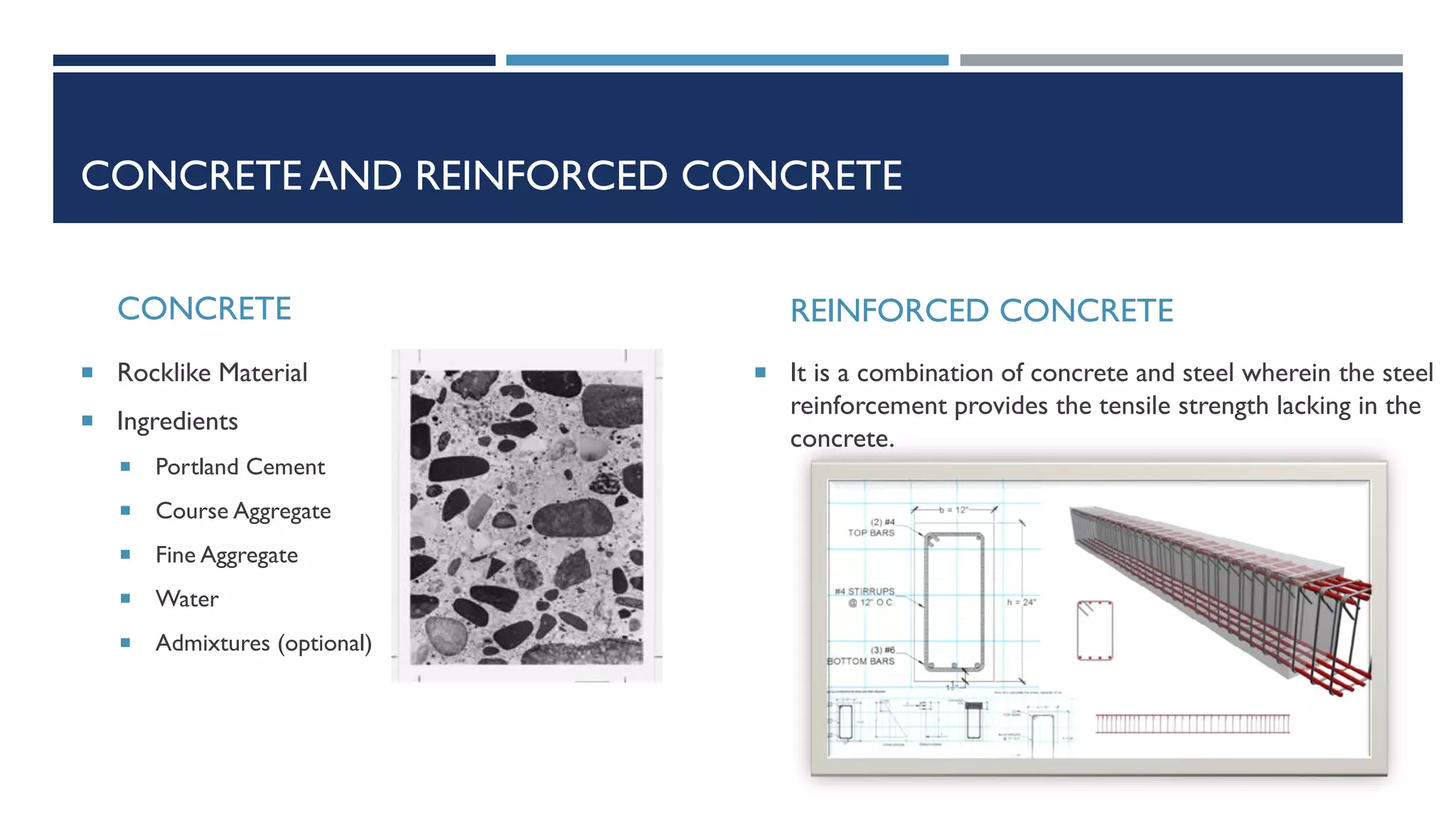

