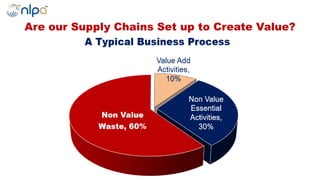

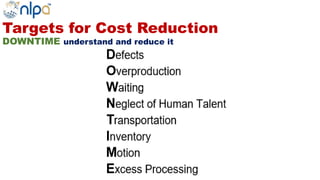

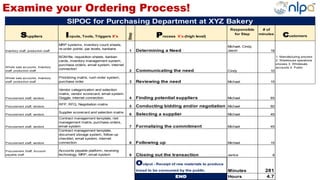

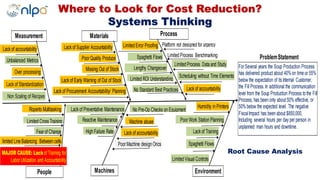

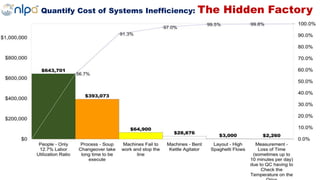

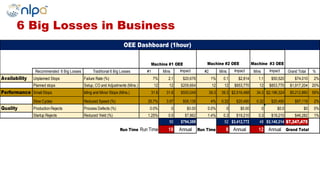

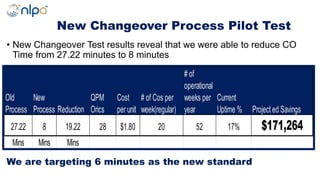

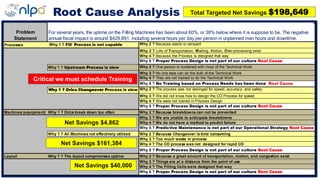

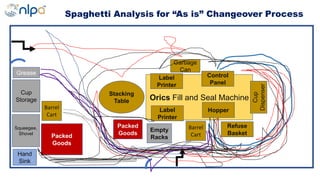

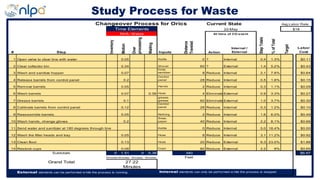

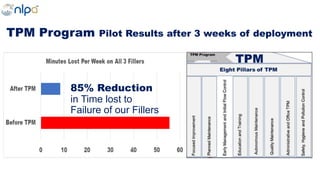

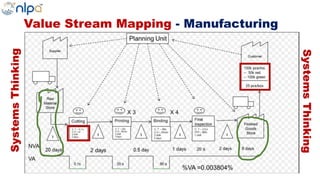

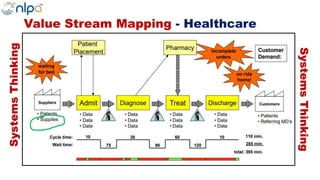

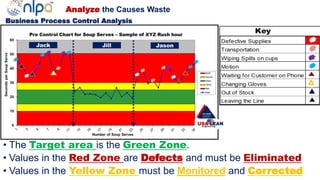

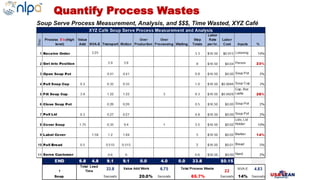

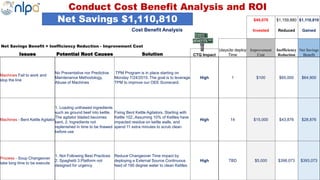

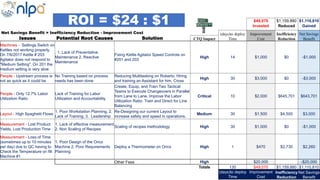

The webinar, led by David Millington, focuses on identifying non-value-added waste in supply chains and leveraging cost reduction strategies beyond mere price reductions of raw materials. It emphasizes collaboration, effective communication, and continuous improvement in supply chain processes to achieve substantial cost reductions. The document also includes a detailed analysis of potential cost-saving measures through process improvements, root cause analysis, and the implementation of better training and systems thinking in production environments.