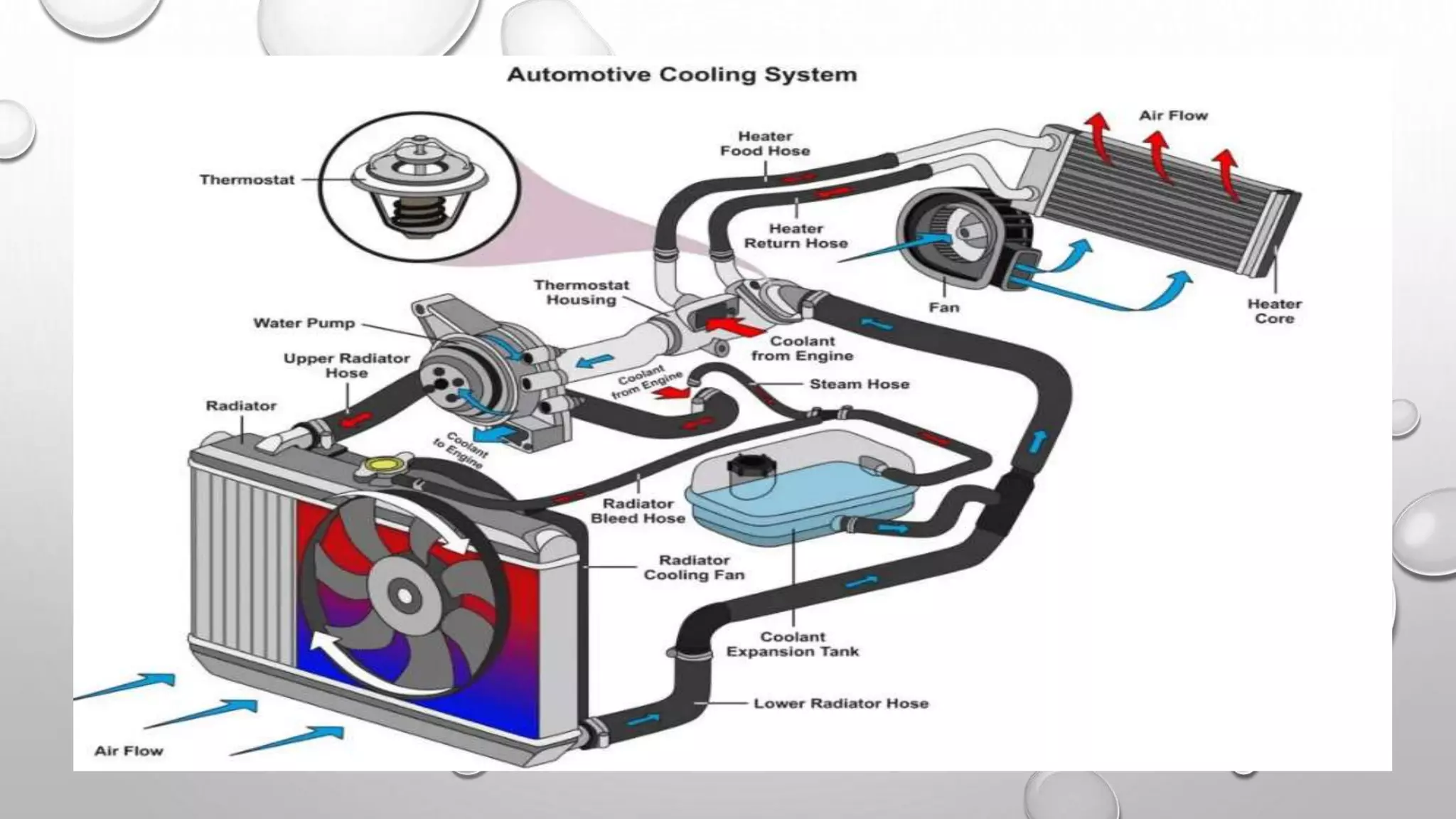

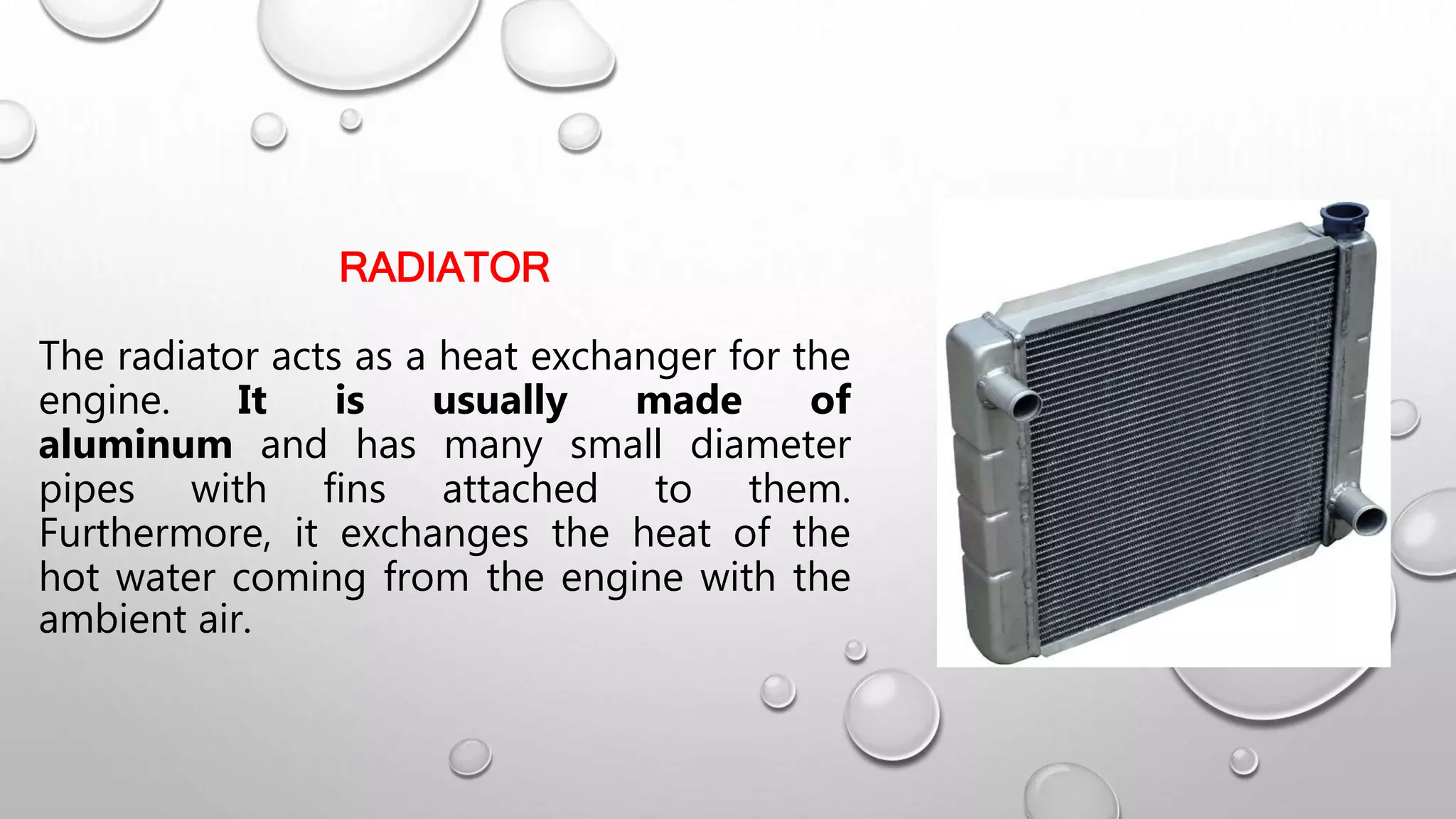

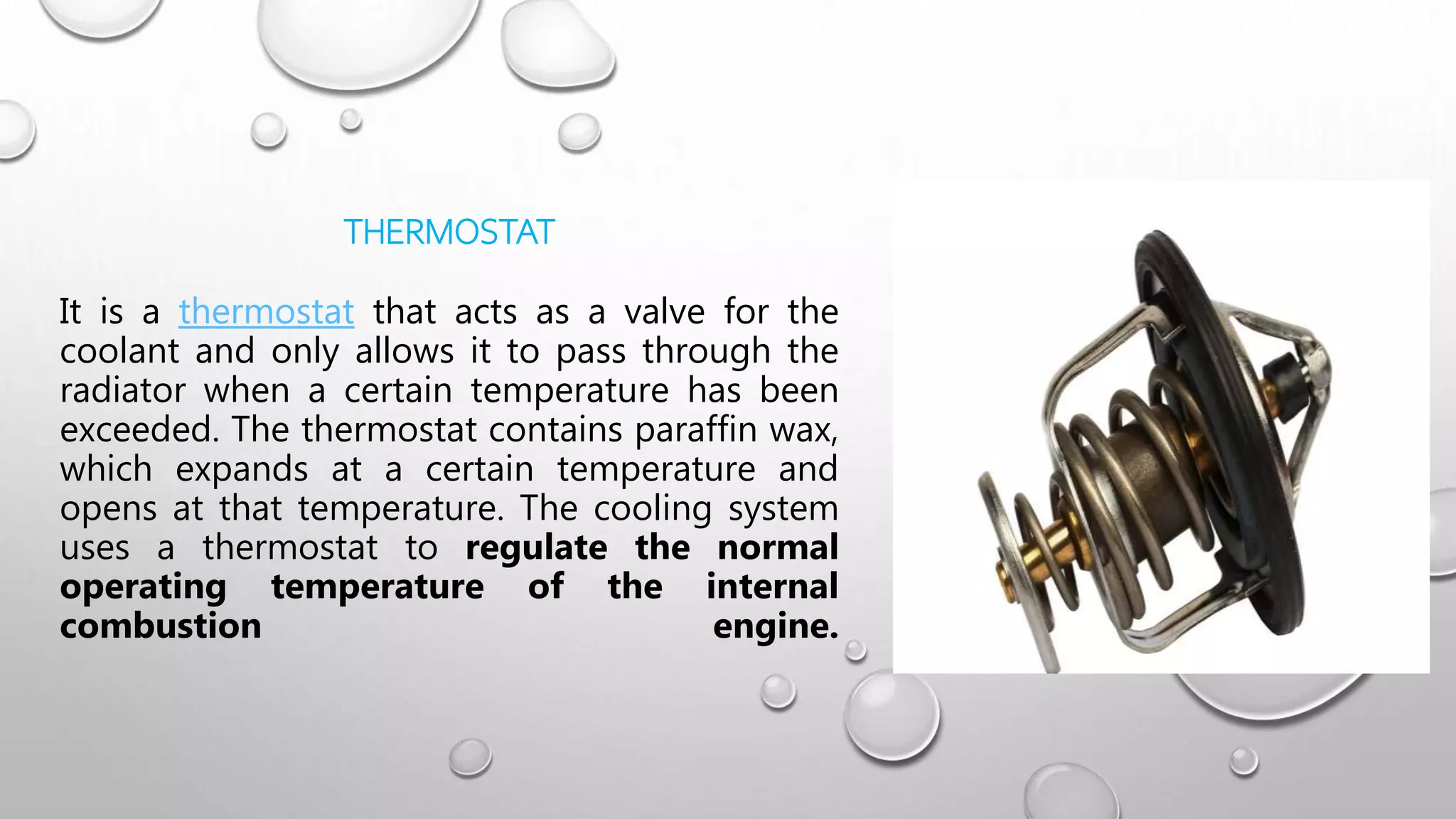

The presentation discusses the cooling system in diesel engines, explaining its significance in maintaining optimal engine temperature to prevent overheating and ensure efficiency. It distinguishes between liquid (indirect) and air (direct) cooling systems, detailing their mechanisms, advantages, and limitations. Key components such as the radiator, water pump, thermostat, and hoses are highlighted along with their functions in heat exchange and coolant regulation.