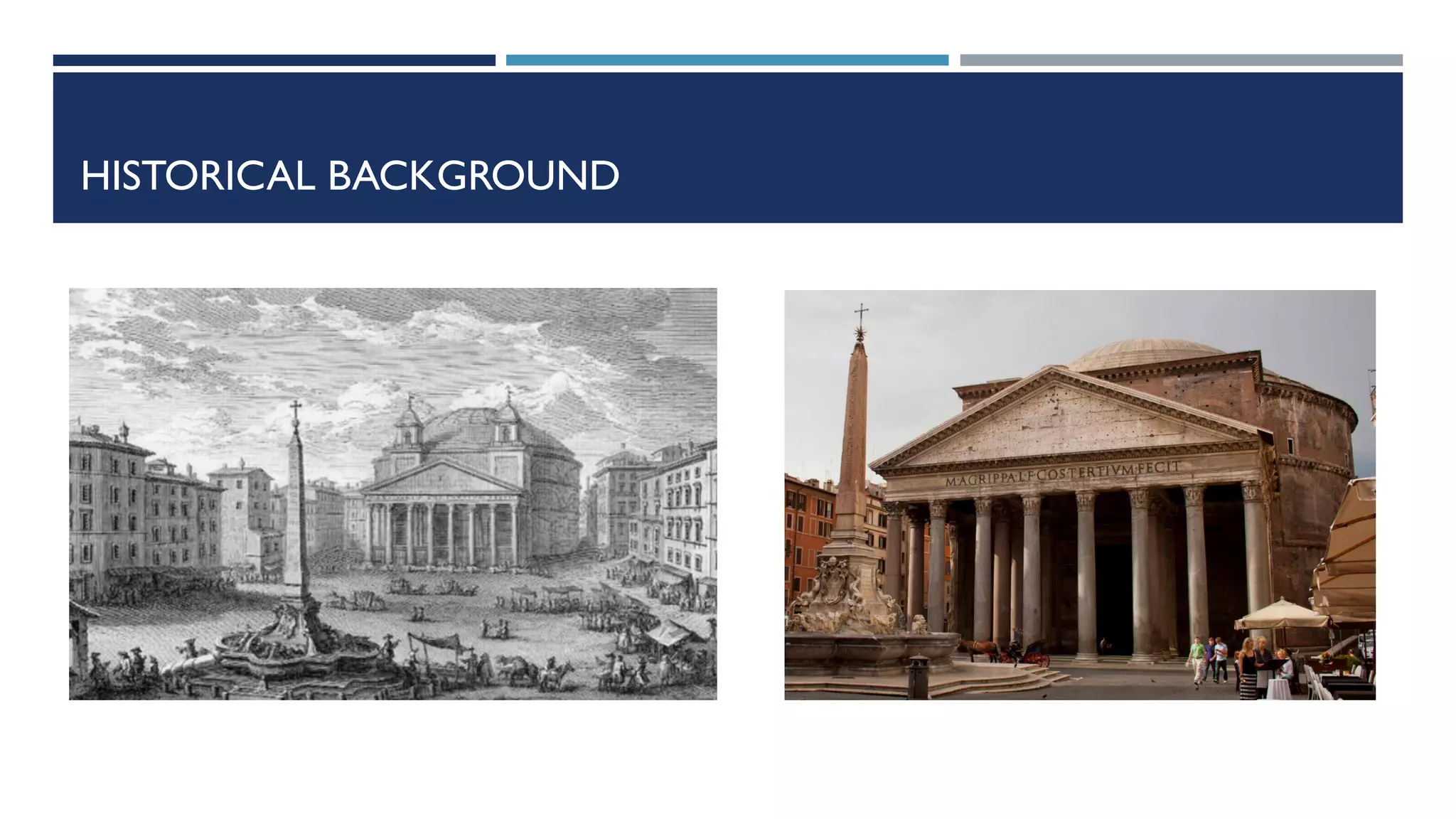

