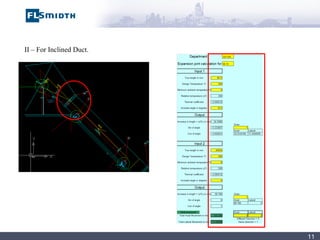

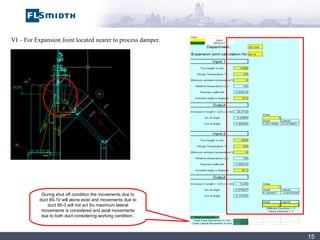

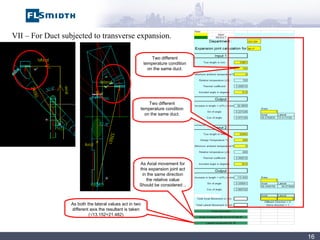

The document presents a comprehensive overview of expansion joints, including their definitions, applications, working principles, and types. It details methodologies for calculating expansion values in different duct configurations and scenarios, aiming to minimize problems and dependencies on utilities. Key considerations include temperature effects, movement types, and the differences between metallic and non-metallic joints.