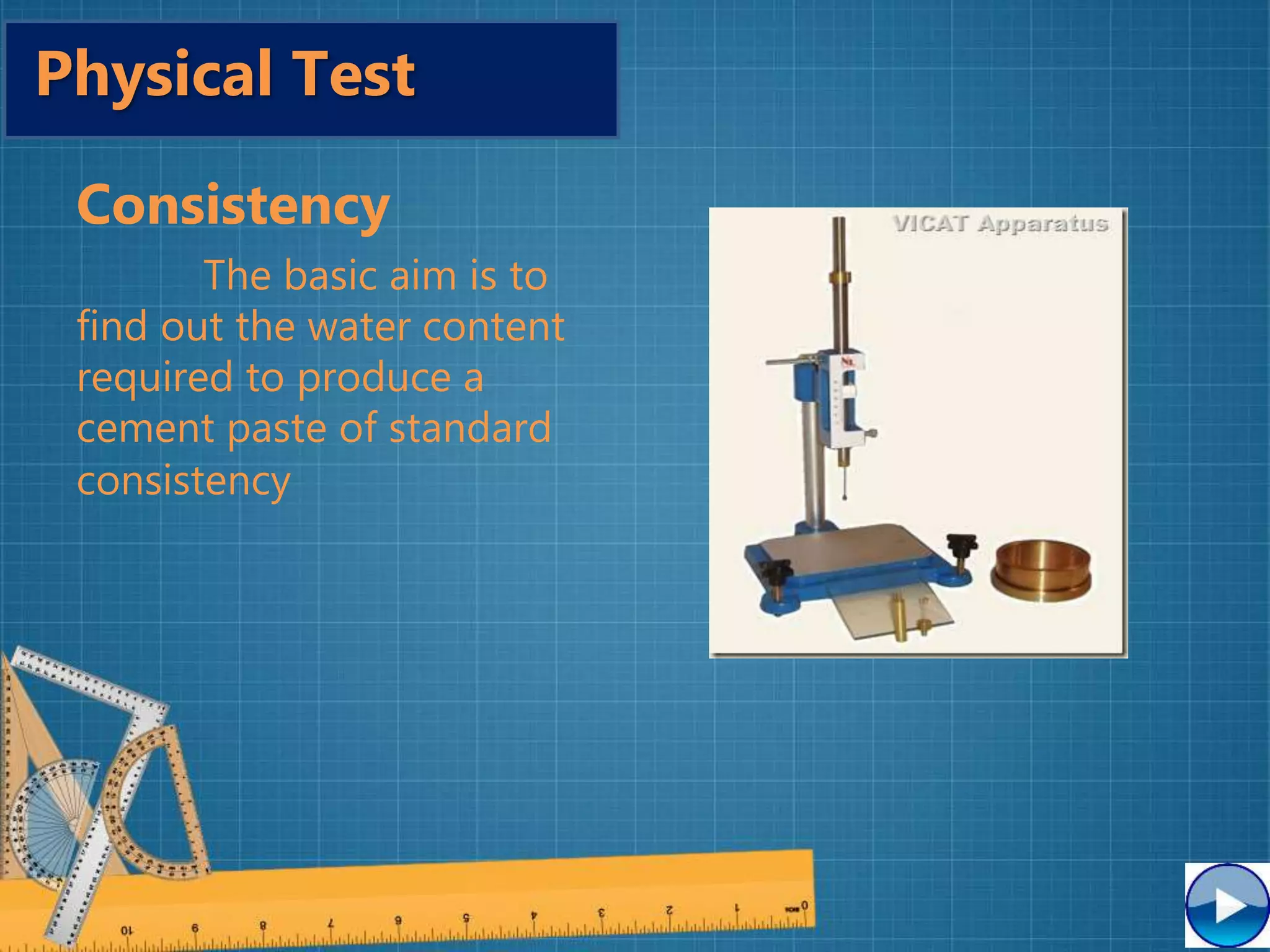

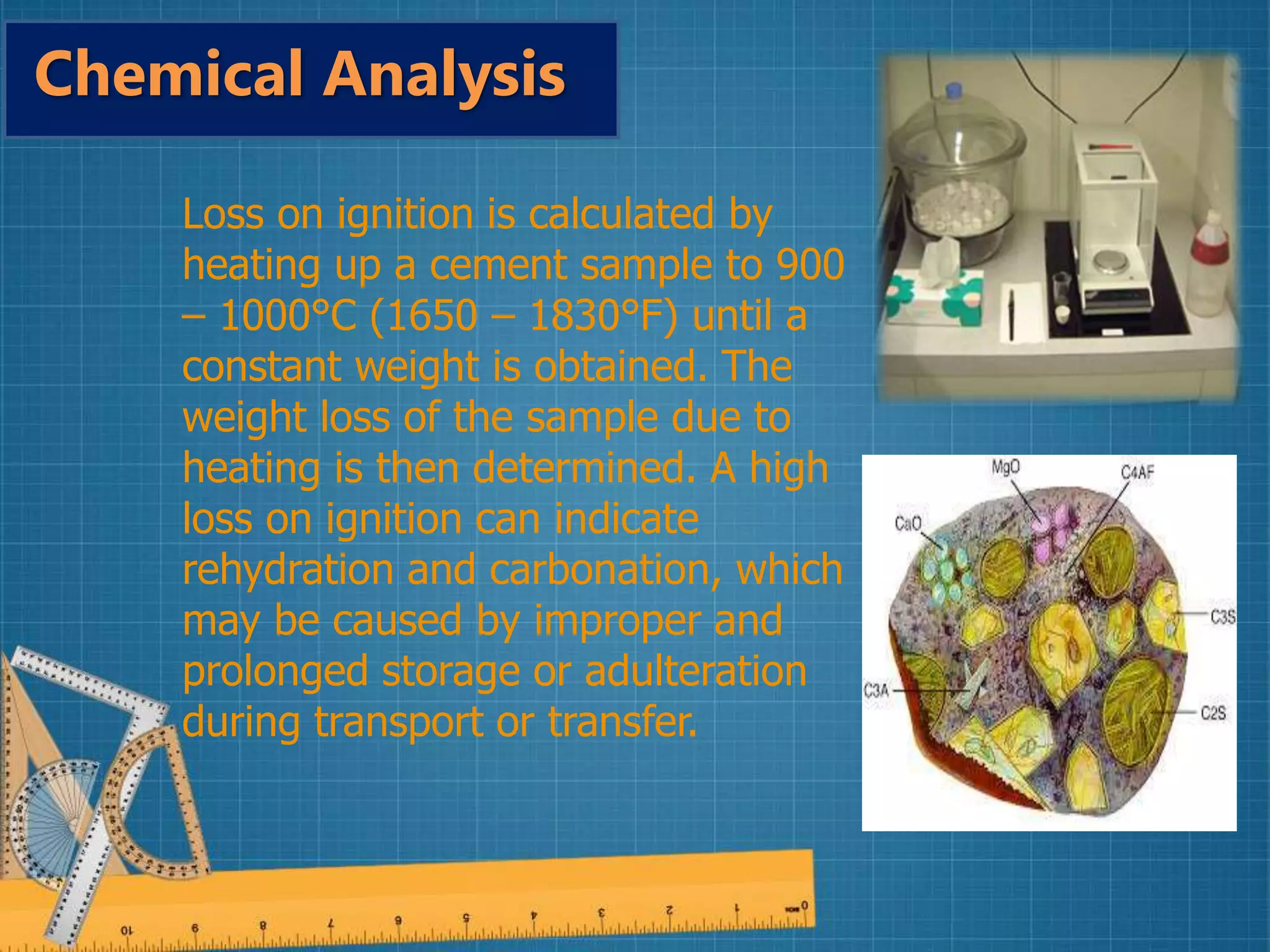

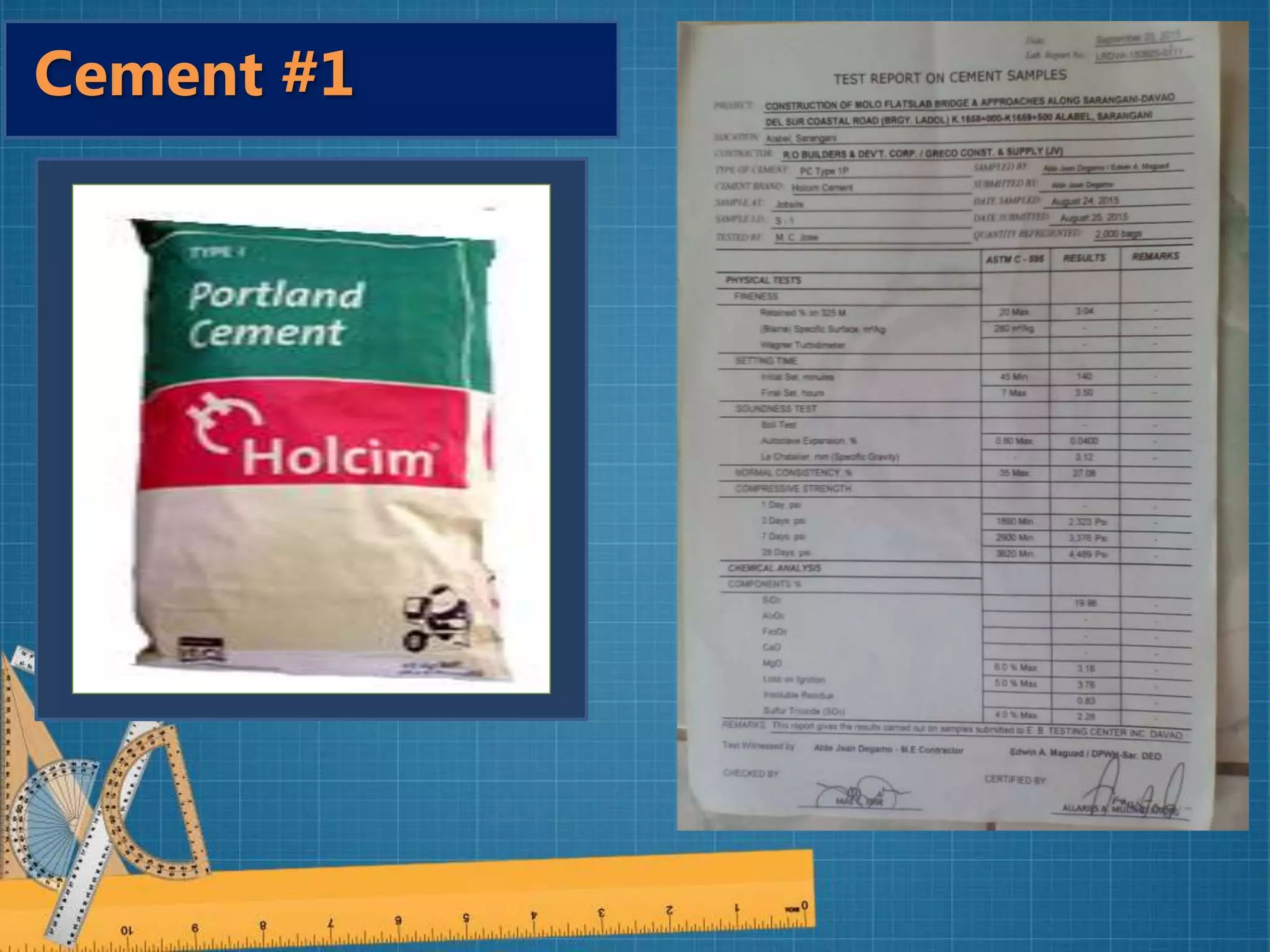

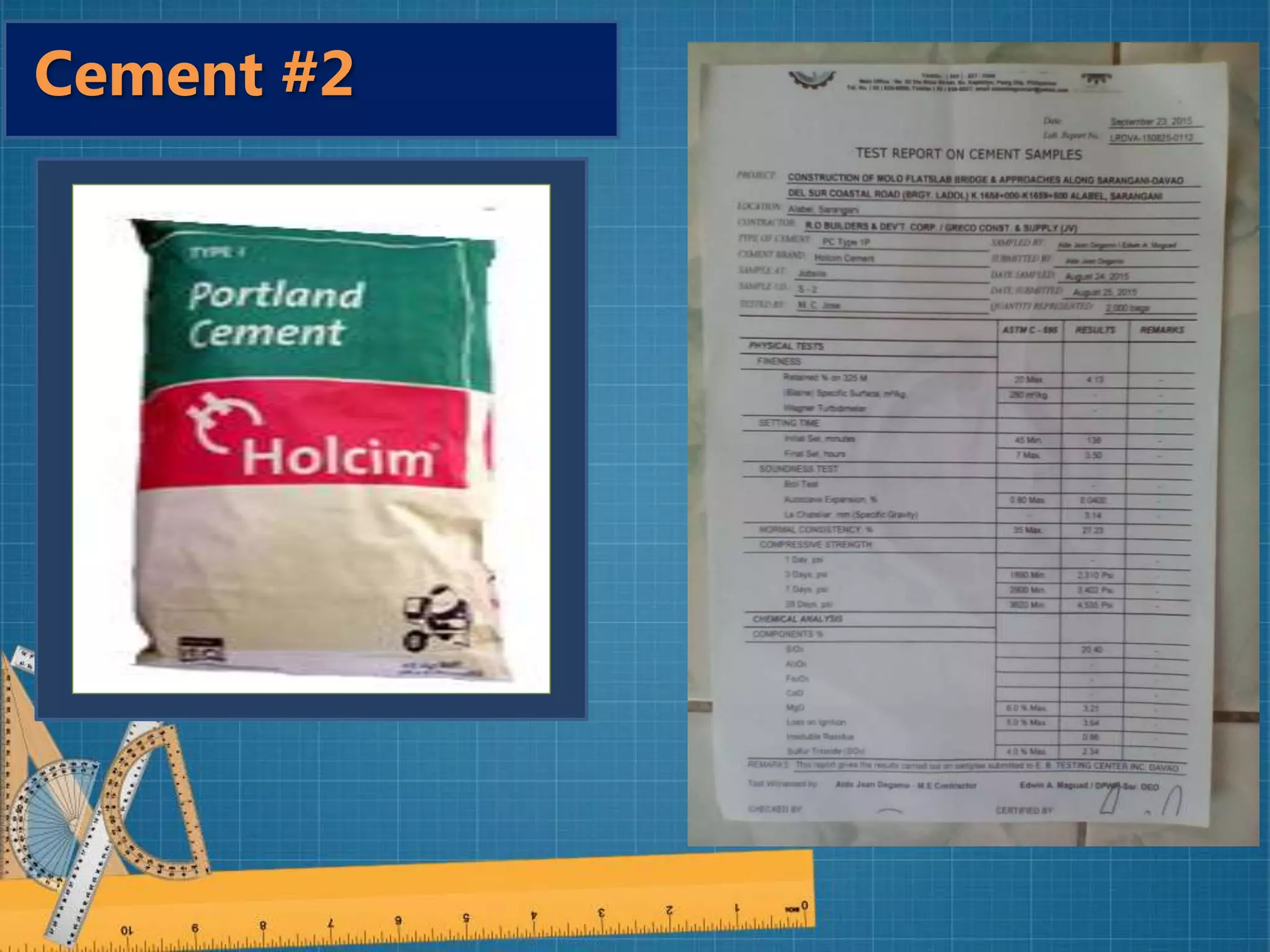