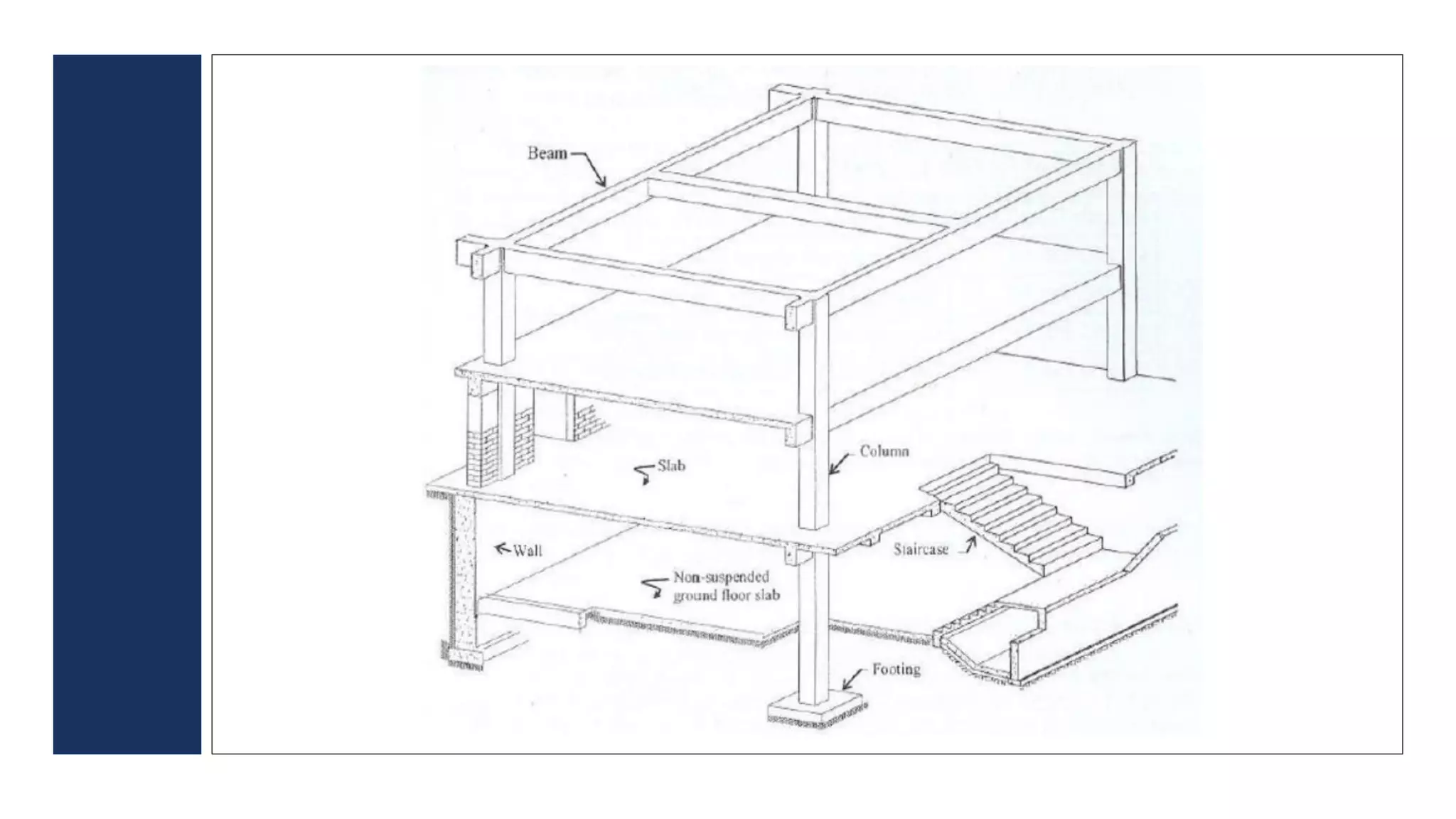

