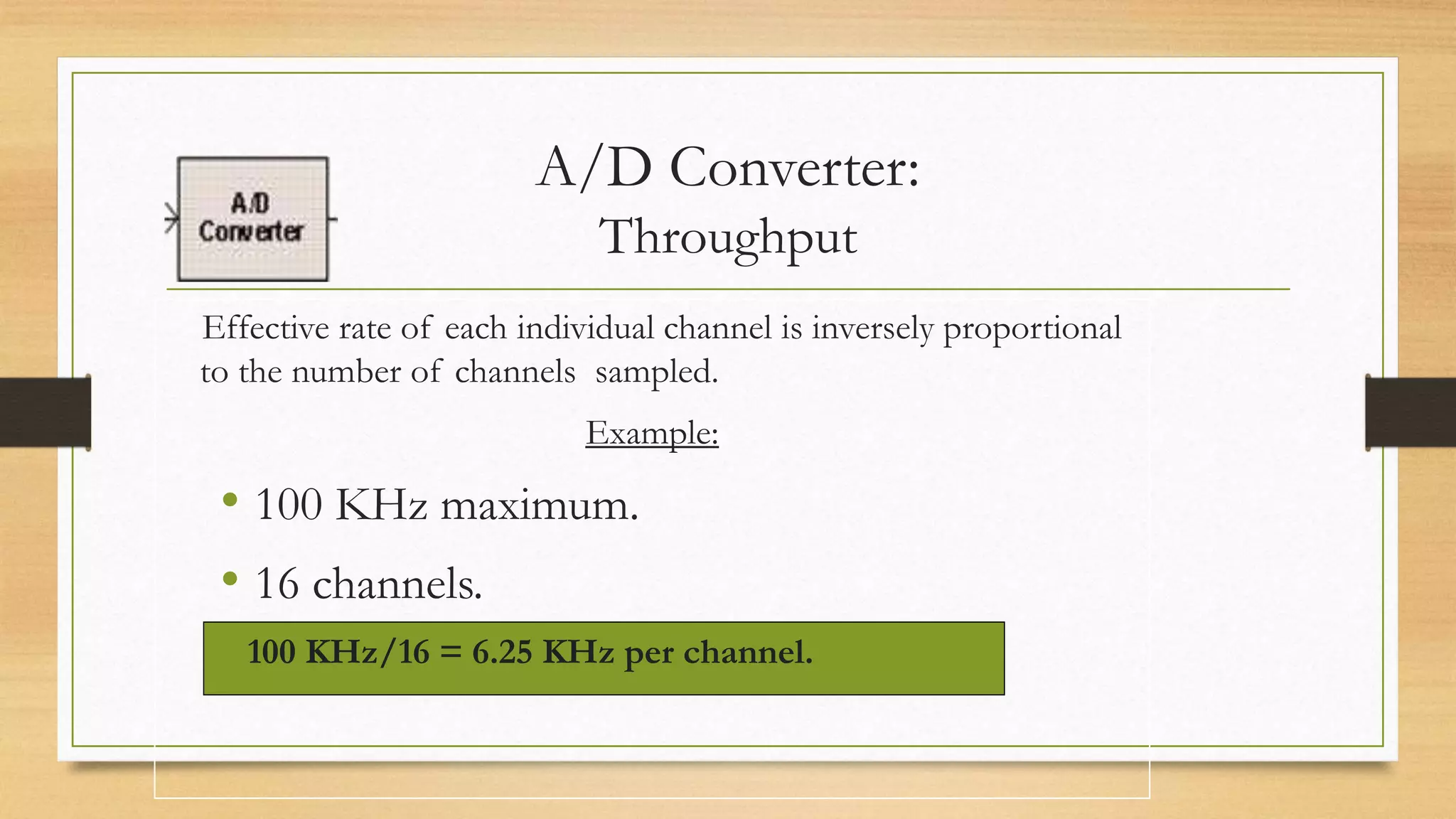

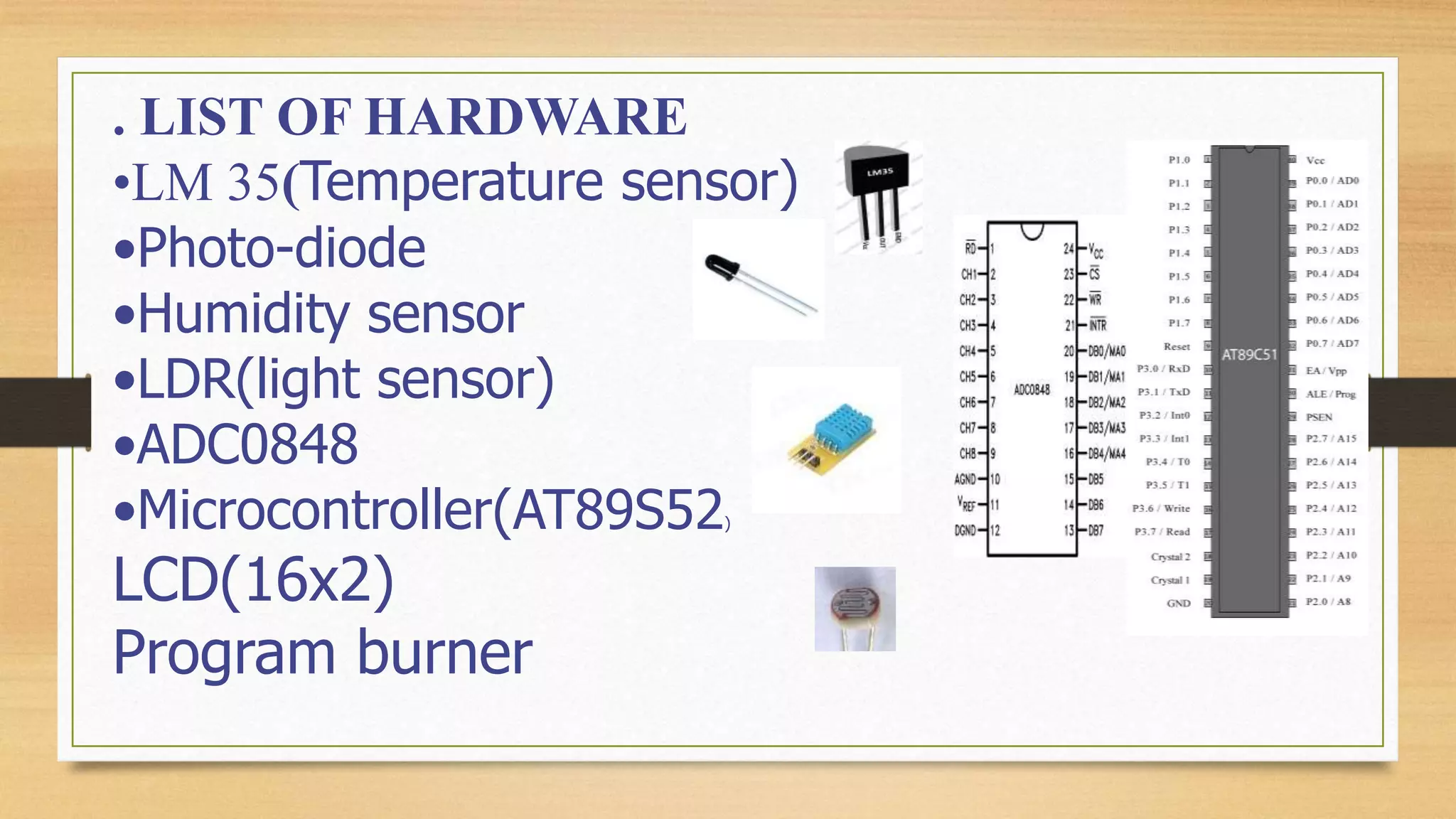

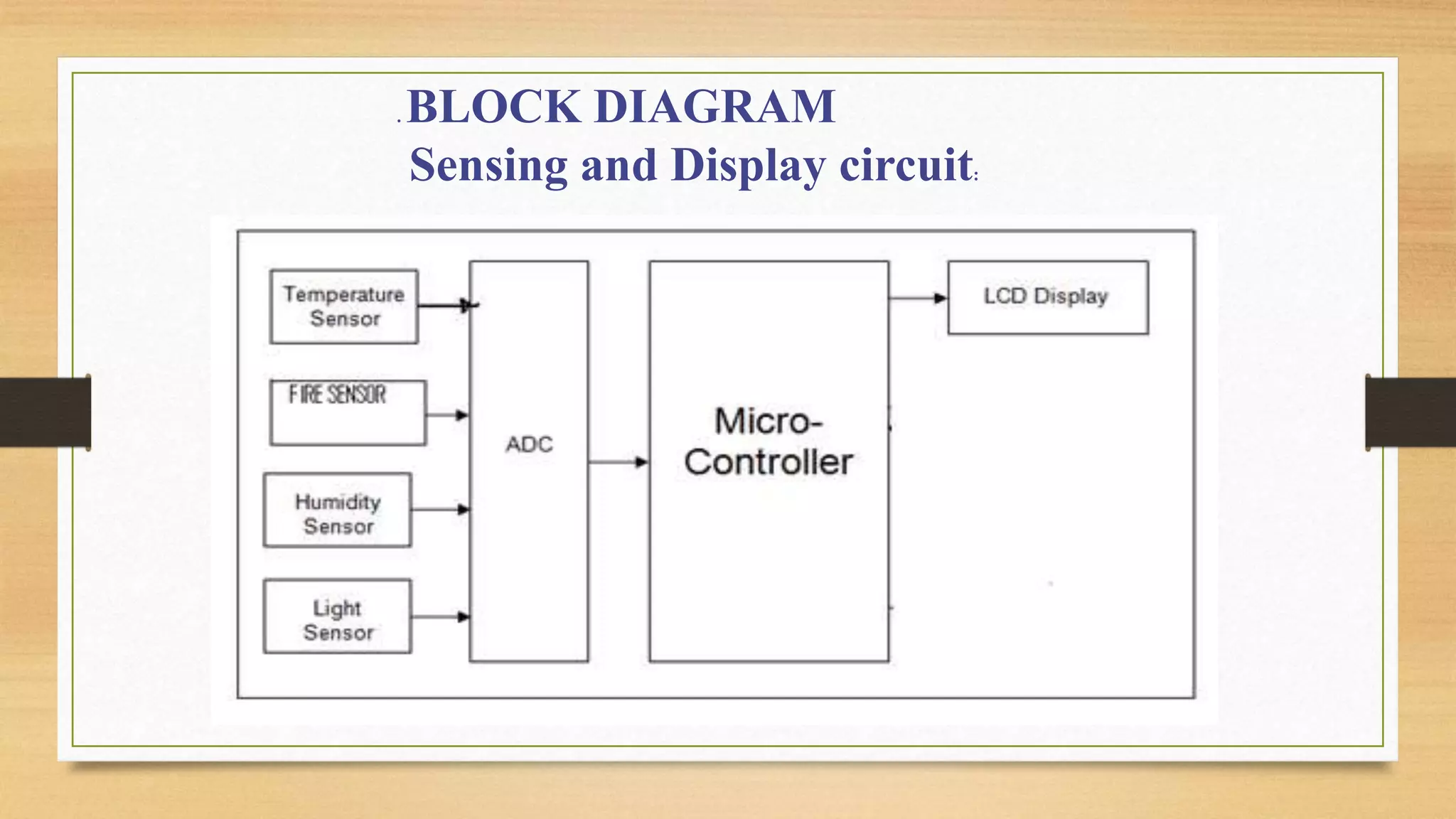

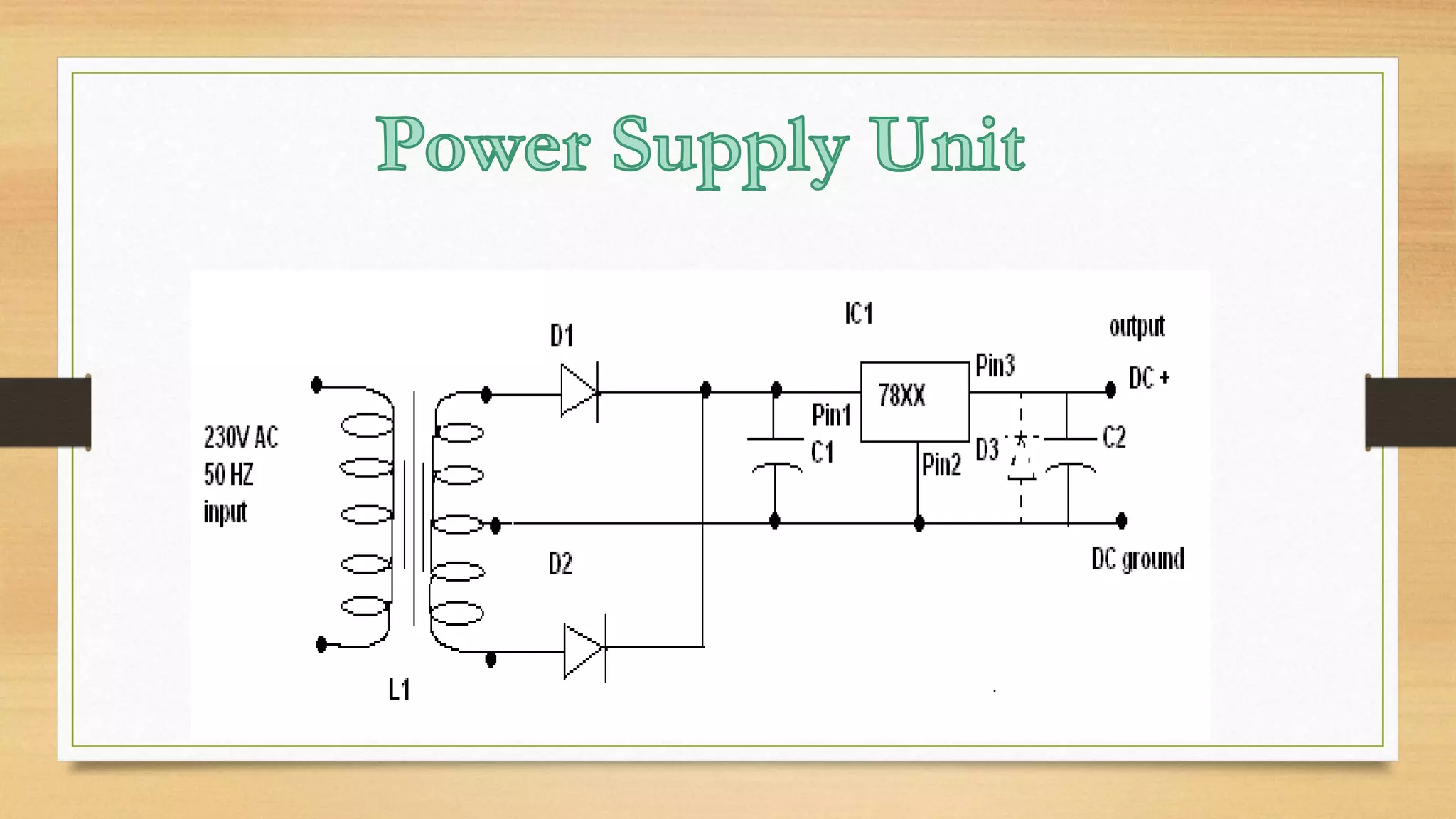

