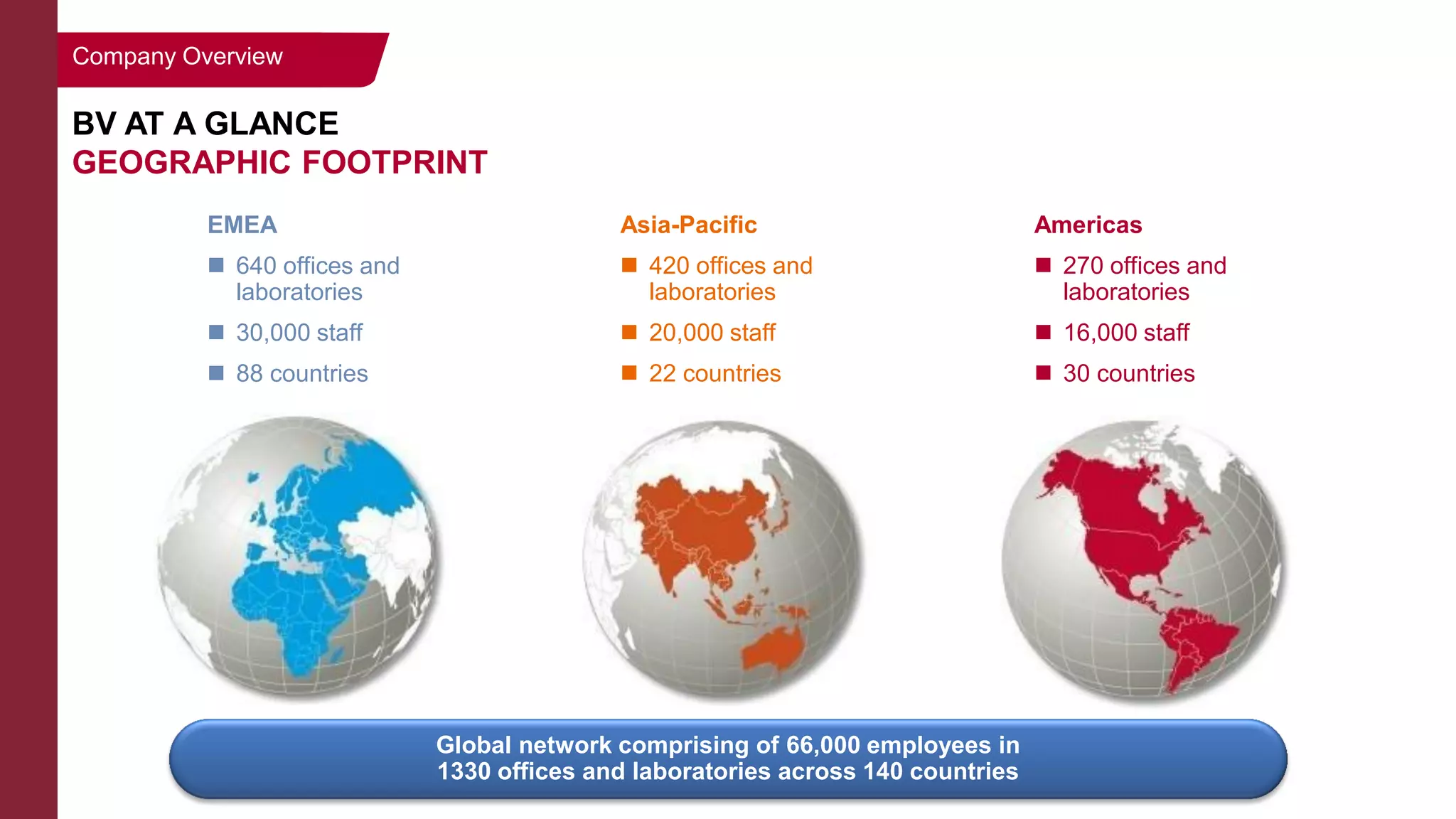

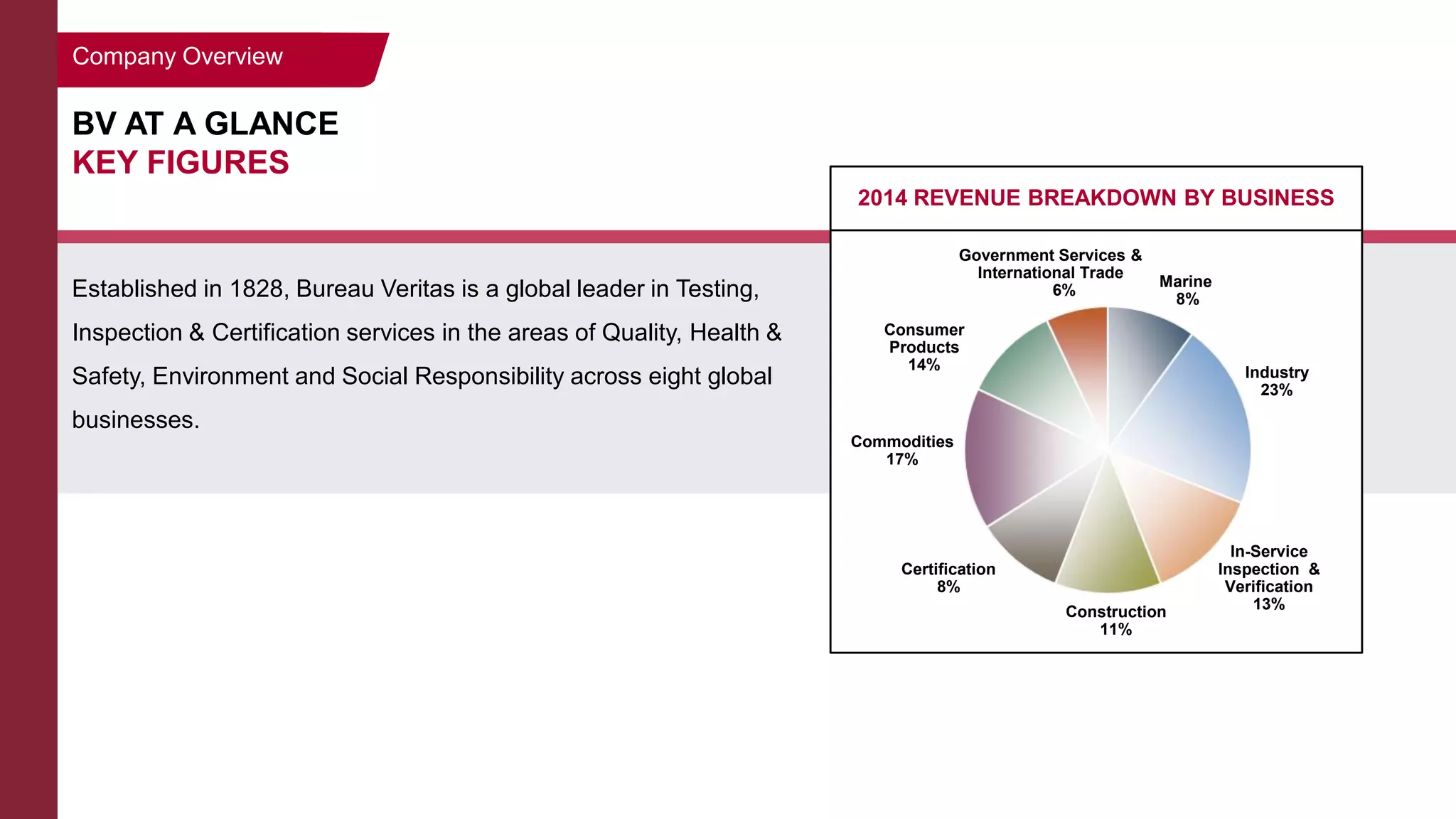

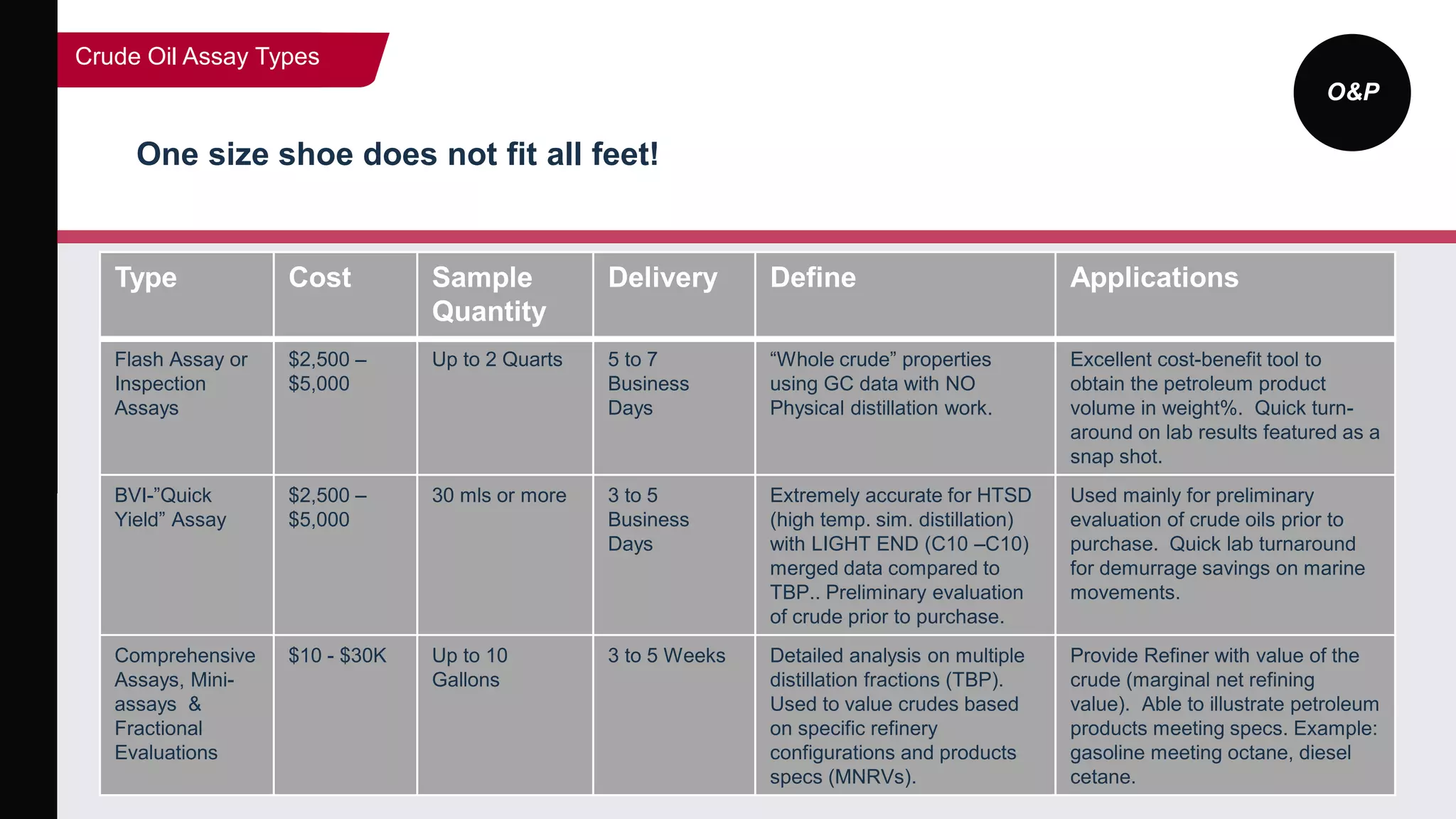

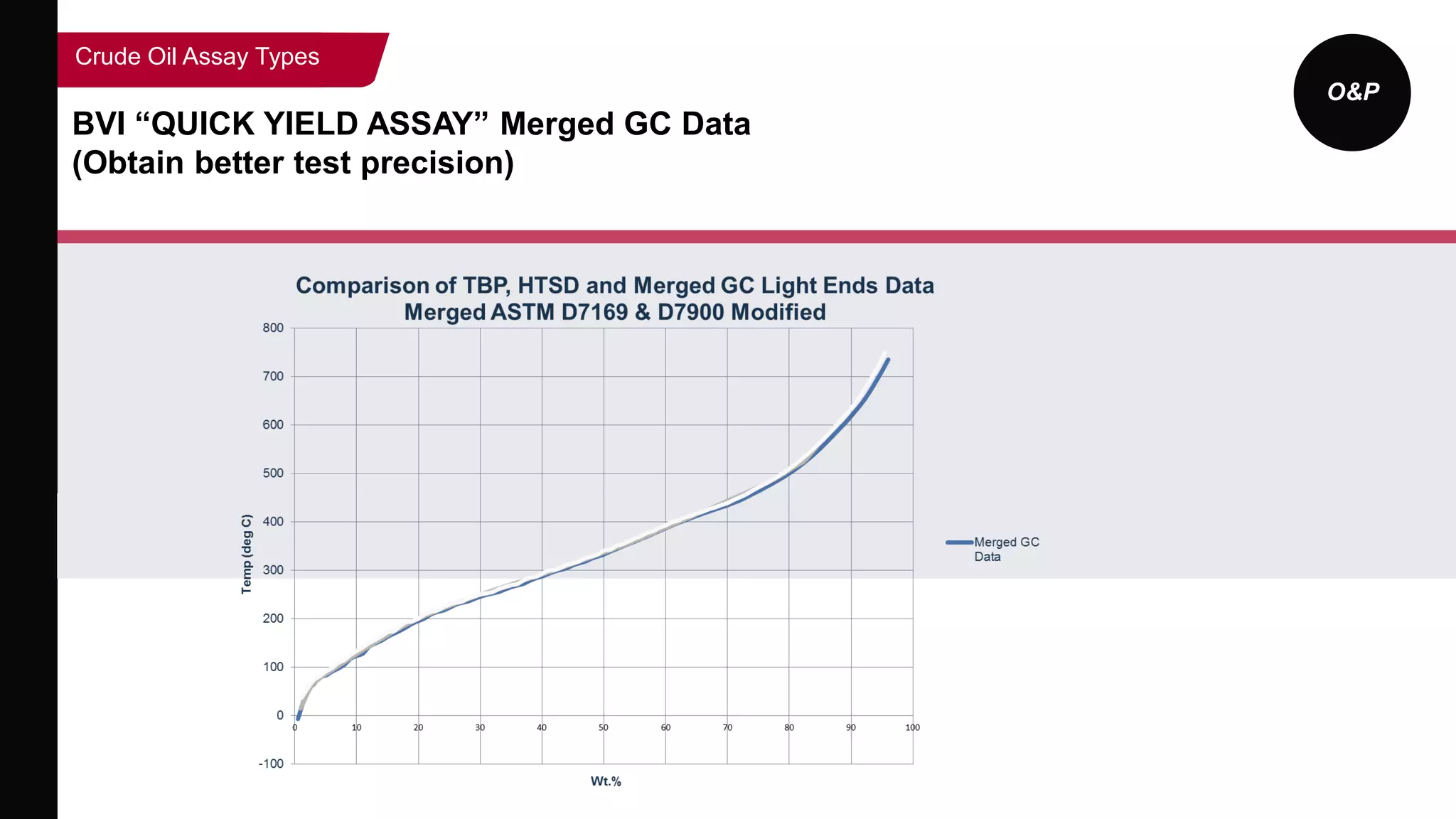