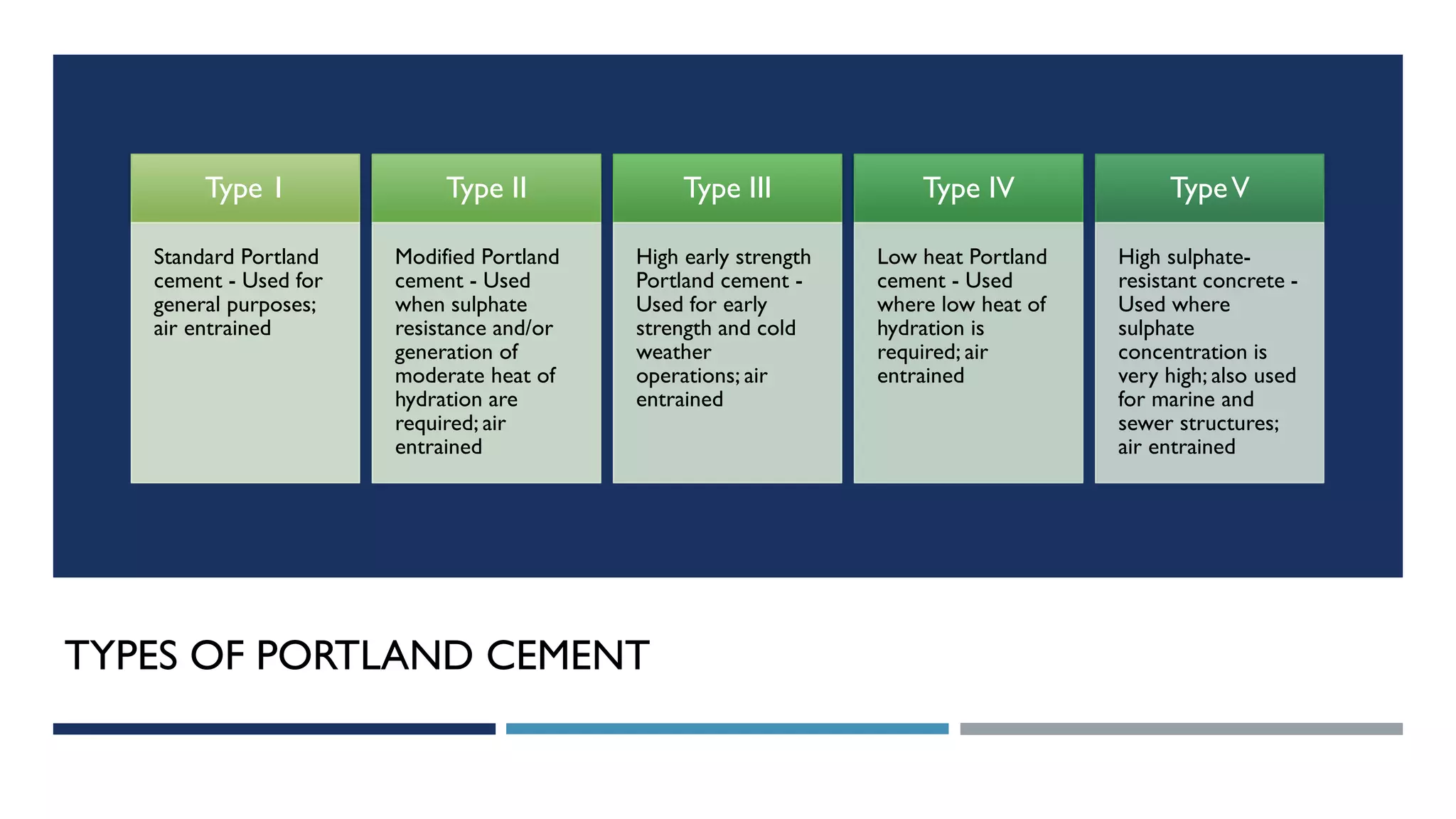

