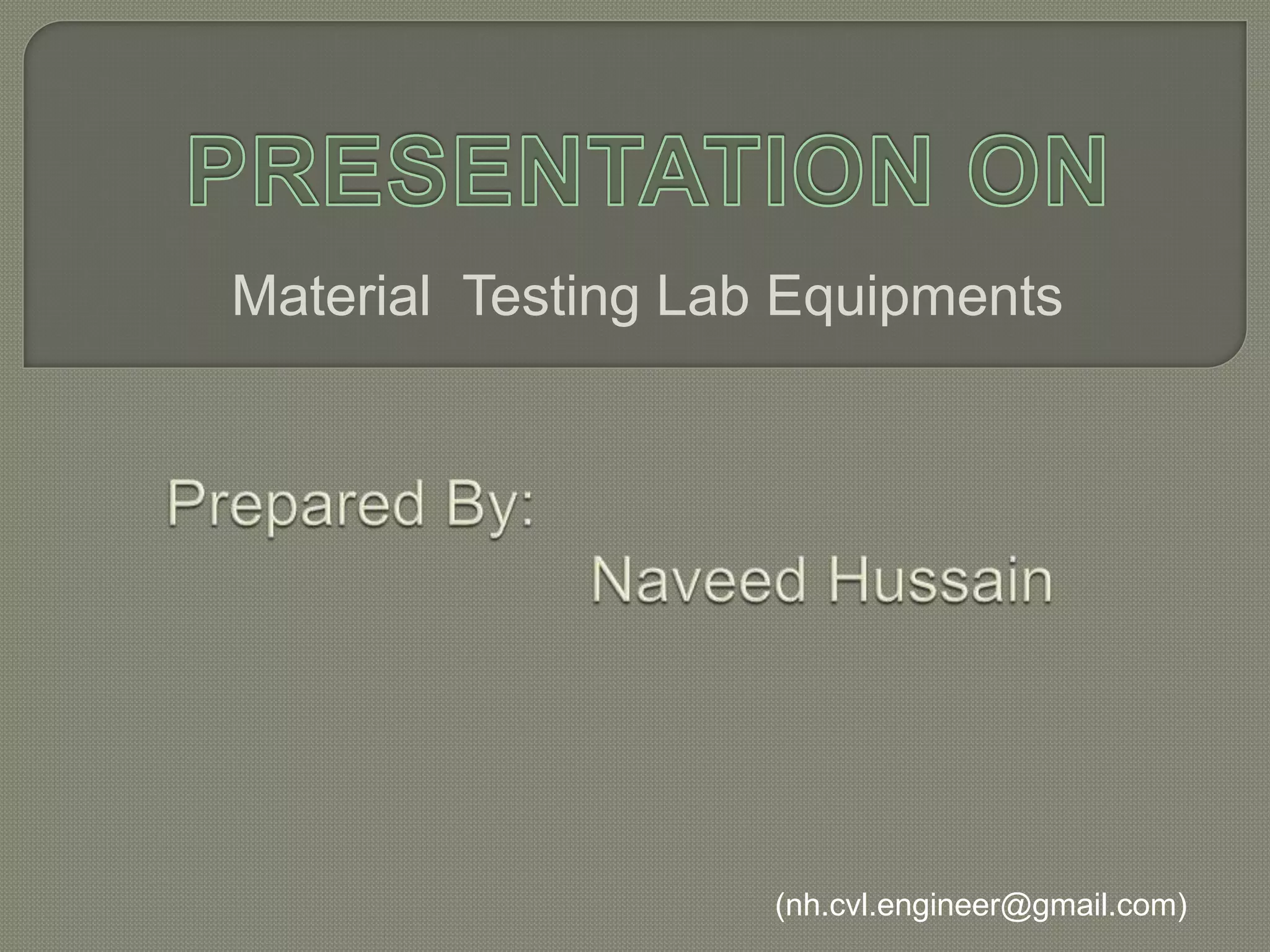

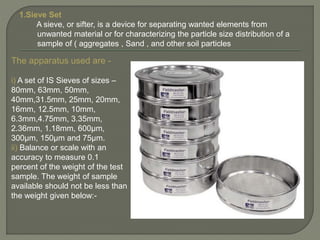

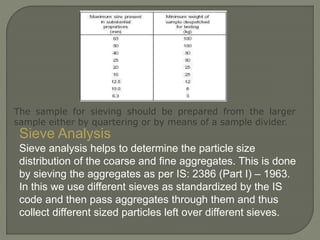

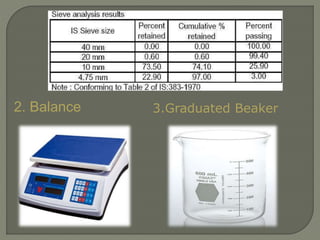

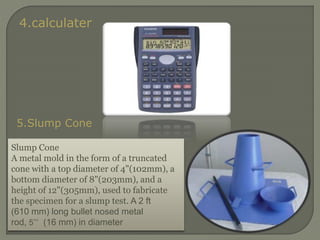

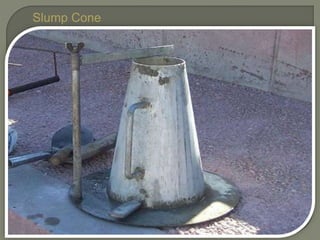

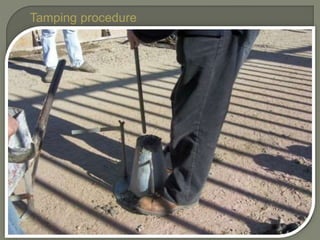

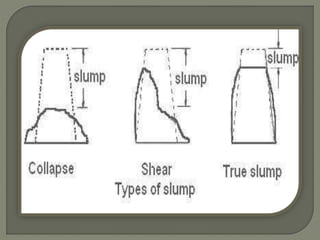

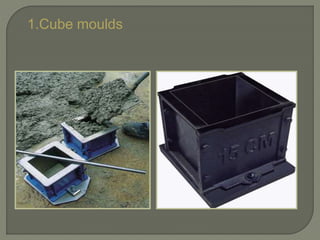

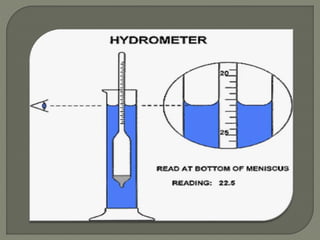

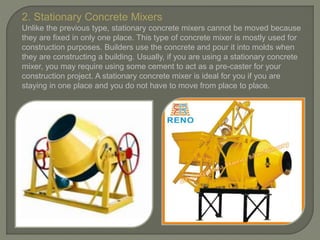

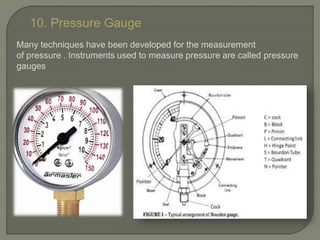

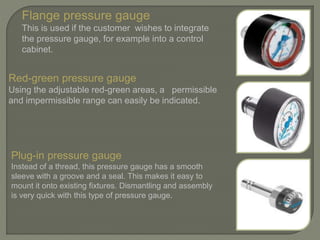

This document lists and describes various types of equipment used in a material testing lab. It includes sieves of different sizes for sieve analysis to determine particle size distribution of aggregates. It also describes a slump cone and procedure for concrete slump testing to measure workability. Other equipment described includes a balance, graduated beaker, calculator, molds, hydrometer, universal testing machine, concrete mixer, pressure gauge, tamping rod, thermometer, internal and external vibrators.