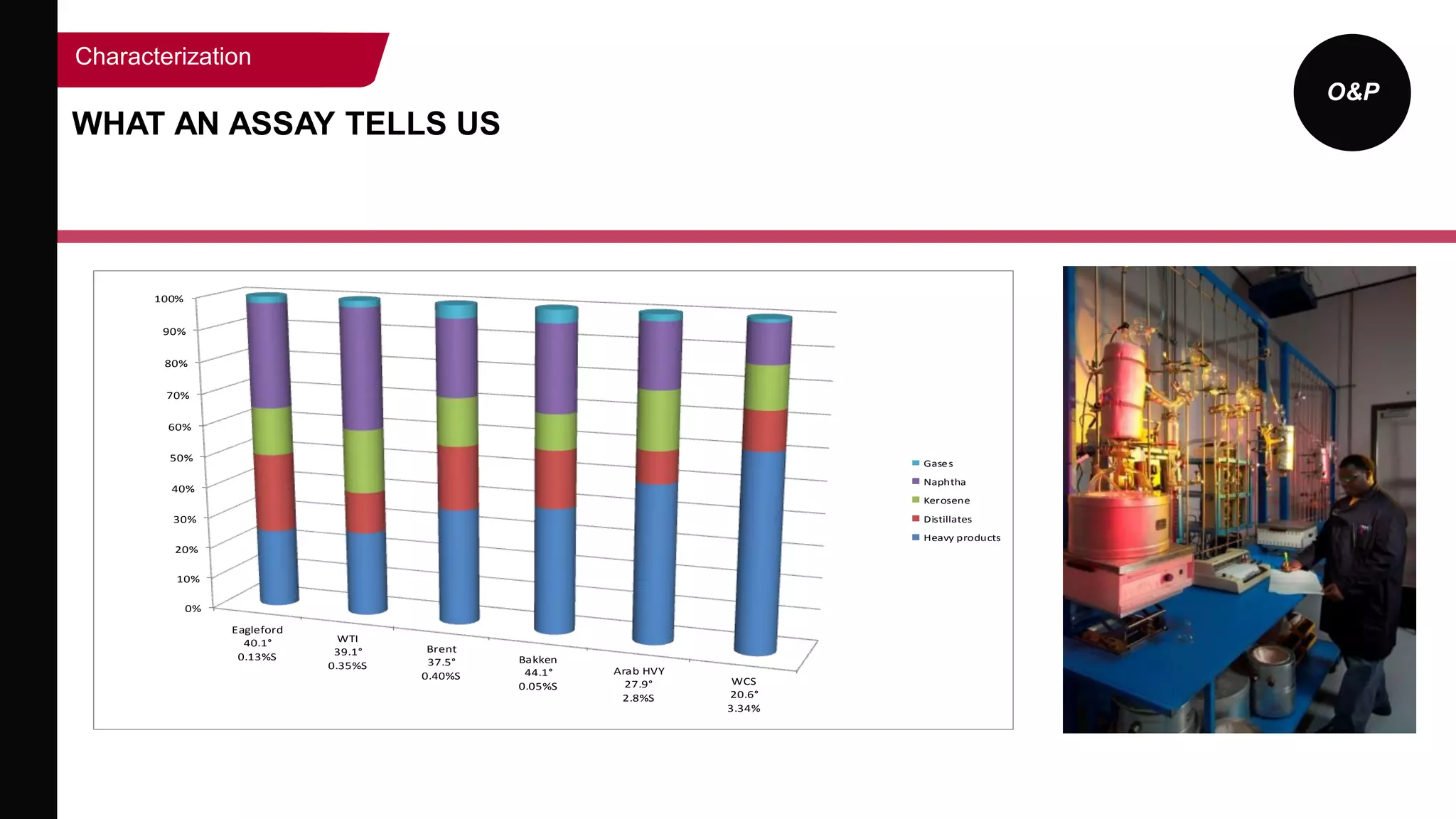

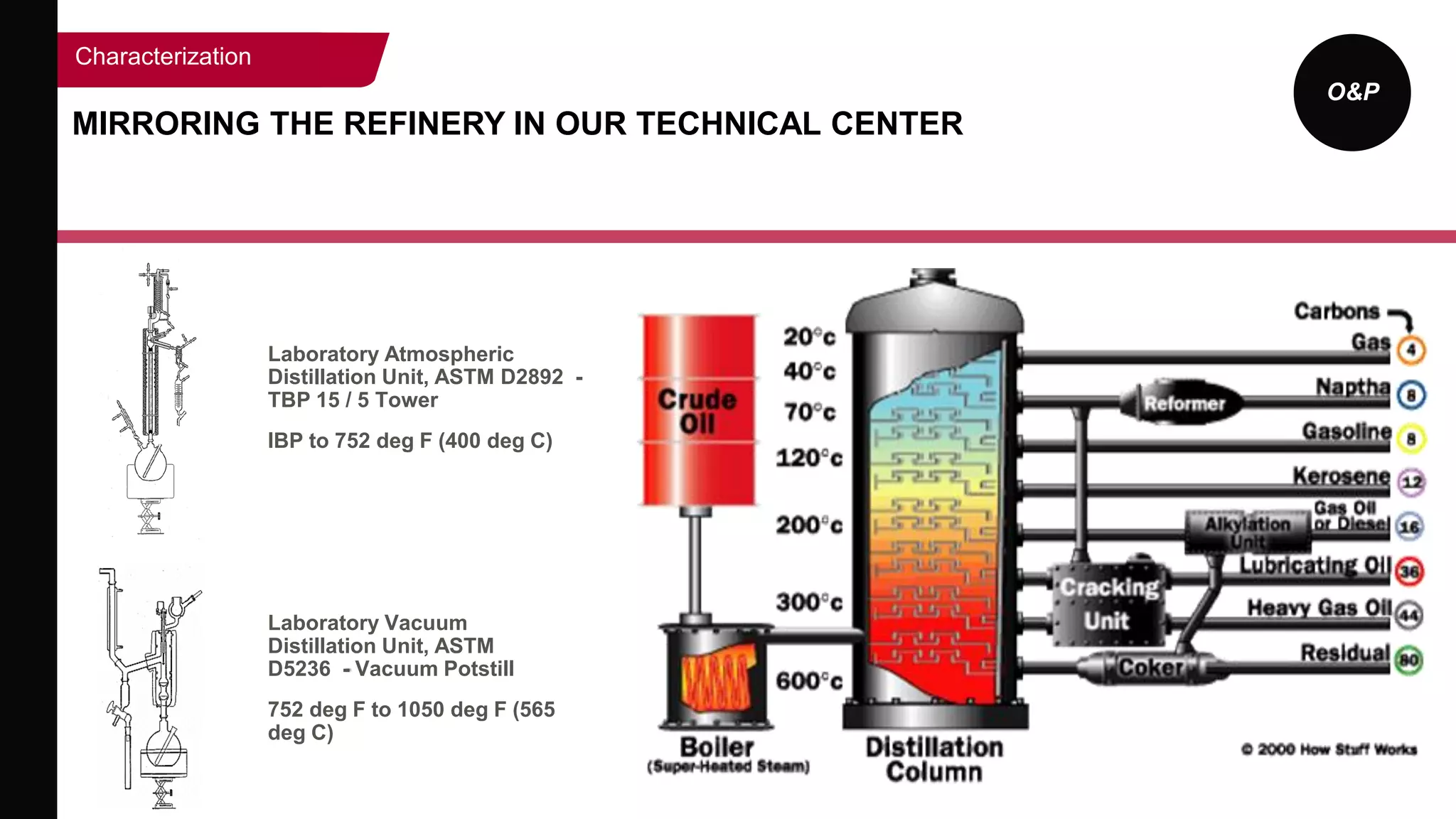

Bureau Veritas is a global leader in testing, inspection, and certification services with 66,000 employees across 1,330 offices in 140 countries. In 2014, its largest business lines by revenue were industry (23%), construction (11%), and commodities (17%). A crude oil assay is a chemical evaluation of a crude oil that provides detailed hydrocarbon analysis data to help producers, traders, and refiners assess each crude oil's properties and compatibility with refinery configurations. Assays can range from quick flash assays costing $2,500-$5,000 using gas chromatography to analyze whole crude properties, to comprehensive assays costing $10,000-$30,000 involving distillation and over 150 tests on fractions to determine a