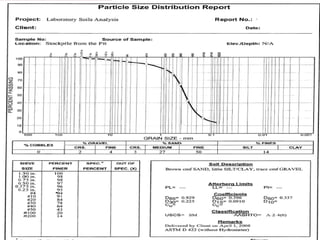

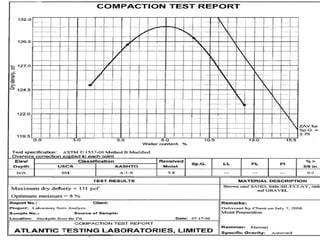

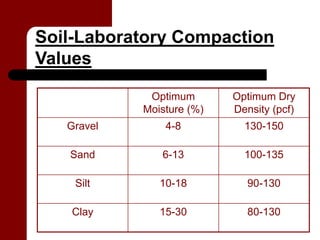

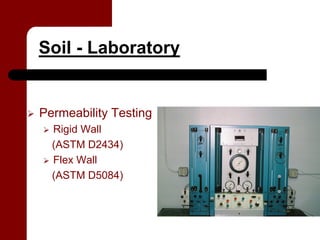

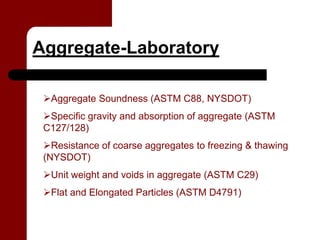

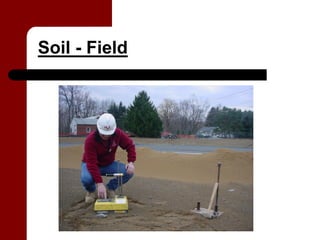

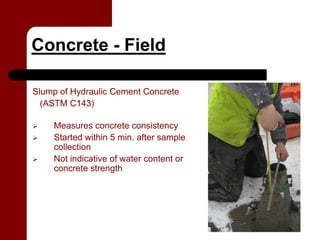

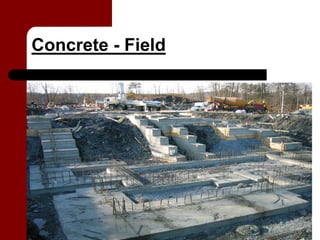

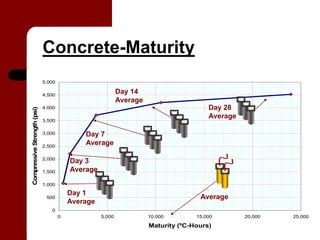

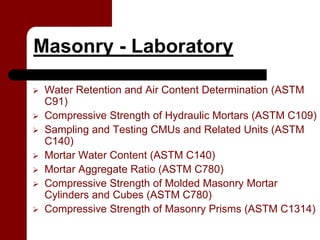

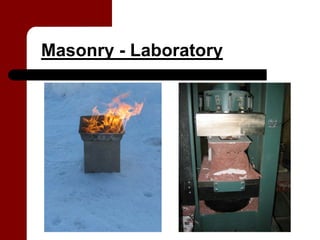

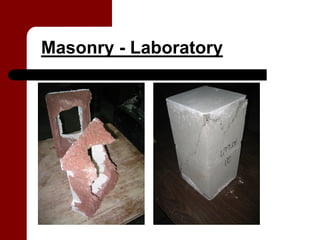

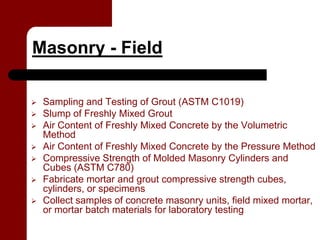

This document provides an overview of materials testing services for soil, aggregate, concrete, and masonry. It describes common laboratory and field tests for evaluating the properties and quality of construction materials, including tests for soil particle size and compaction, concrete slump and strength, and masonry compressive strength. The document emphasizes that materials testing should be performed by properly trained personnel according to standardized test methods and that test results should be reported in a timely manner.