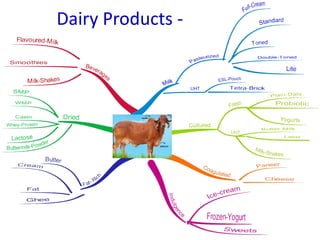

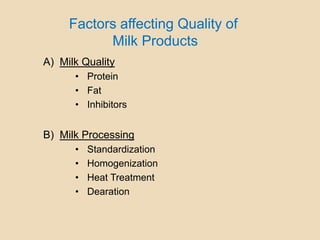

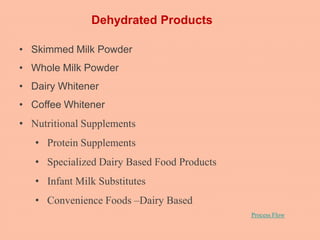

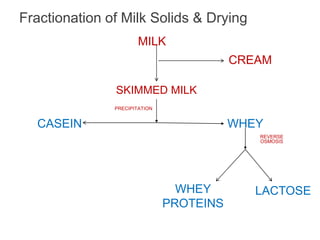

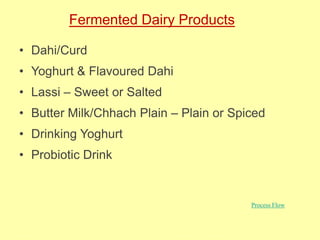

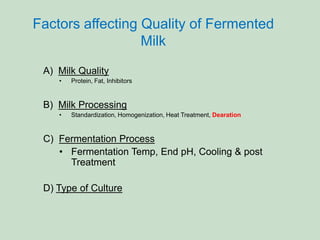

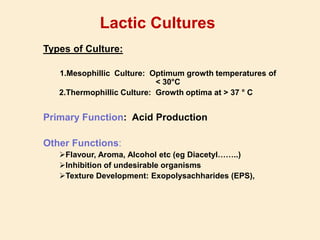

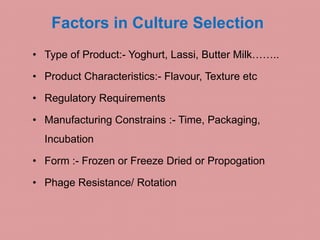

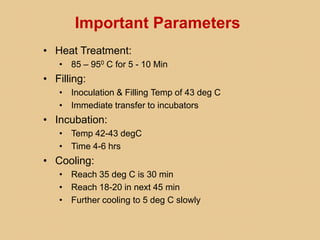

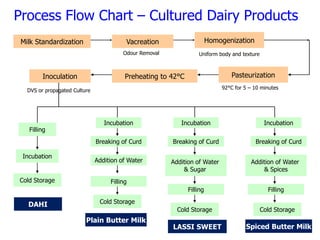

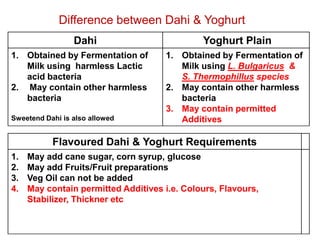

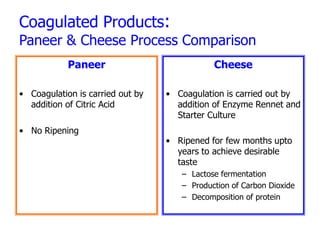

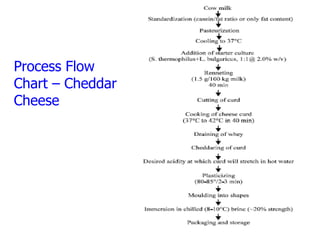

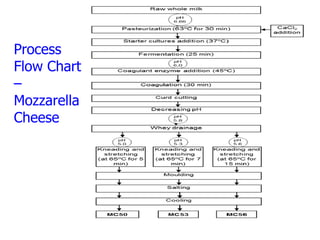

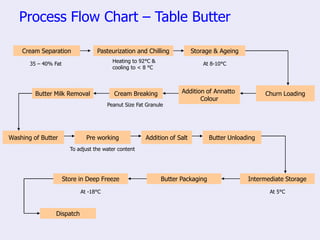

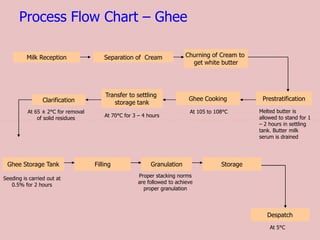

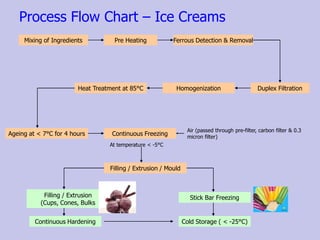

The document details the processing methods and quality factors affecting various dairy products, including milk, fermented products like yogurt, and coagulated products such as paneer and cheese. It outlines critical steps in dairy processing, including standardization, homogenization, and pasteurization, along with fermentation parameters and differences between products like dahi and yogurt. Additionally, it provides flow charts and specifications for processing cheddar cheese, mozzarella, butter, ghee, ice cream, and flavored milk.