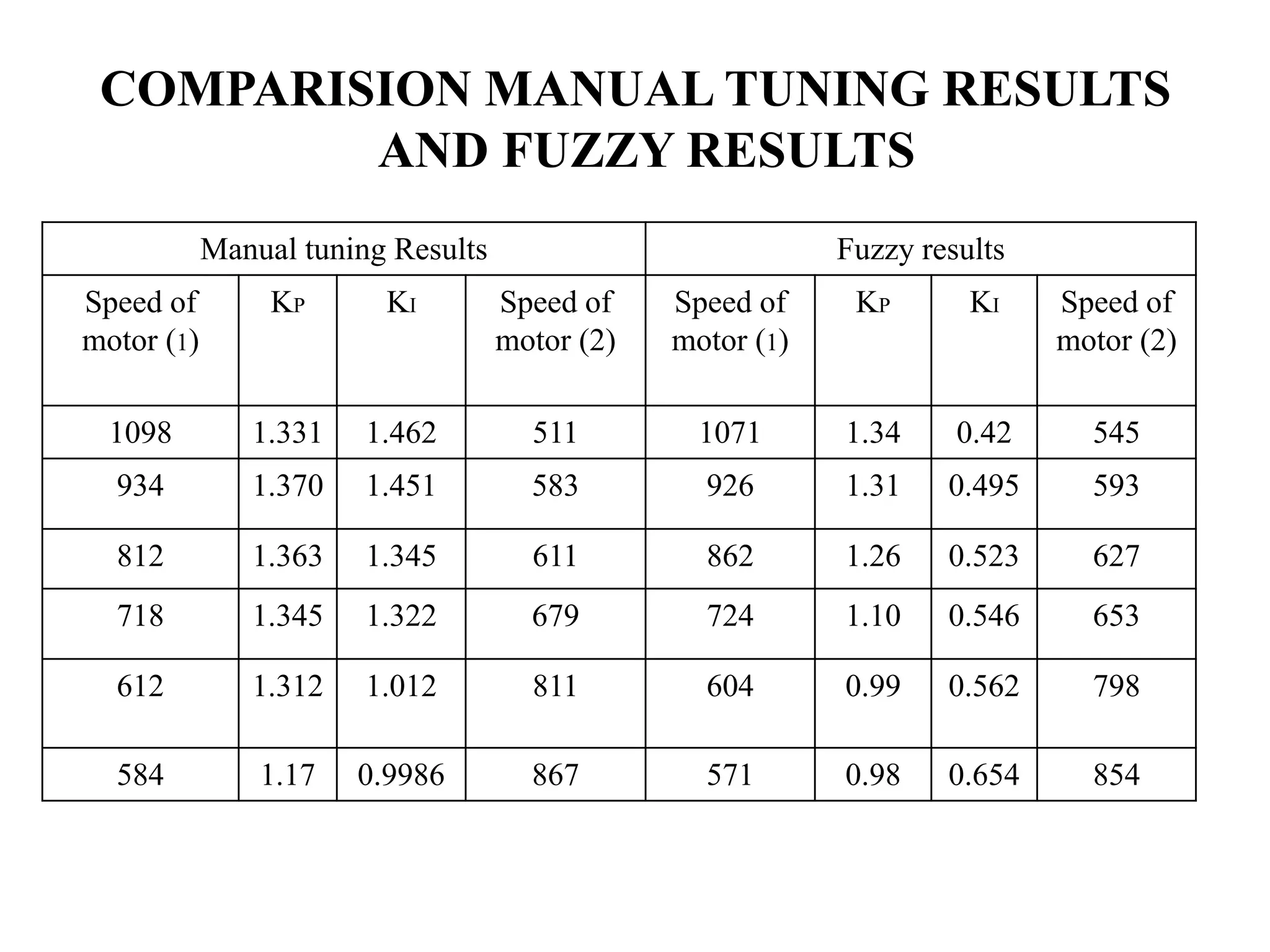

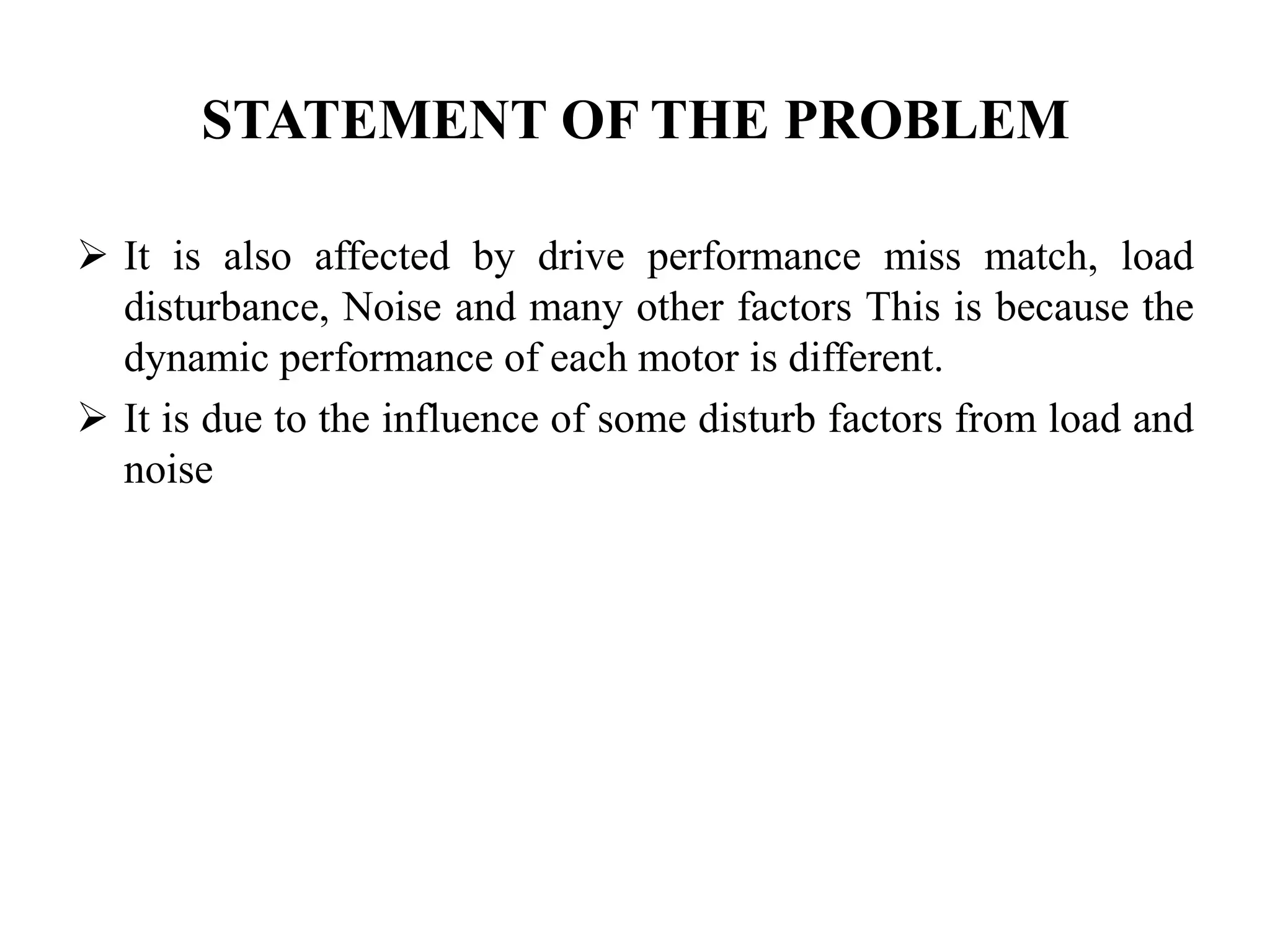

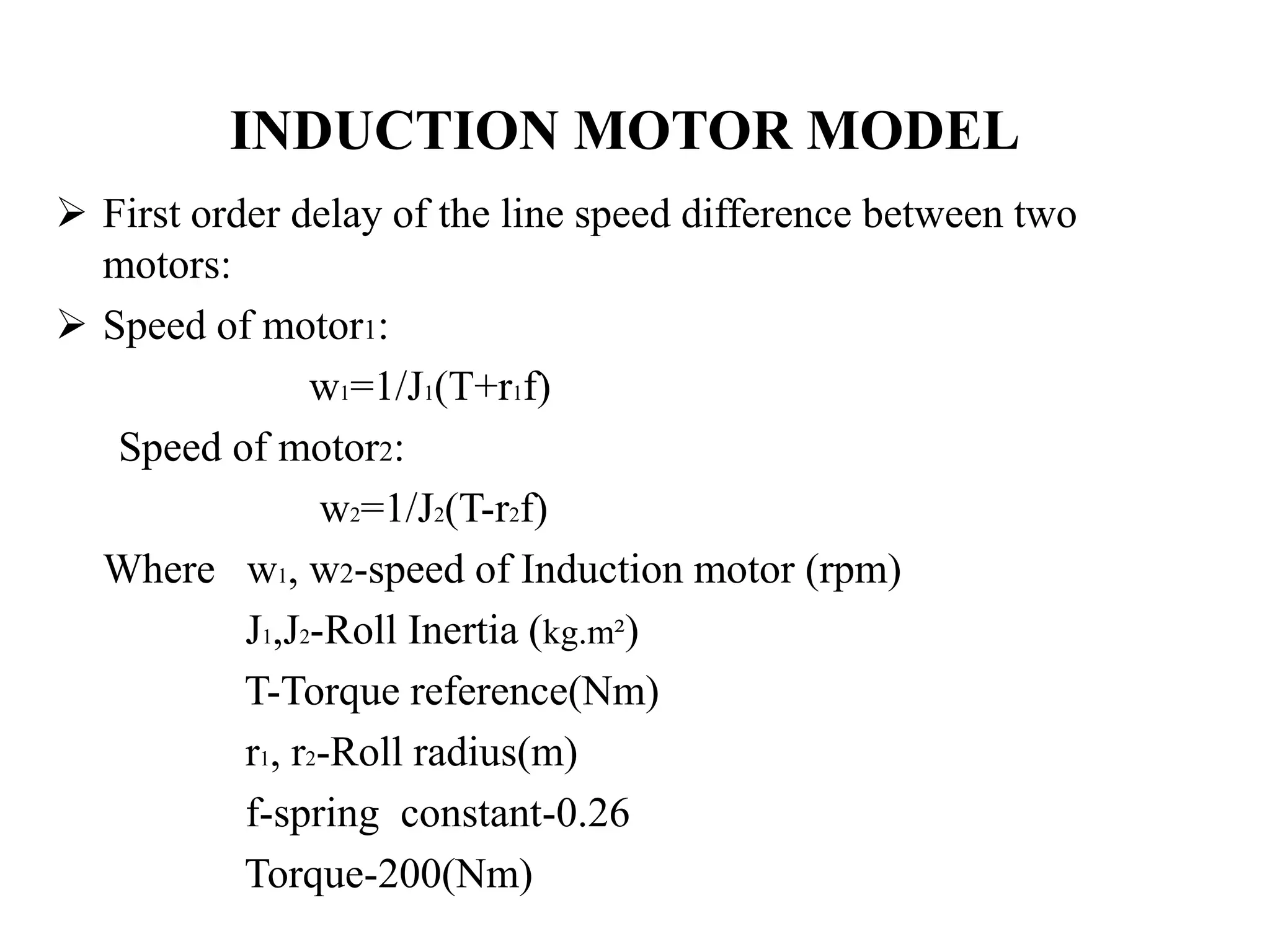

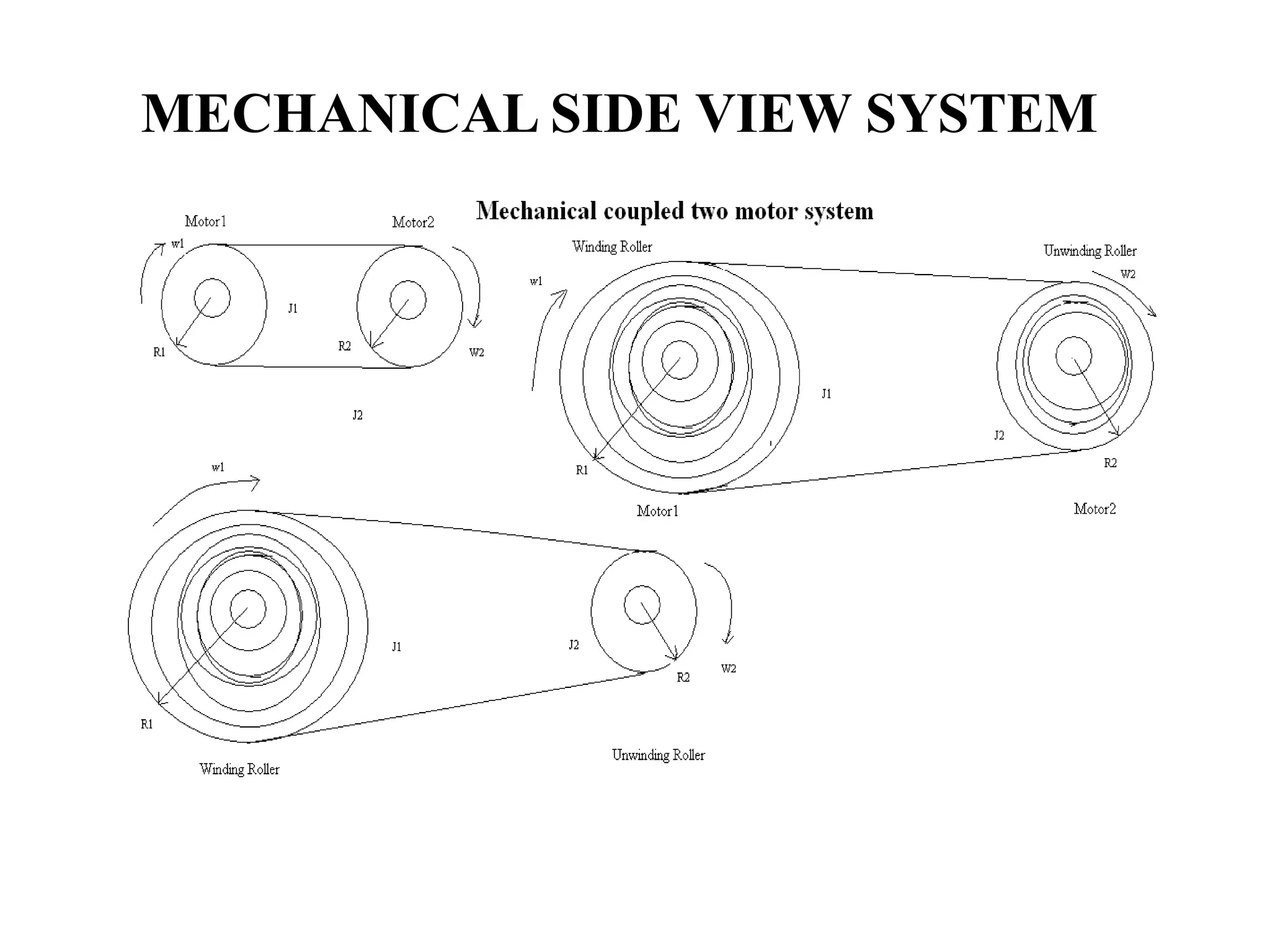