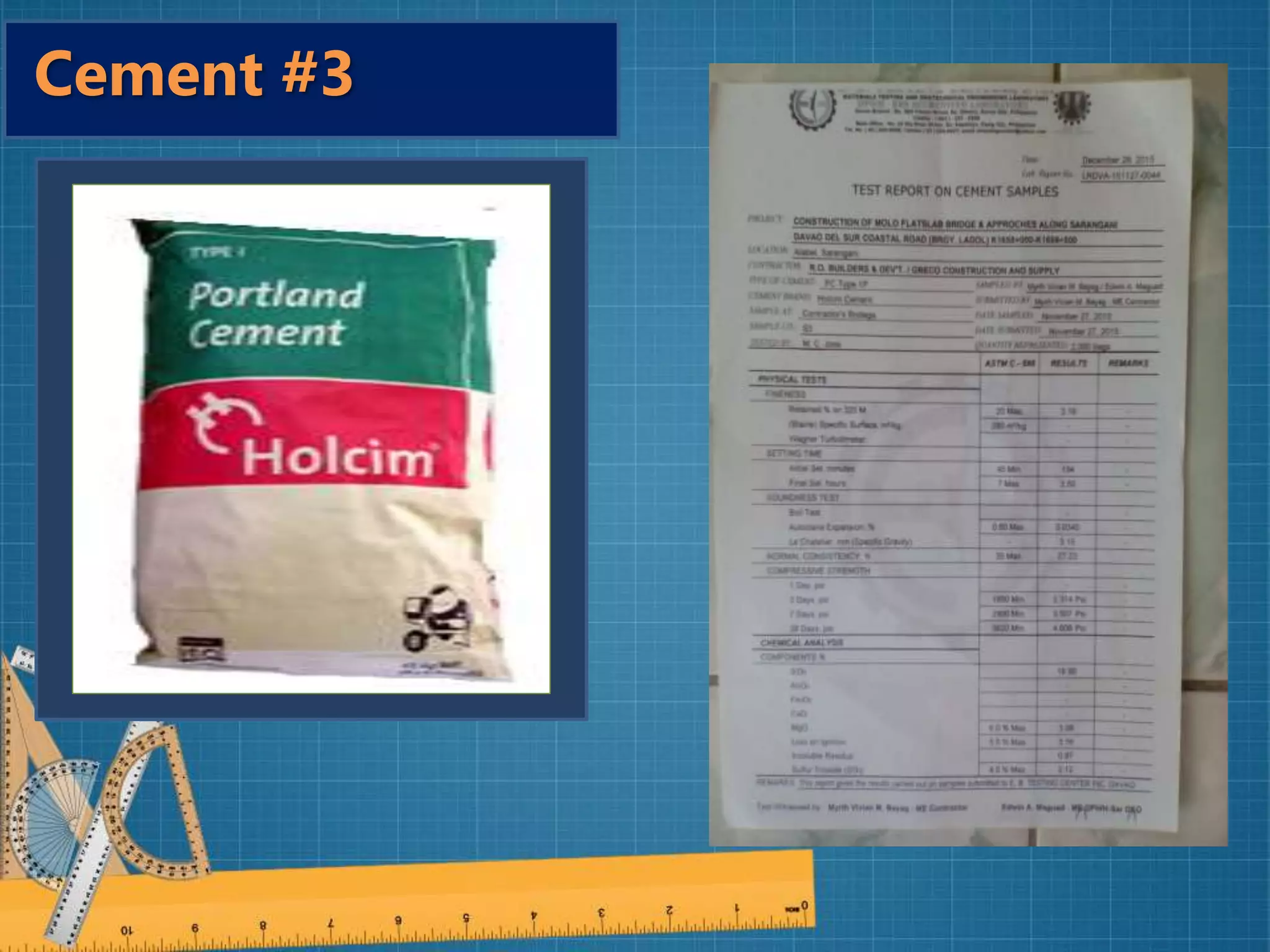

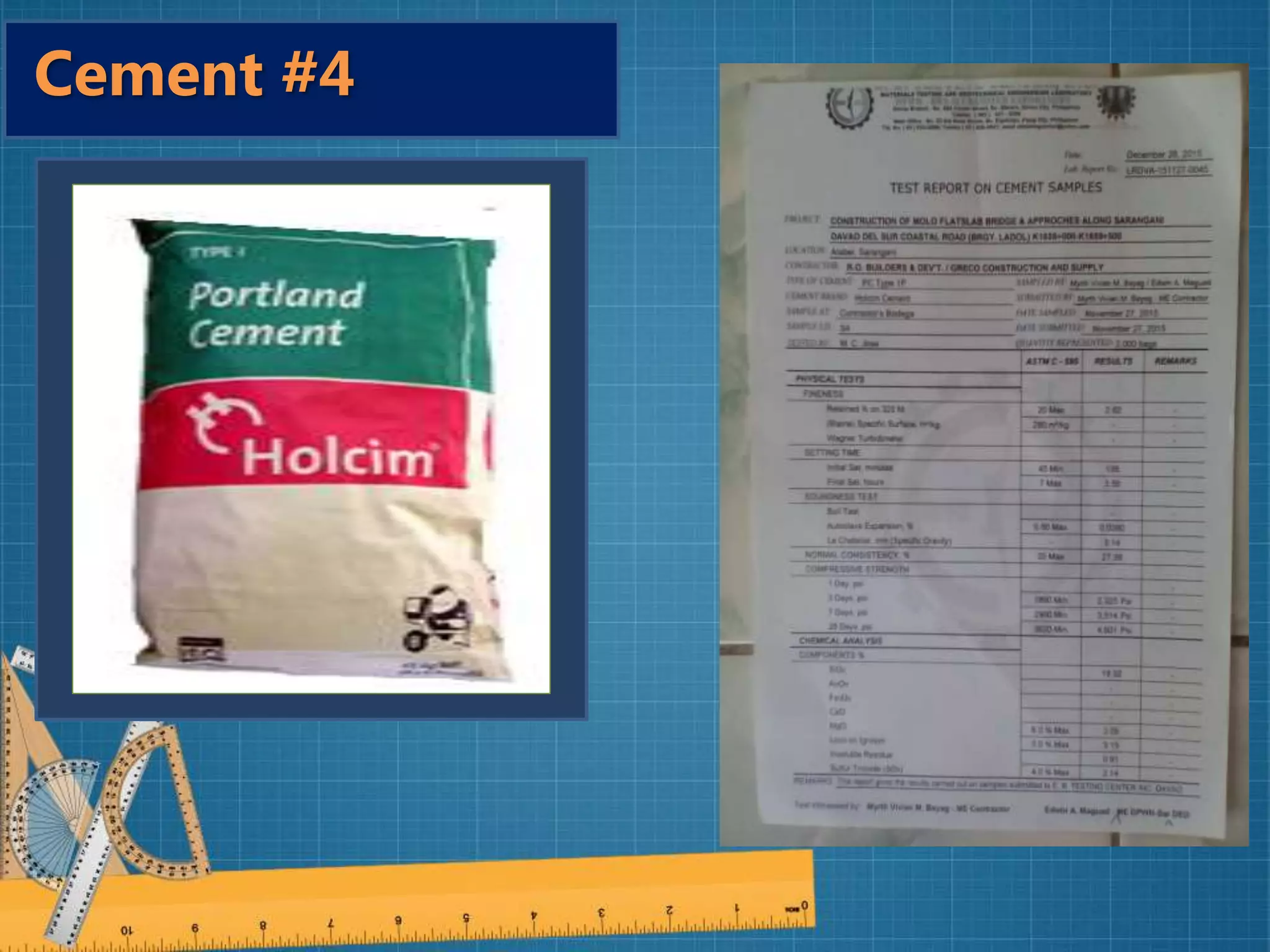

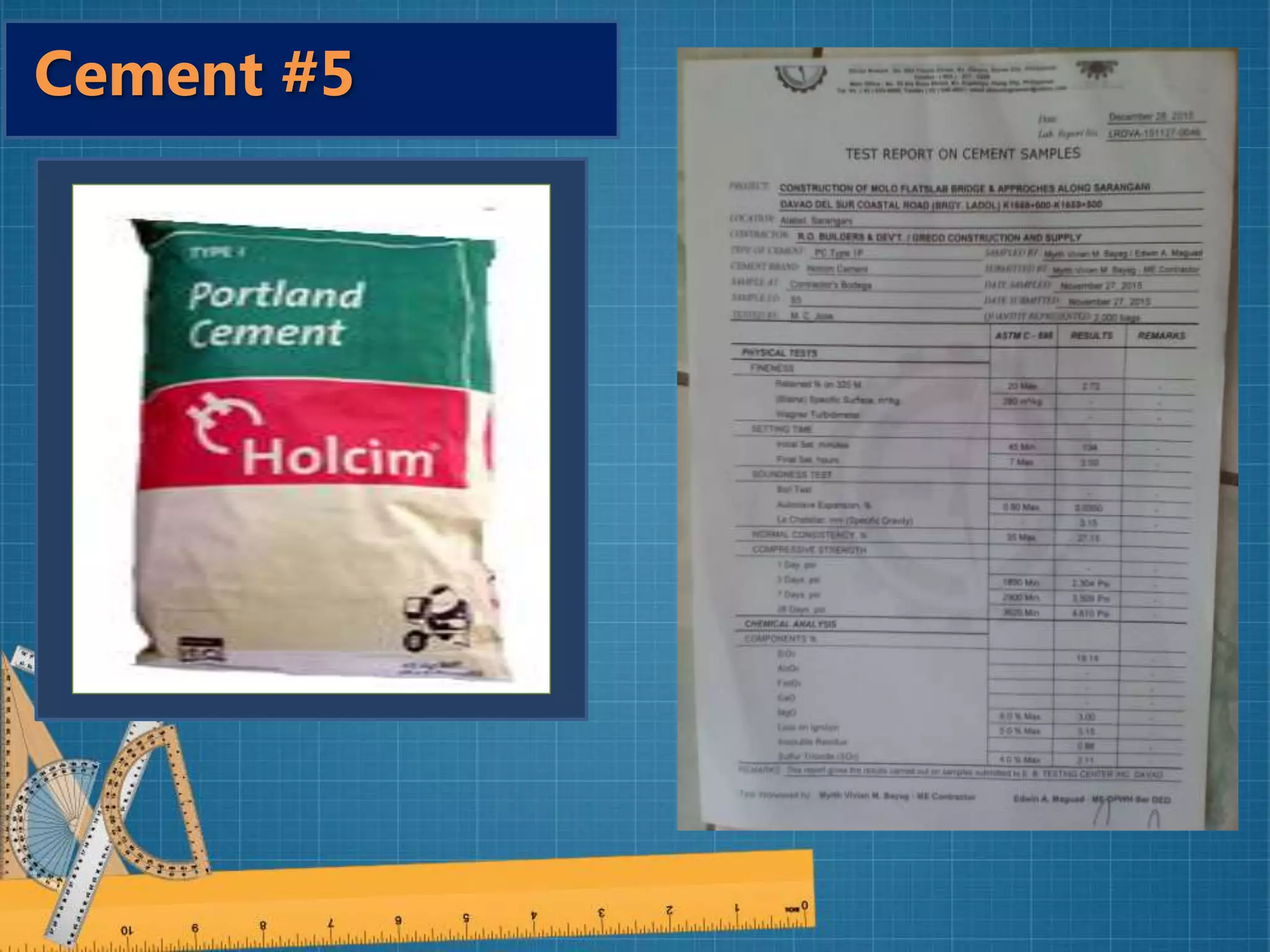