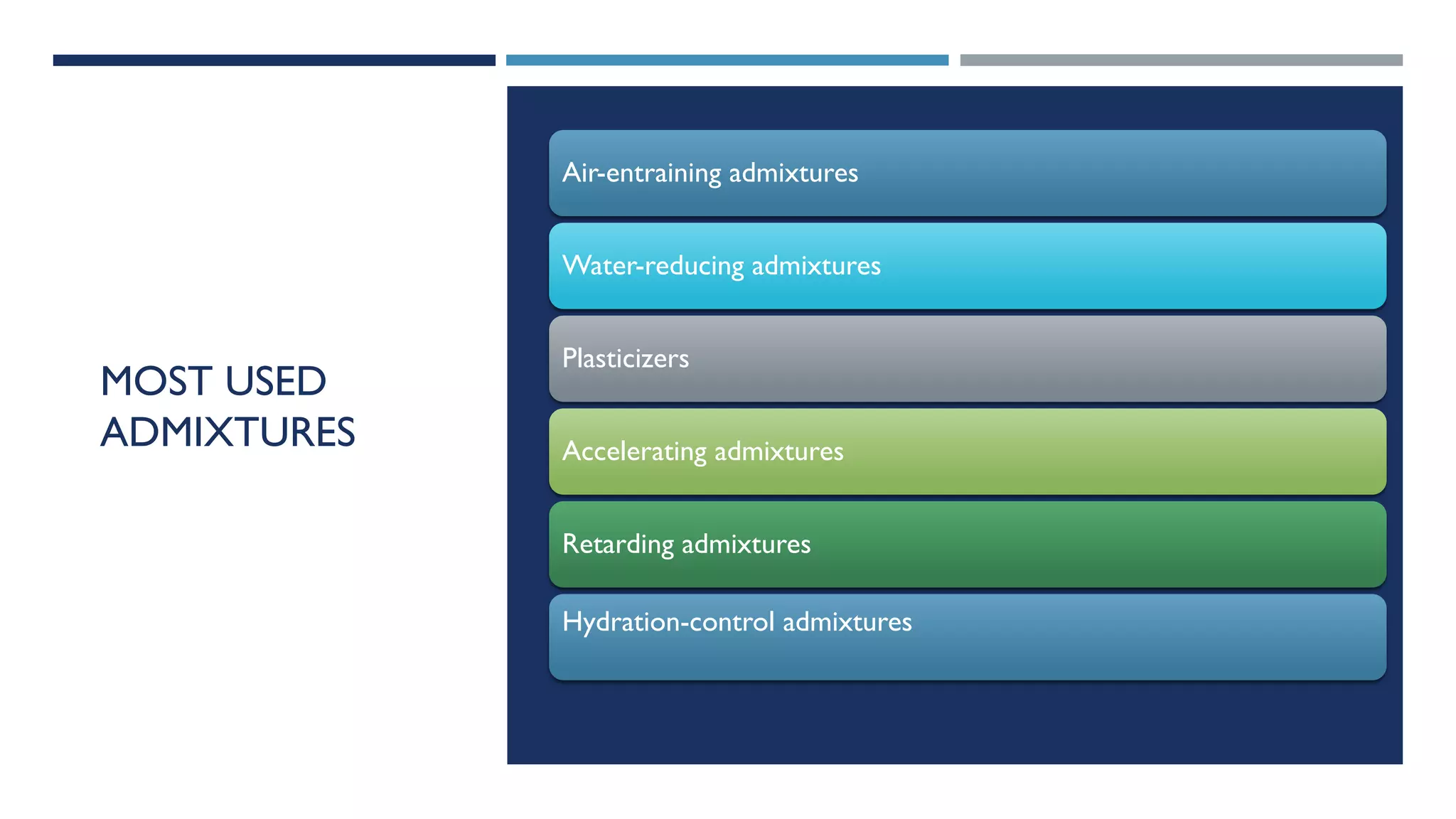

