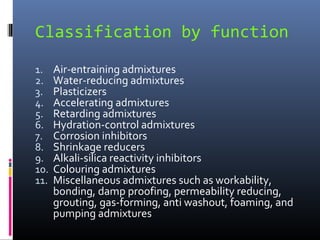

This document discusses different types of concrete admixtures, including their functions and benefits. It describes 11 categories of admixtures: 1) air-entraining, 2) water-reducing, 3) plasticizers, 4) accelerating, 5) retarding, 6) hydration-control, 7) corrosion inhibitors, 8) shrinkage reducers, 9) alkali-silica reactivity inhibitors, 10) coloring, and 11) miscellaneous. For each category, it provides a brief explanation of what the admixture does and why it is used to improve properties of concrete. The document emphasizes that admixtures are added to reduce costs, achieve specific properties, and maintain quality during mixing, transport,

![RETARDING ADMIXTURES

Retarding admixtures are used to delay the rate of

setting of concrete. High temperatures of fresh

concrete (30°C[86°F]) are often the cause of an

increased rate of hardening that makes placing and

finishing difficult.

One of the most practical methods of counteracting

this effect is to reduce the temperature of the

concrete by cooling the mixing water and/or the

aggregates. Retarders do not decrease the initial

temperature of concrete.

The bleeding rate and bleeding capacity of concrete

is increased with retarders.](https://image.slidesharecdn.com/concreteadmixtures-150517102319-lva1-app6891/85/Concrete-admixtures-10-320.jpg)