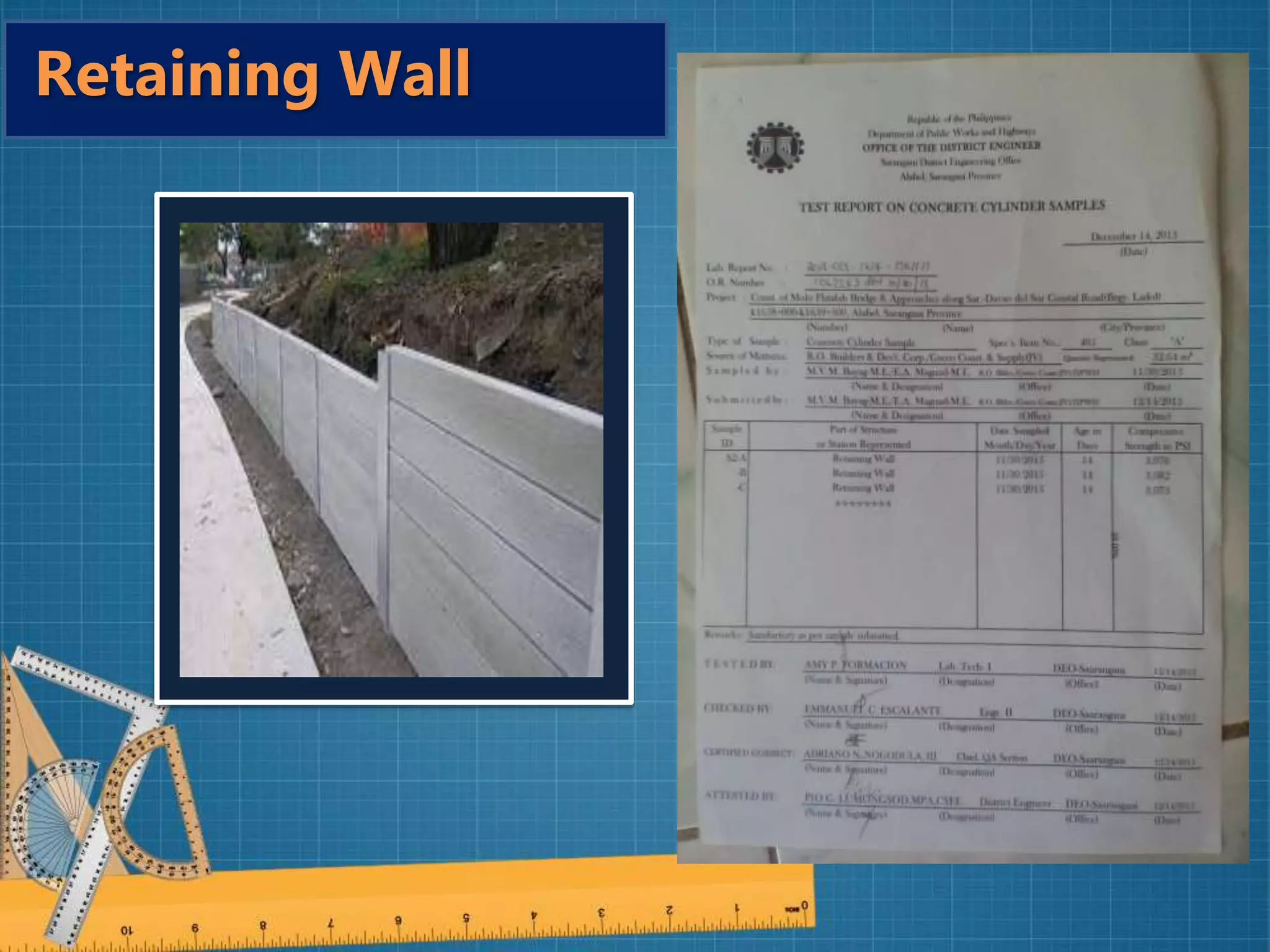

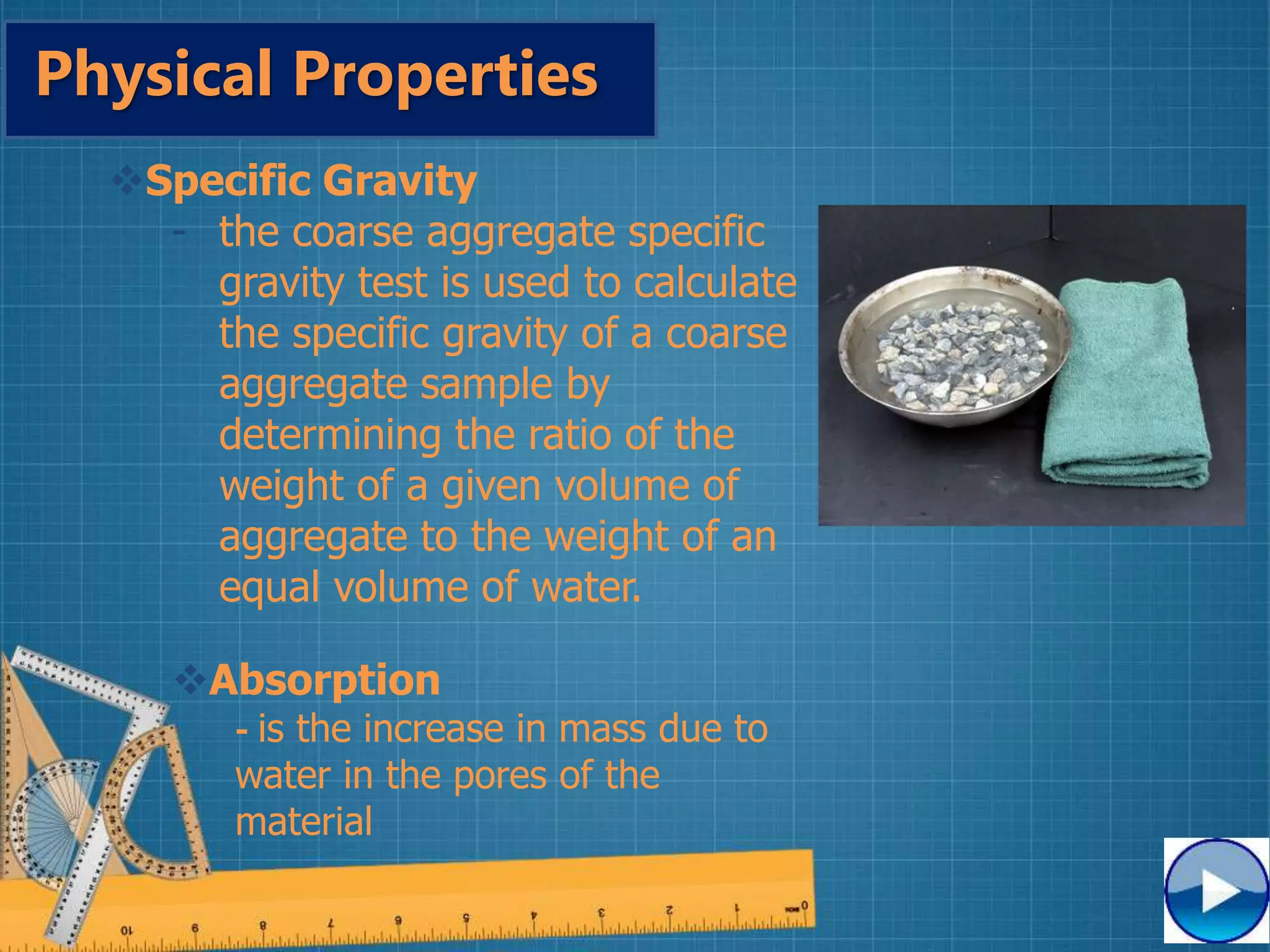

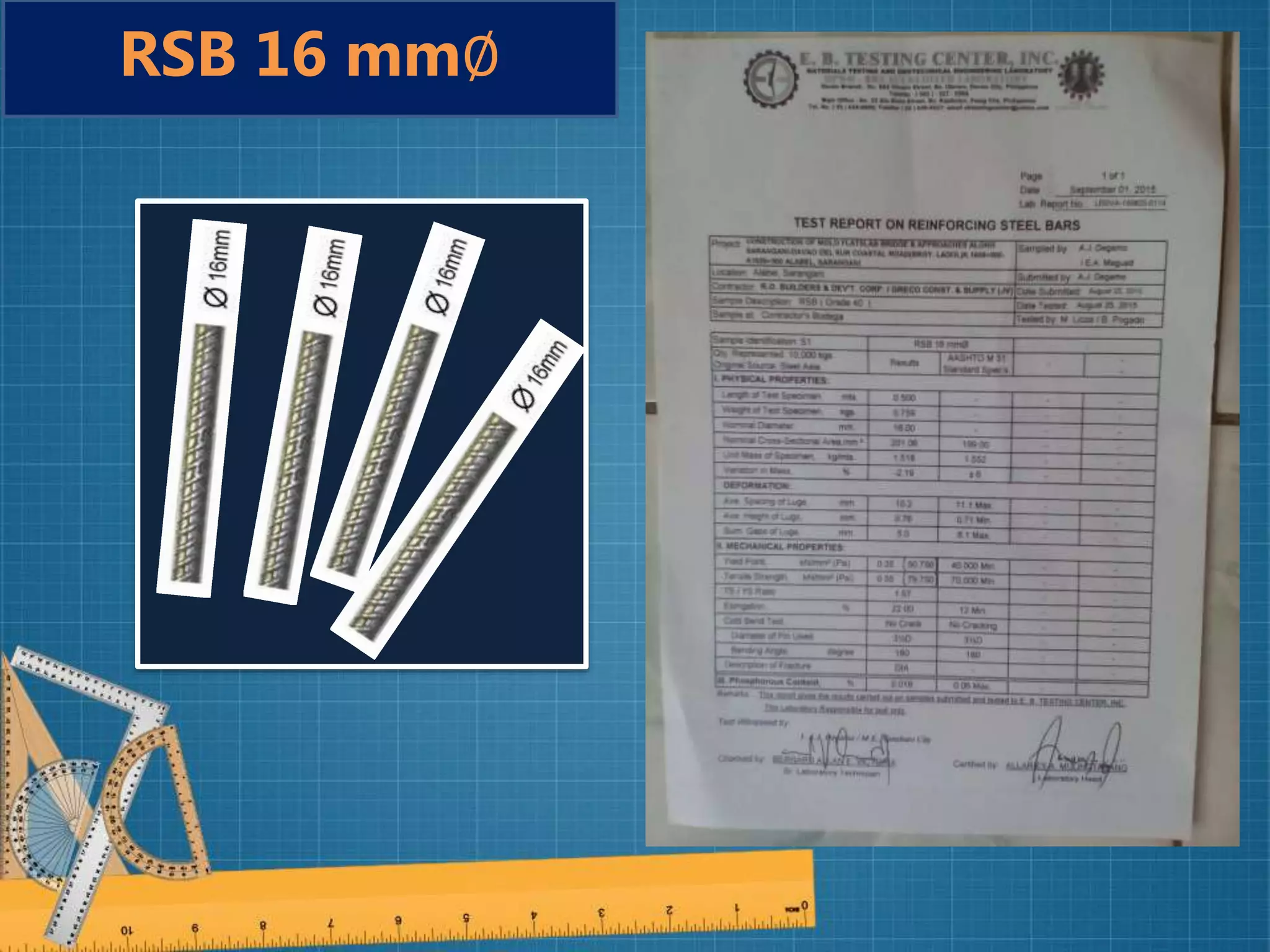

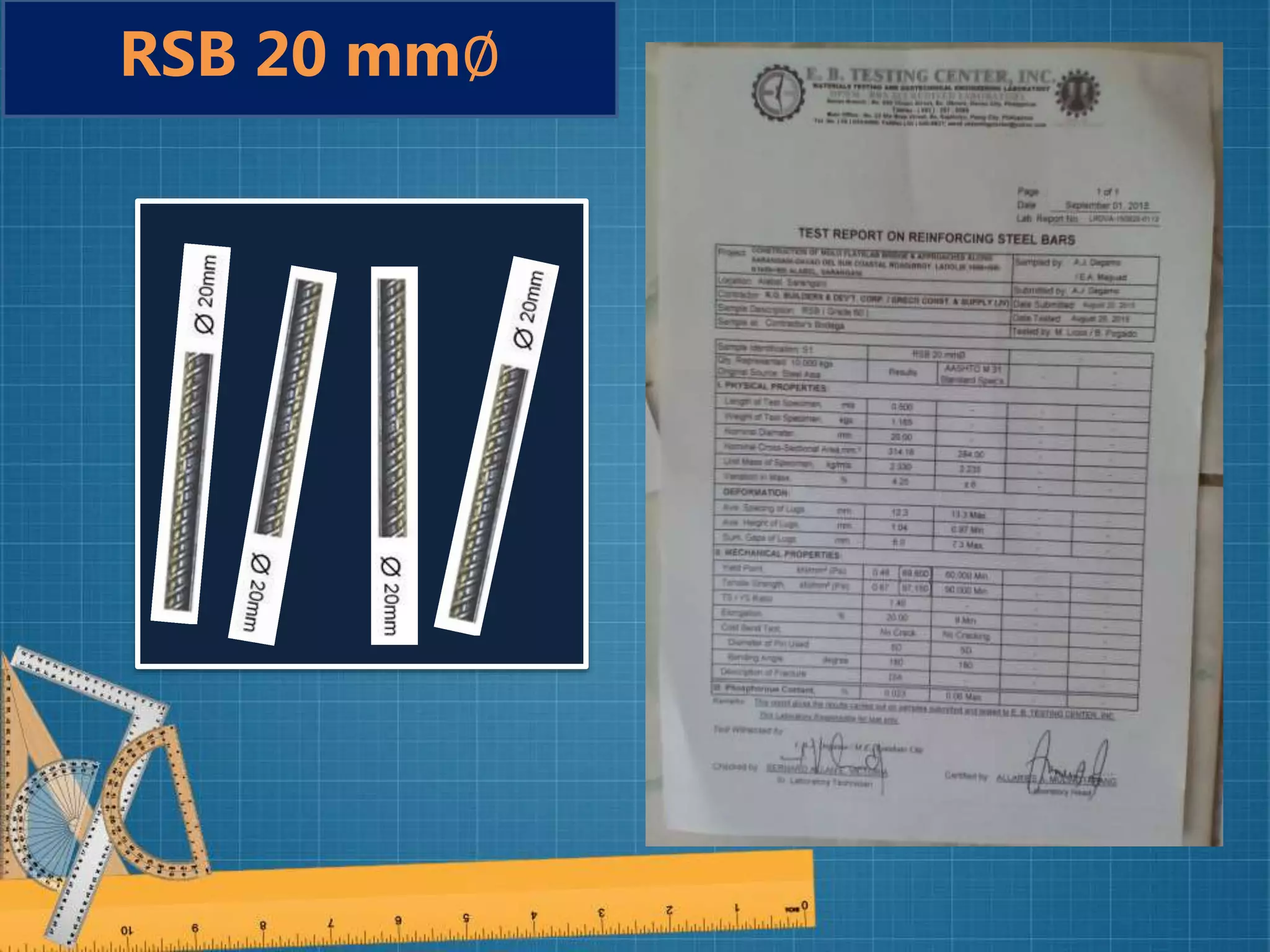