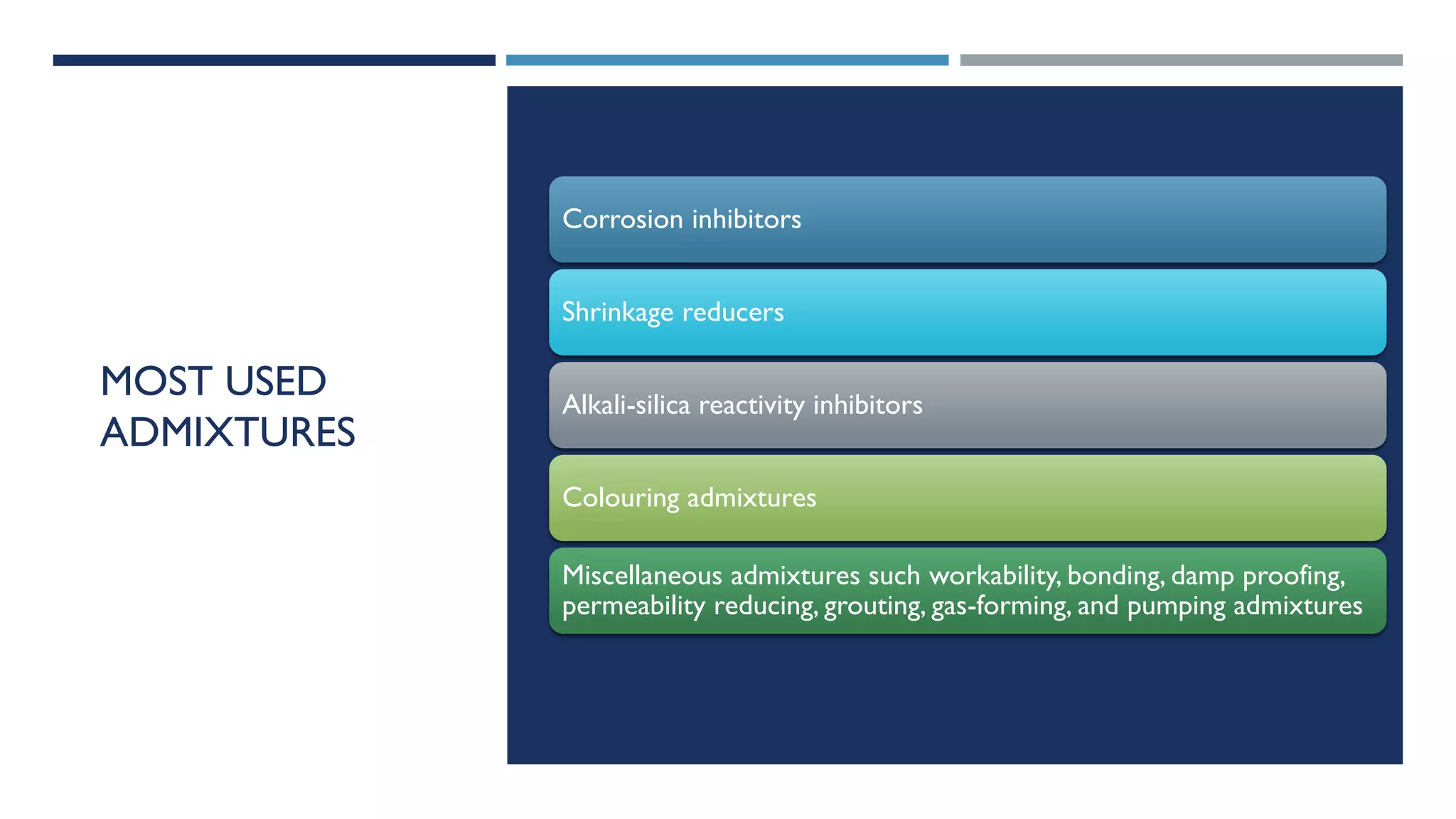