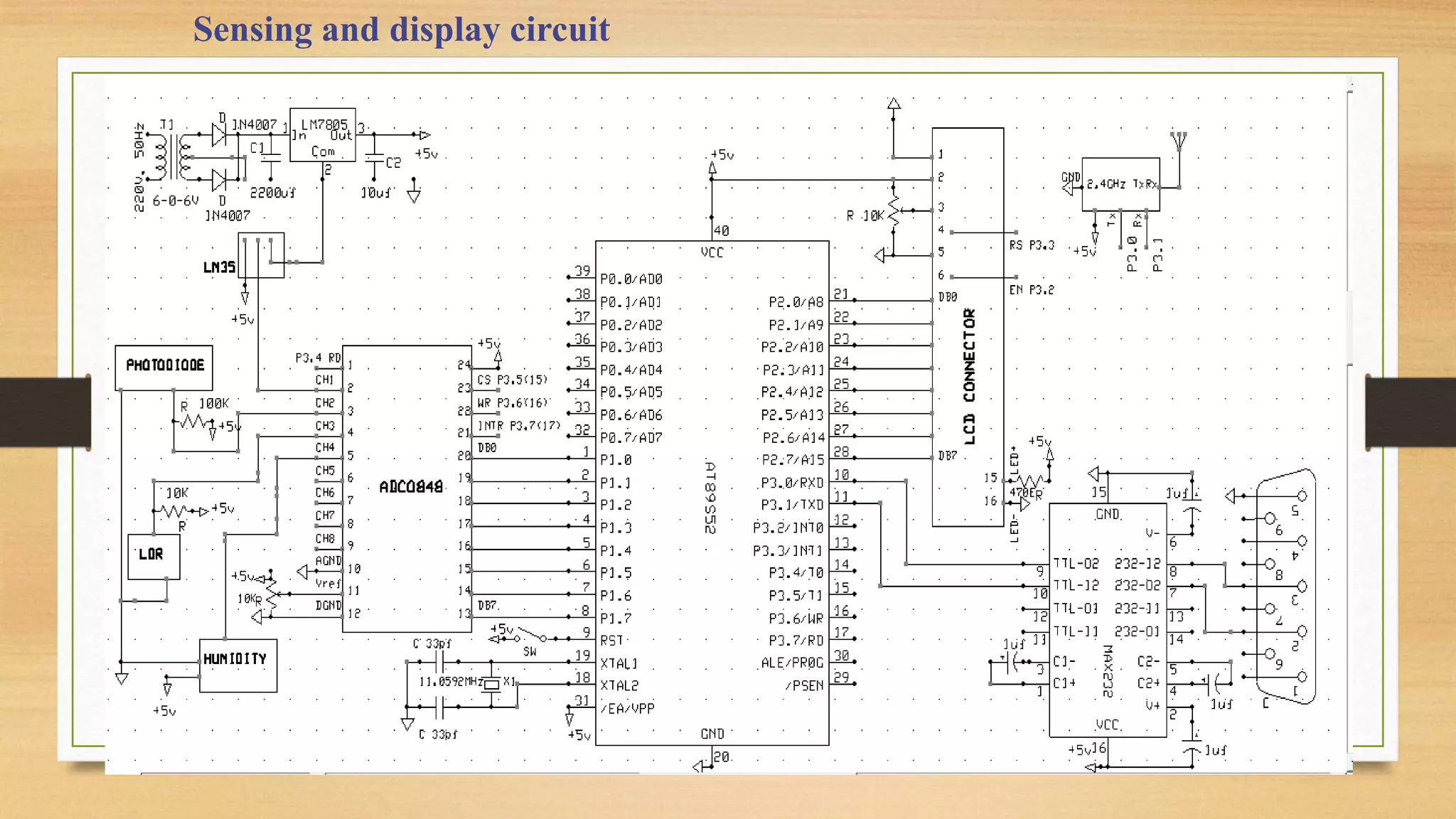

The document discusses an Instant Fire Detection and Suppression System (IFDSS) that is used indigenously to detect and suppress fires inside tank crews. It describes the IFDSS's detection logic and three-phase process of detecting a fire within 50 ms, applying logic and control, and fully suppressing the fire within 150 ms. It also provides information about data acquisition systems, including their components, processes, block diagrams, signal conditioning, analog inputs, and considerations for designing a data acquisition system.