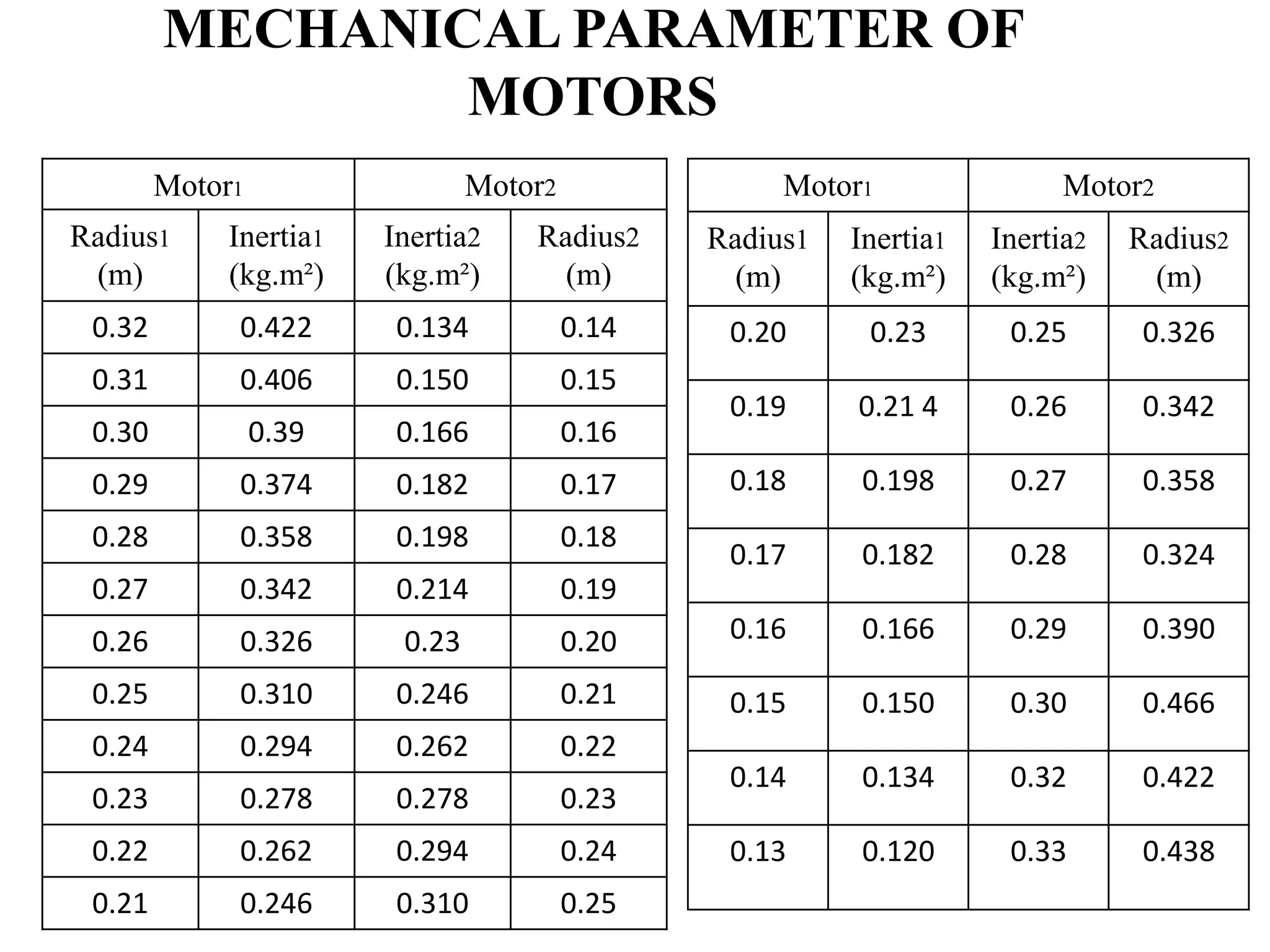

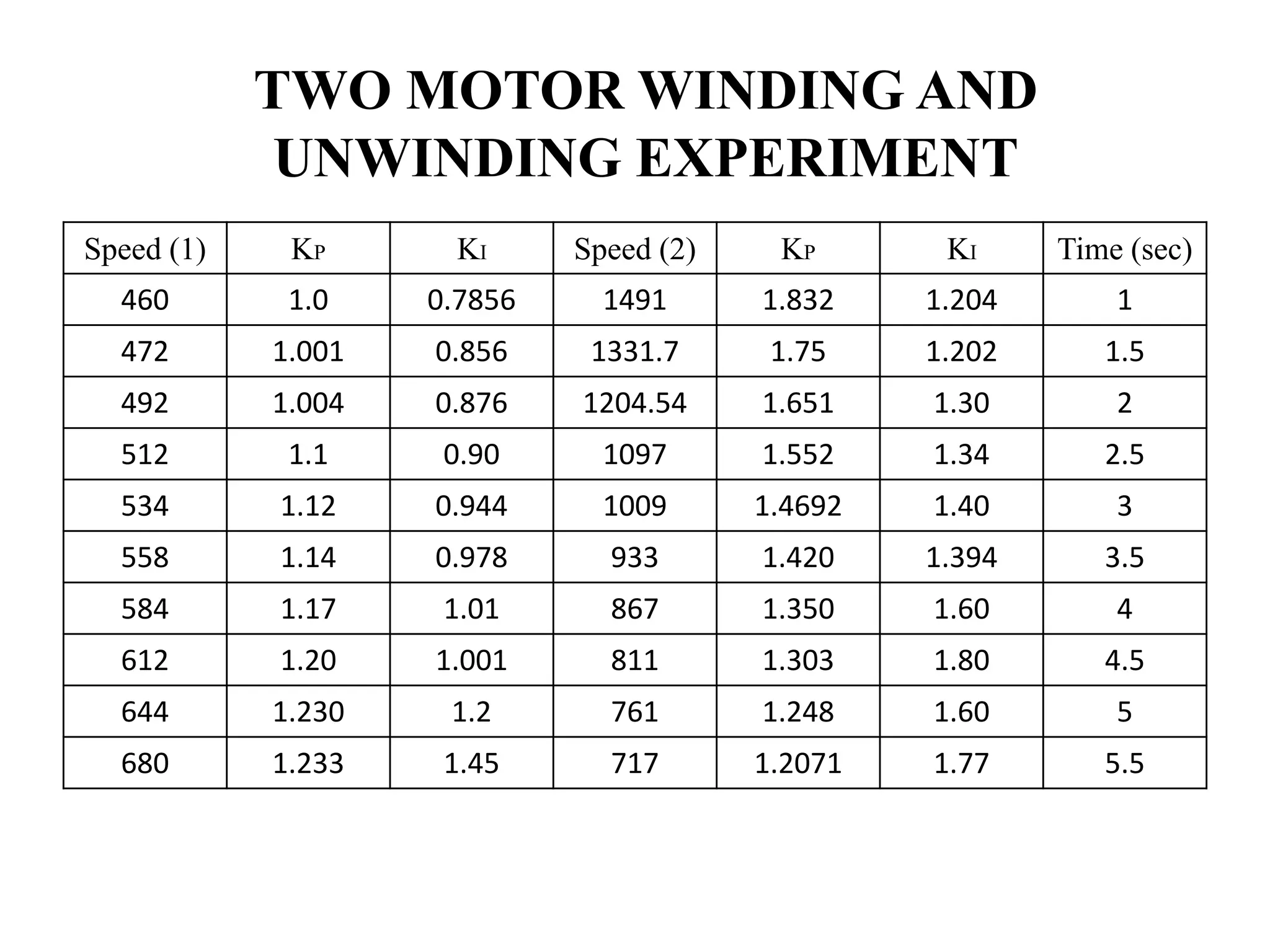

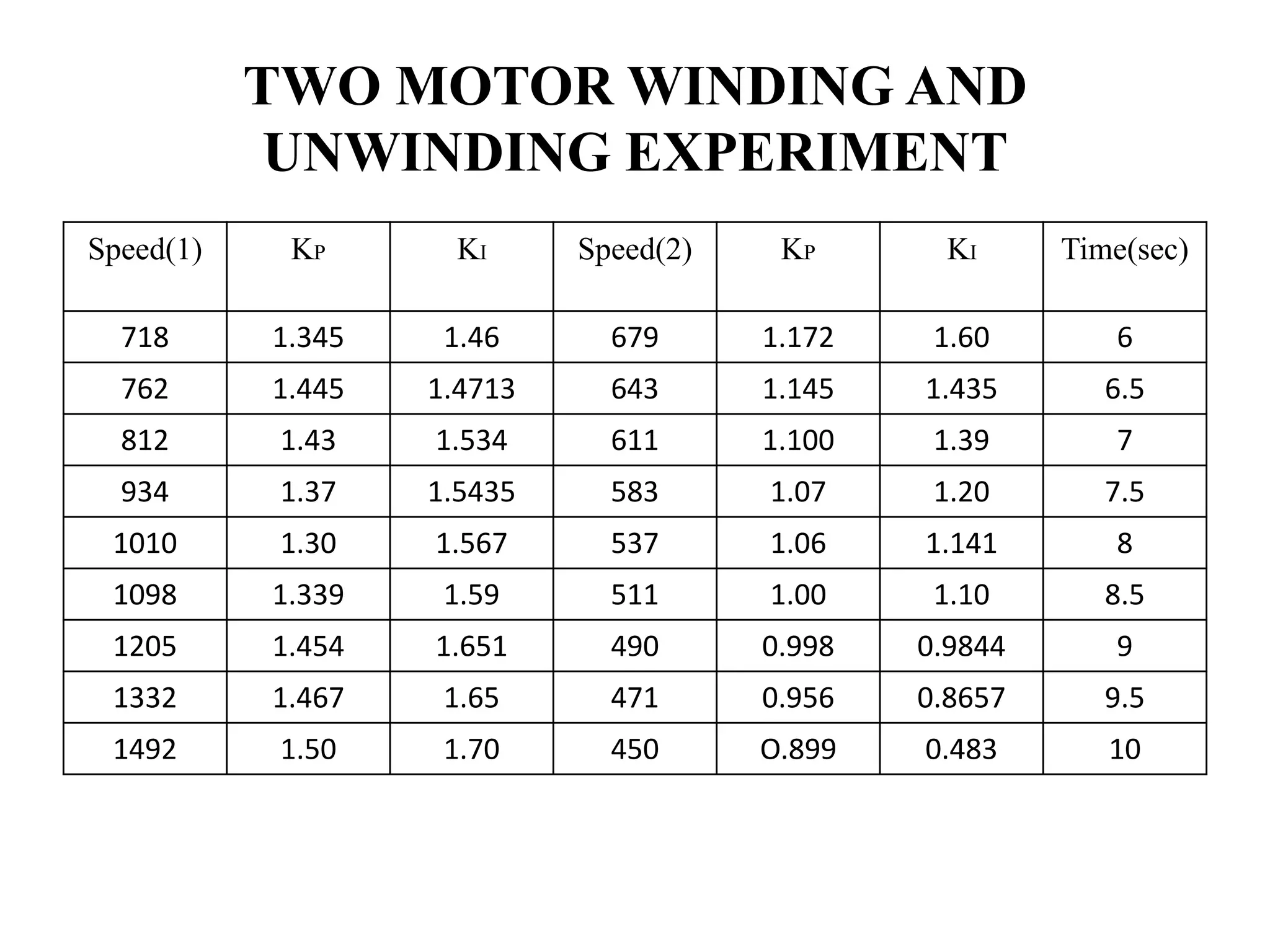

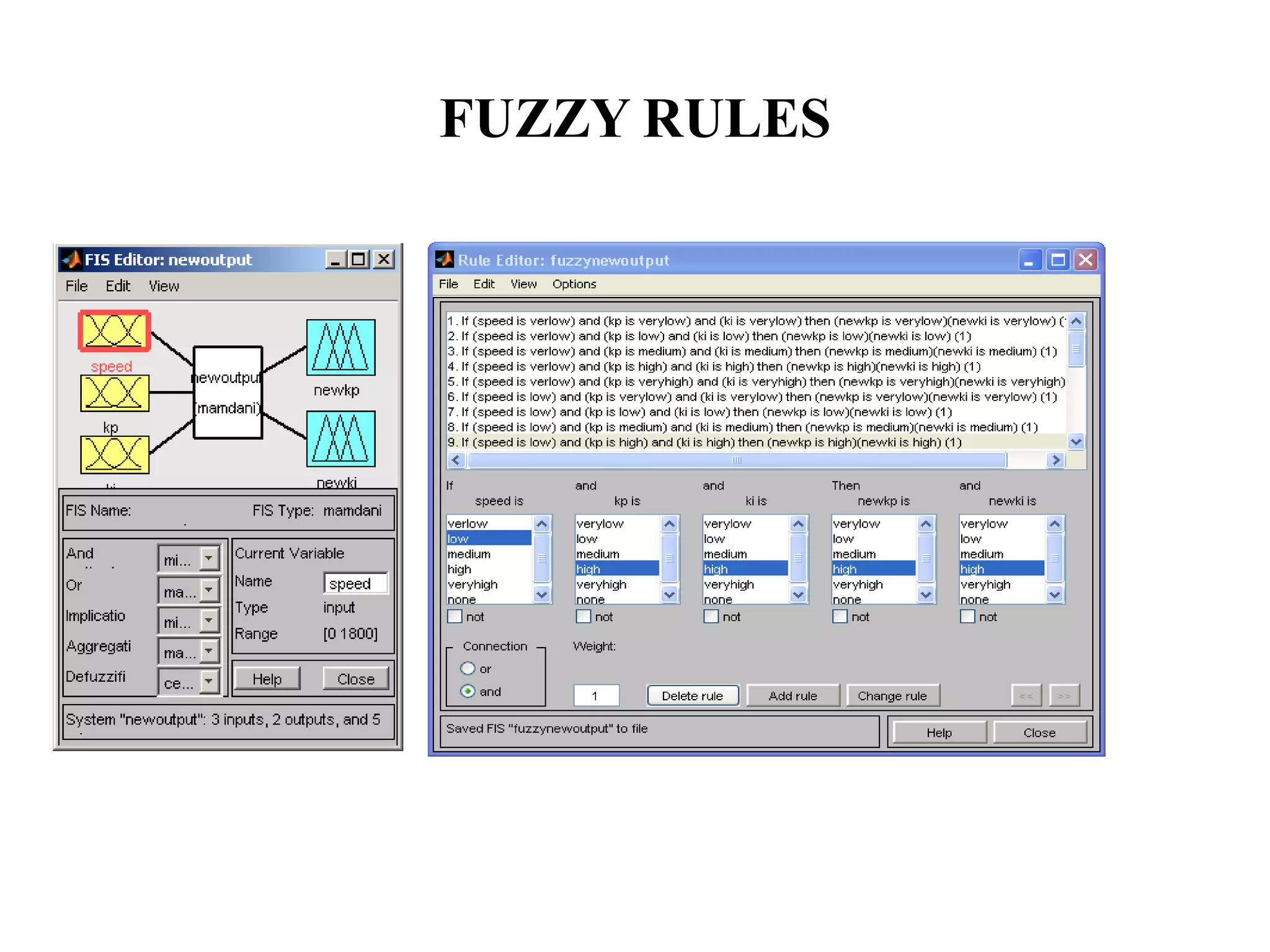

