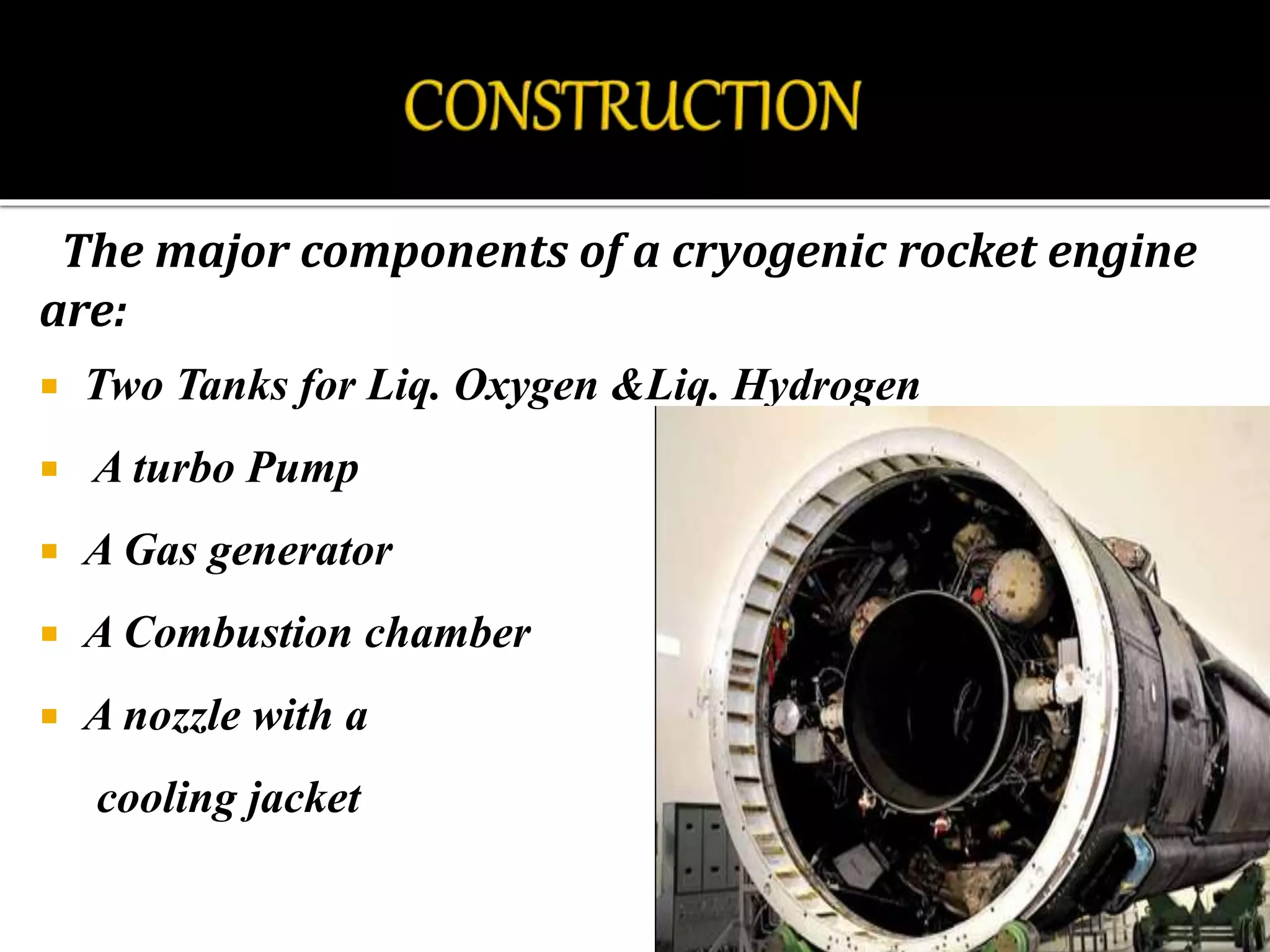

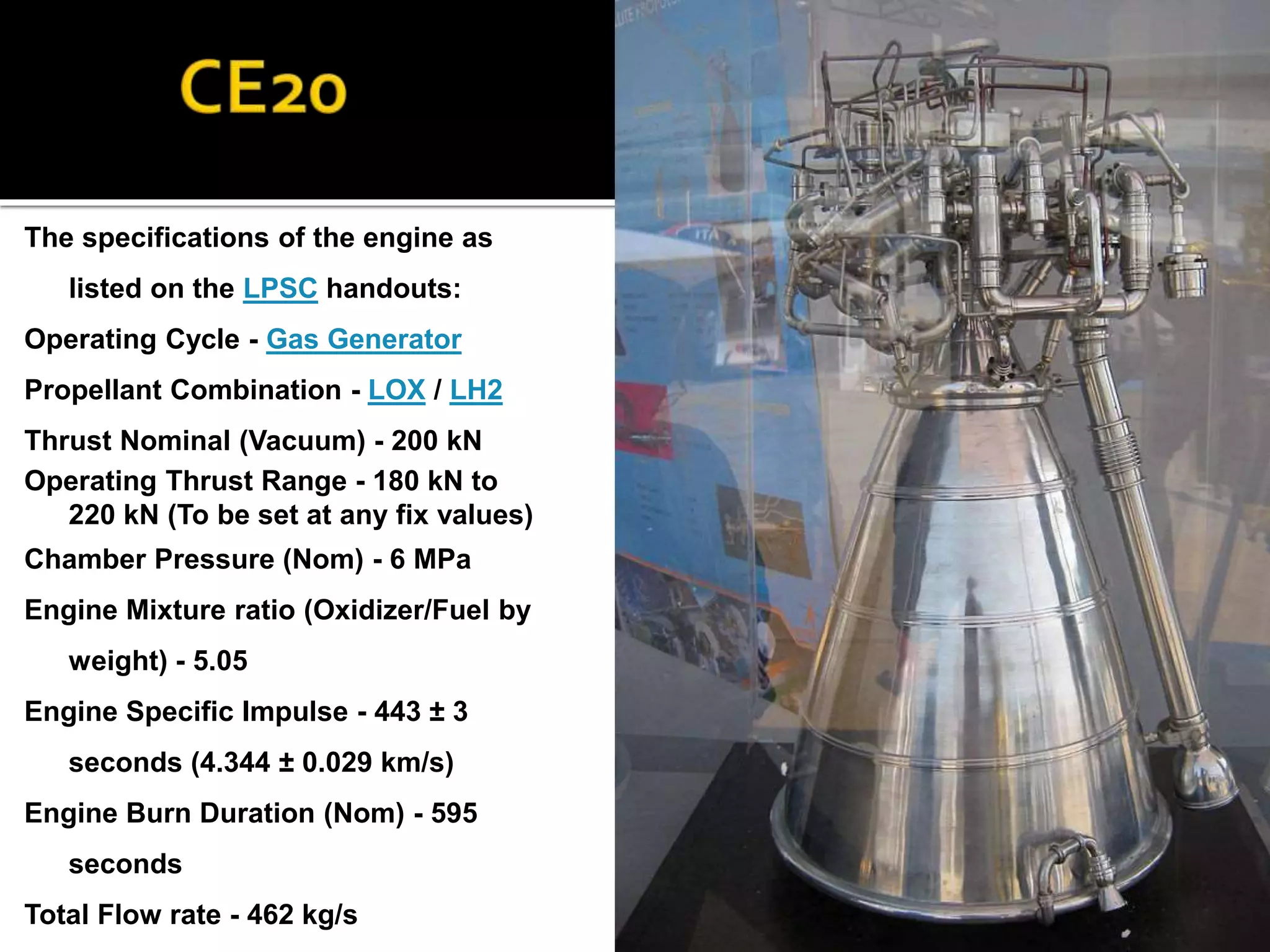

Cryogenics is the study of materials at very low temperatures below -150°C. Cryogenic rocket engines use cryogenic fuels like liquid oxygen and liquid hydrogen that must be stored at extremely cold temperatures to remain liquid. The first country to use a cryogenic engine was the USA in 1963, while Russia developed its own in 1983. India has successfully developed its own cryogenic upper stage powered by the CE-7.5 cryogenic engine. Cryogenic engines offer very high energy density and clean, economical propellants but also present challenges related to storage and handling of the cryogenic liquids.