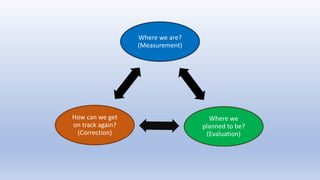

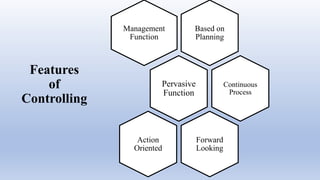

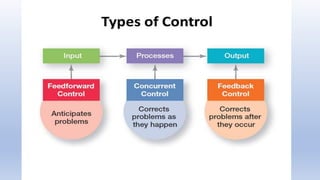

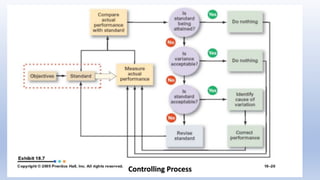

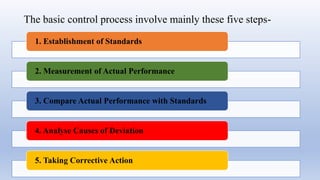

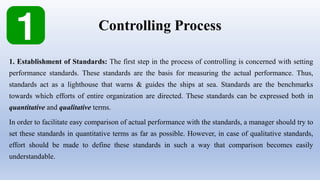

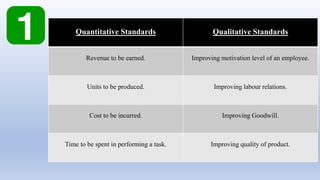

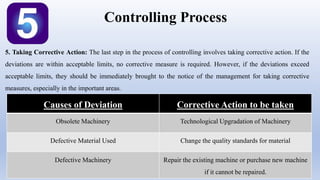

This document discusses the process of controlling in management. It defines controlling as measuring performance against standards and taking corrective action when needed. The key steps in the controlling process are: 1) Establishing standards of measurement, 2) Measuring actual performance, 3) Comparing actual performance to standards, 4) Analyzing causes of deviation, and 5) Taking corrective action. The document also discusses different types of controls like feed-forward, concurrent, and feedback controls and prerequisites for an effective control system like being simple, objective, and flexible.