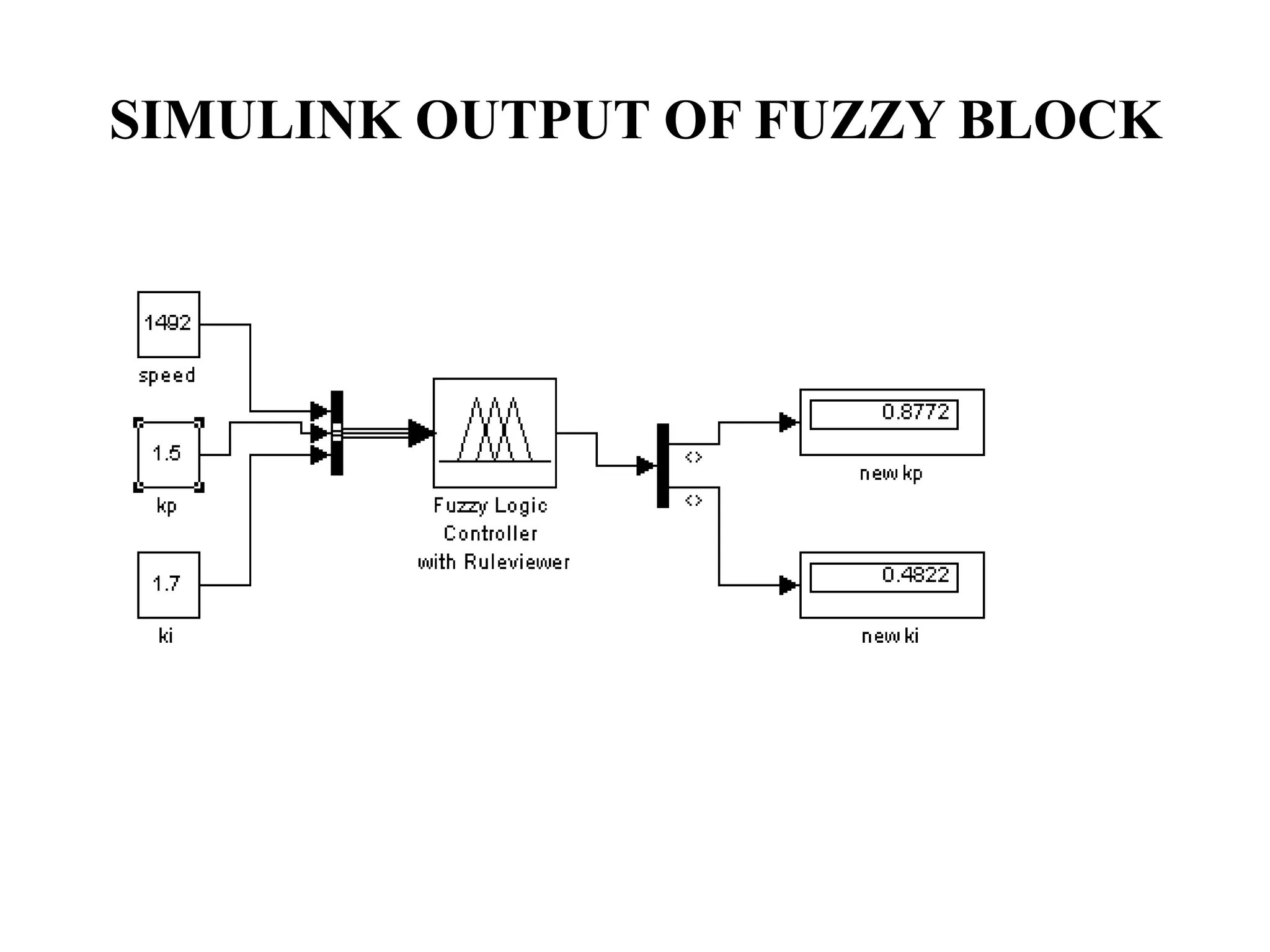

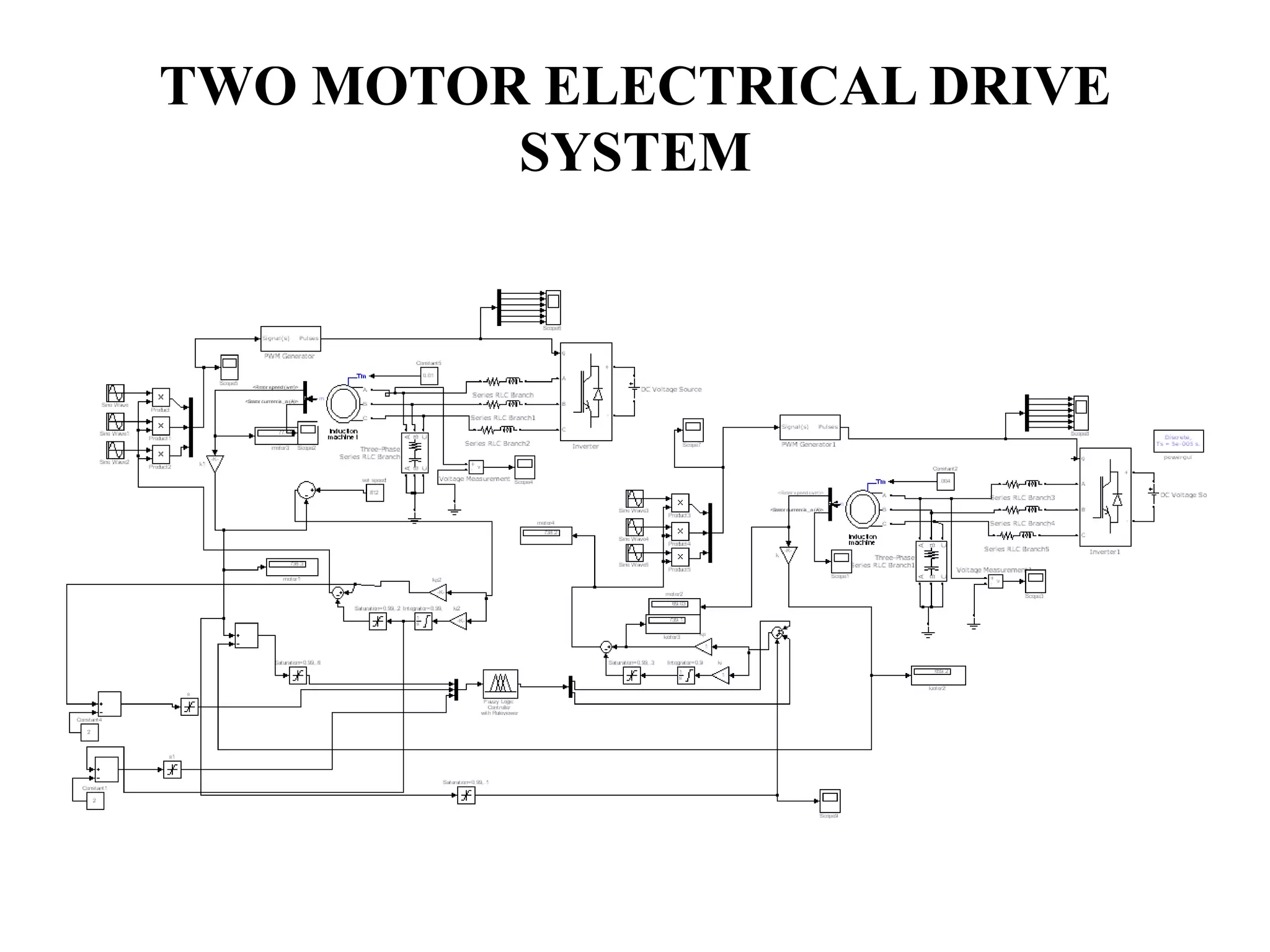

This document presents a method for synchronizing the speed of two motor systems using optimized fuzzy