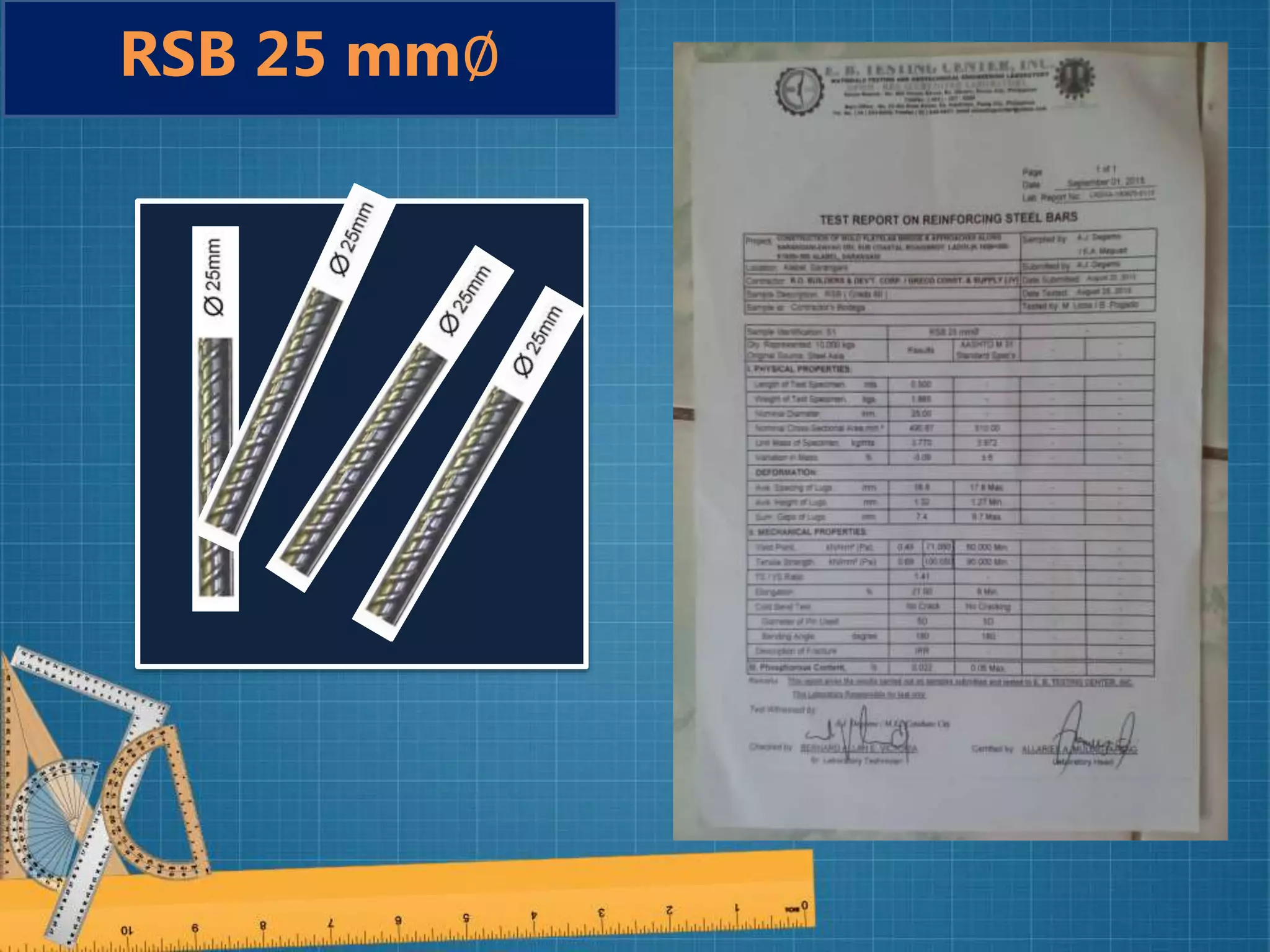

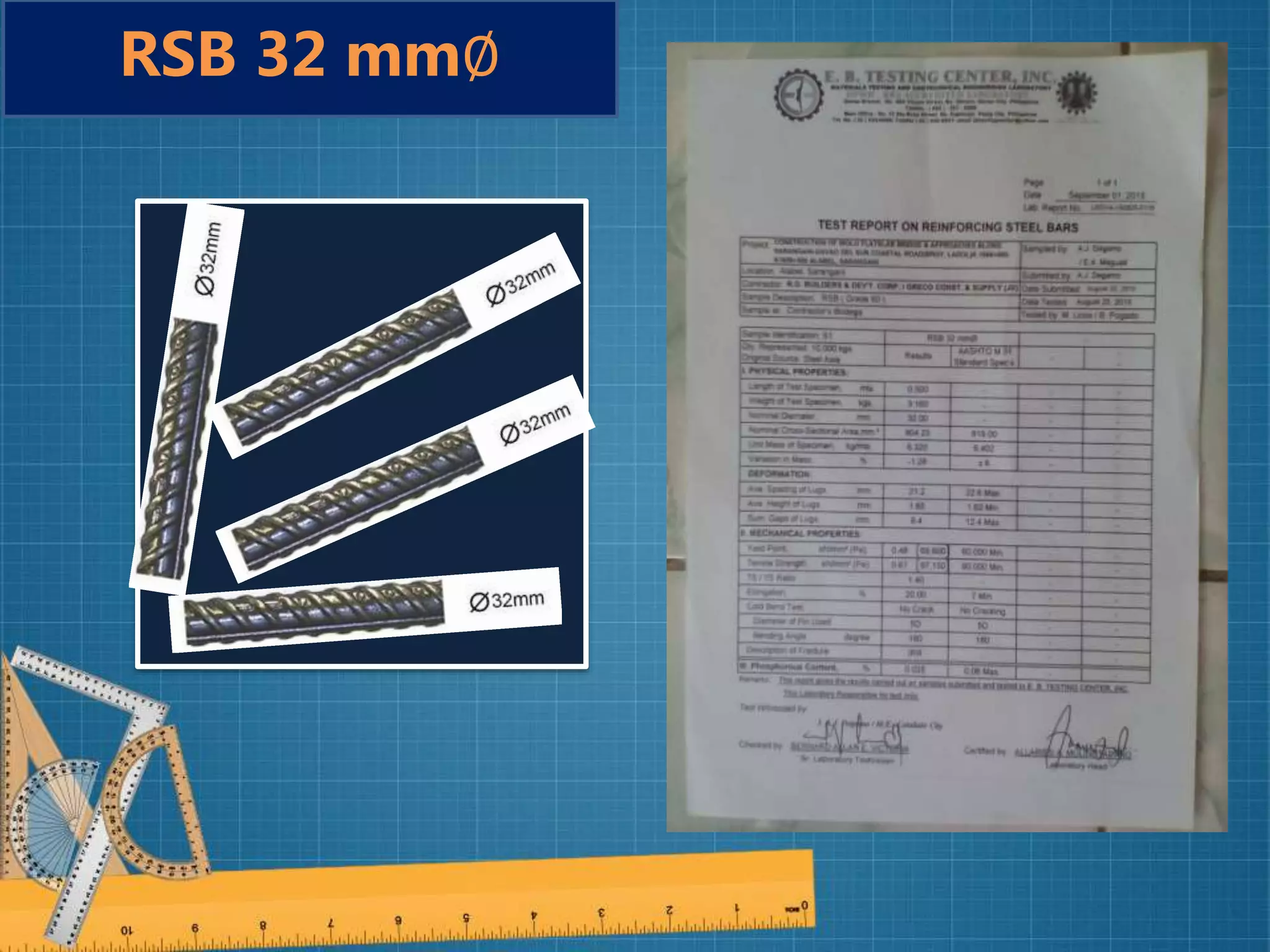

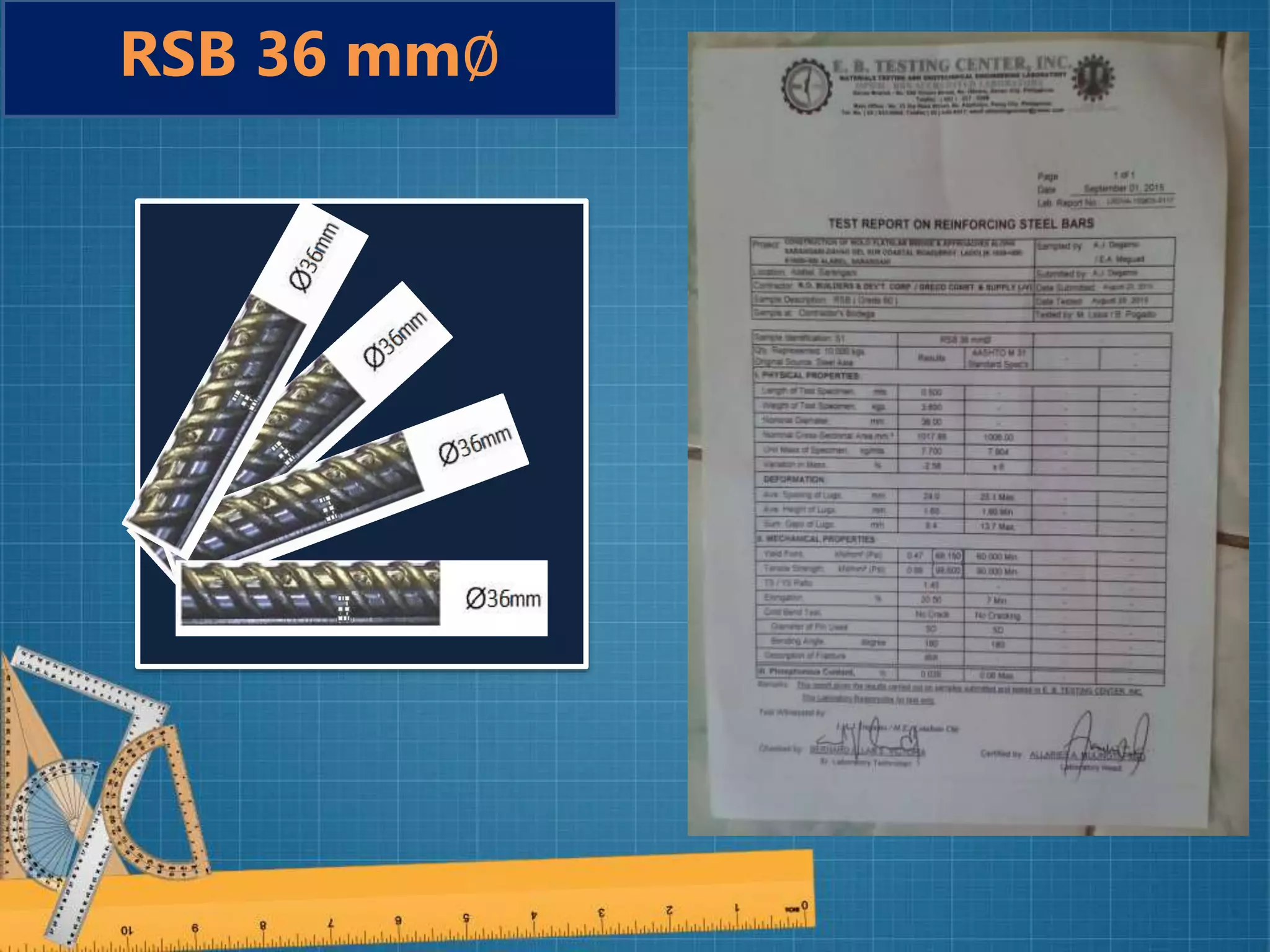

The document discusses quality control and materials testing procedures. It describes how quality control ensures products meet requirements through inspection and testing to find defects. Materials testing examines how materials withstand stresses and forces they may experience. It then provides details on specific tests for cement, aggregates, and reinforcing steel bars to evaluate their physical and mechanical properties and ensure quality standards are met. These include tests for fineness, setting time, strength, hardness, particle size distribution, density, and tensile strength.