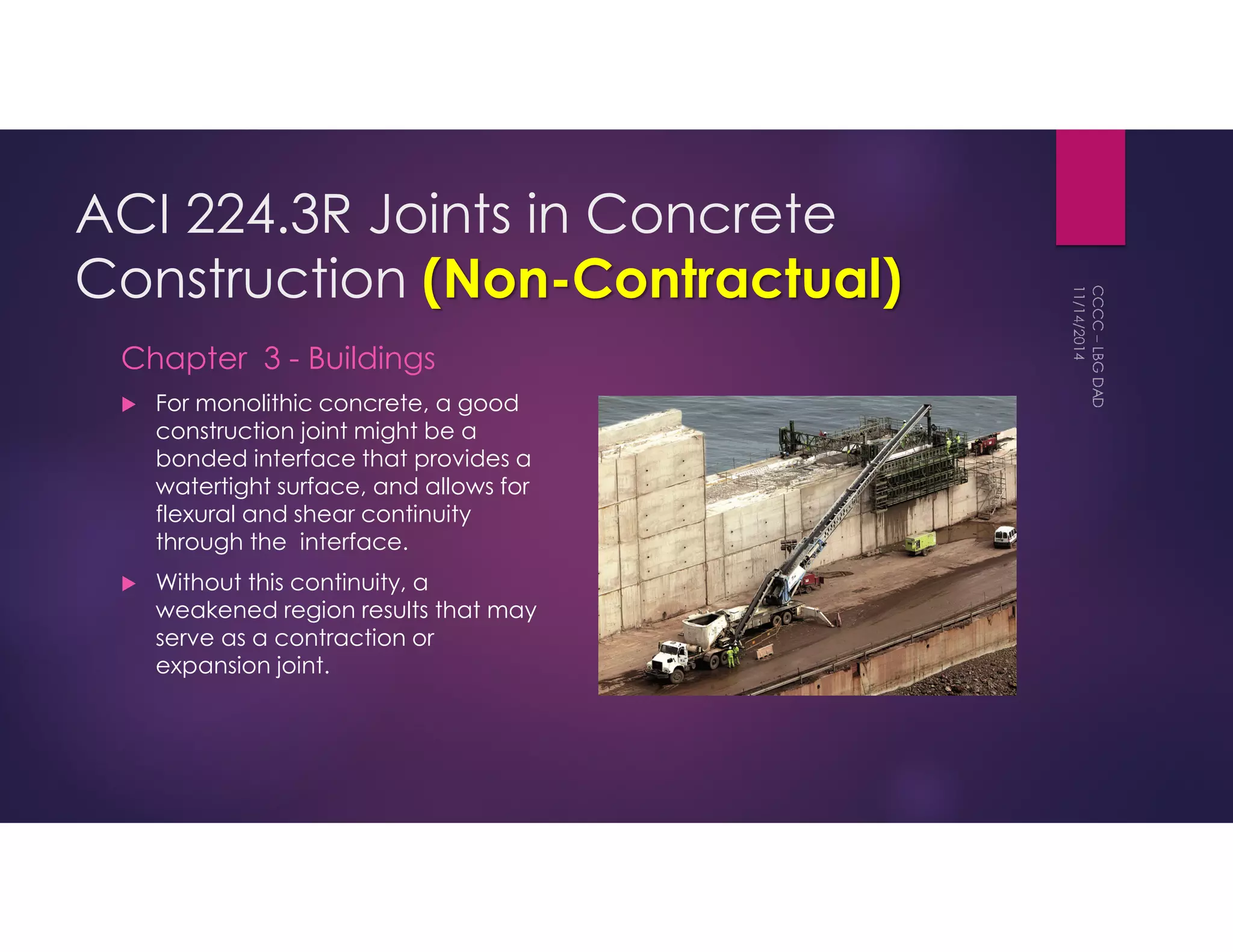

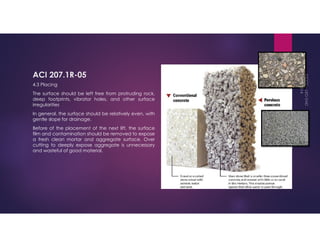

This document outlines best practices for constructing joints in concrete, emphasizing the importance of a well-bonded, watertight interface to maintain structural integrity. It details surface preparation techniques for existing concrete, the significance of proper placement conditions, and methods such as vibration and cleaning to ensure bonding. Additionally, it addresses construction joint considerations for mass concrete structures, including the removal of contaminants and the management of moisture to enhance bond strength.