PI control. It proposes using a fuzzy logic-based PI controller to improve motor performance by accounting for factors like load disturbances and noise. The methodology involves developing an induction motor model, collecting experimental speed and tuning parameter data from winding and unwinding the motors, and defining fuzzy logic rules and a Simulink model. Results show the fuzzy controller achieves better synchronization than conventional manual tuning alone.

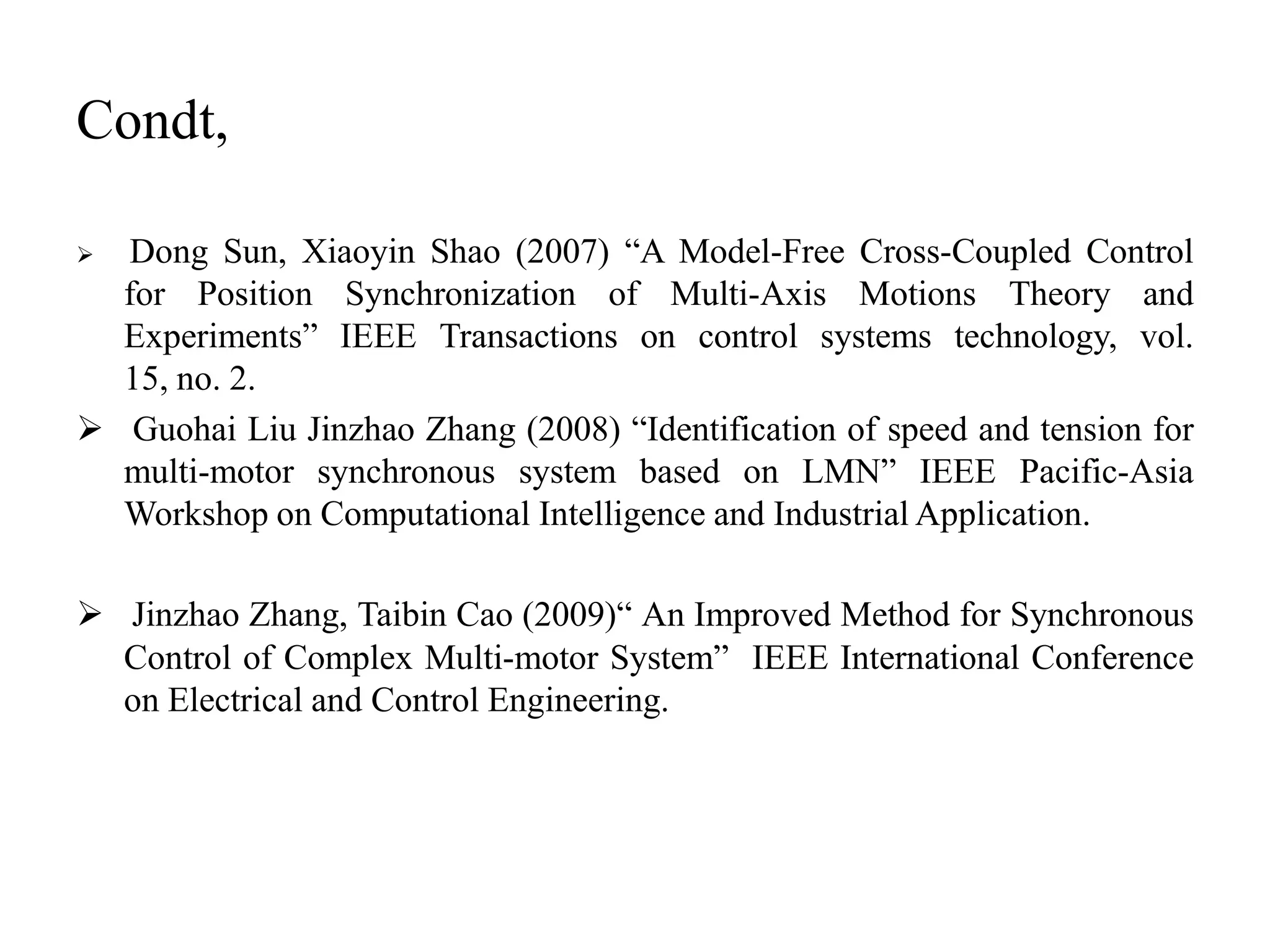

![MOTOR SPEED, KP, KI VALUES

Very low Low Medium High Very High

Speed [0-592] [400-845] [750-1200] [960-1421] [1405-1500]

Proportional [0-0.48] [0.12-1.2] [1.08-1.6] [1.5-1.9] [1.6-2.5]

gain

Integral gain [0-0.7] [0.5-0.9] [0.8-1.3] [1.2-1.6] [1.4-1.9]](https://image.slidesharecdn.com/conferenceppt-120923012316-phpapp02/75/Conference-ppt-13-2048.jpg)