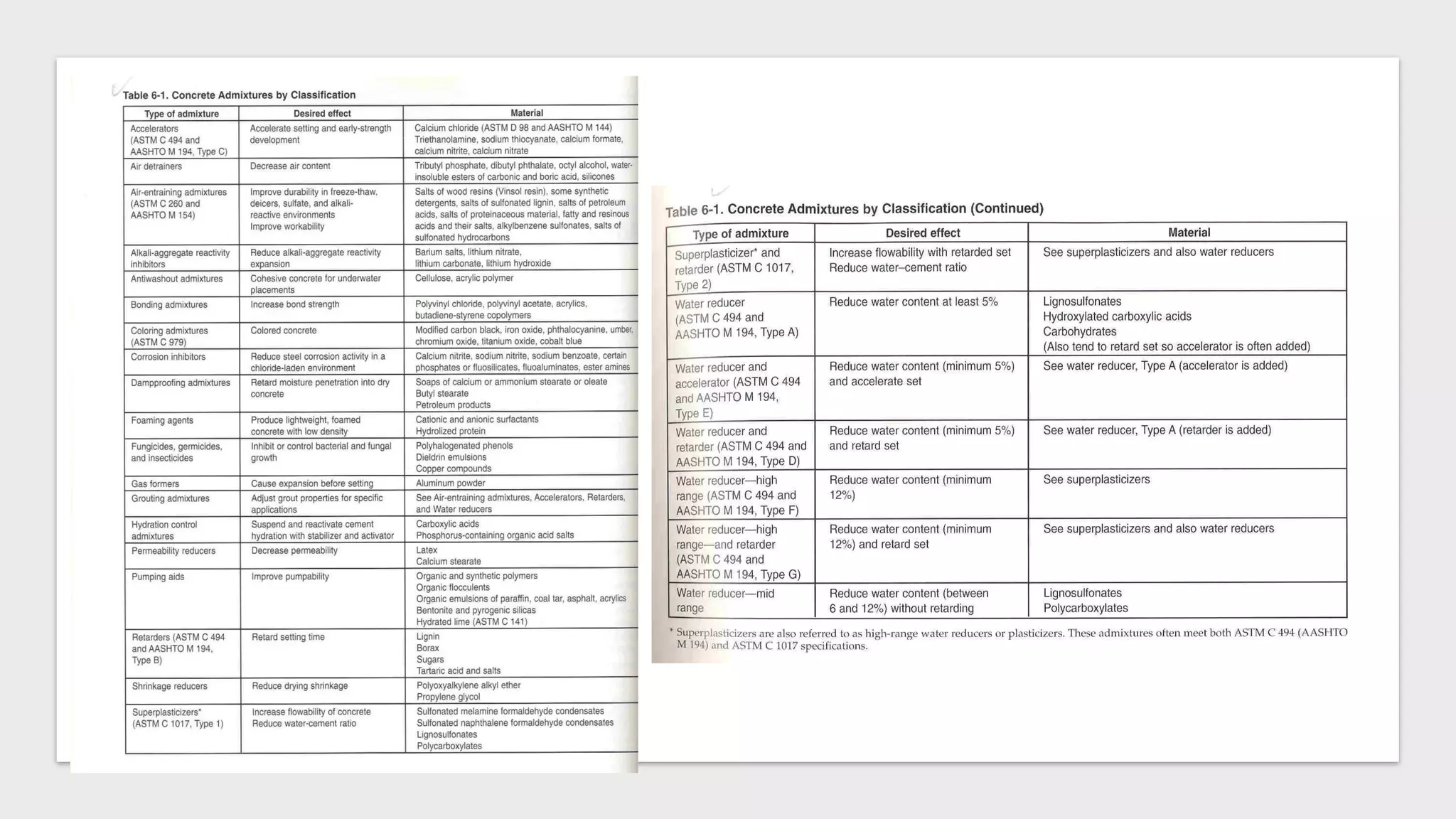

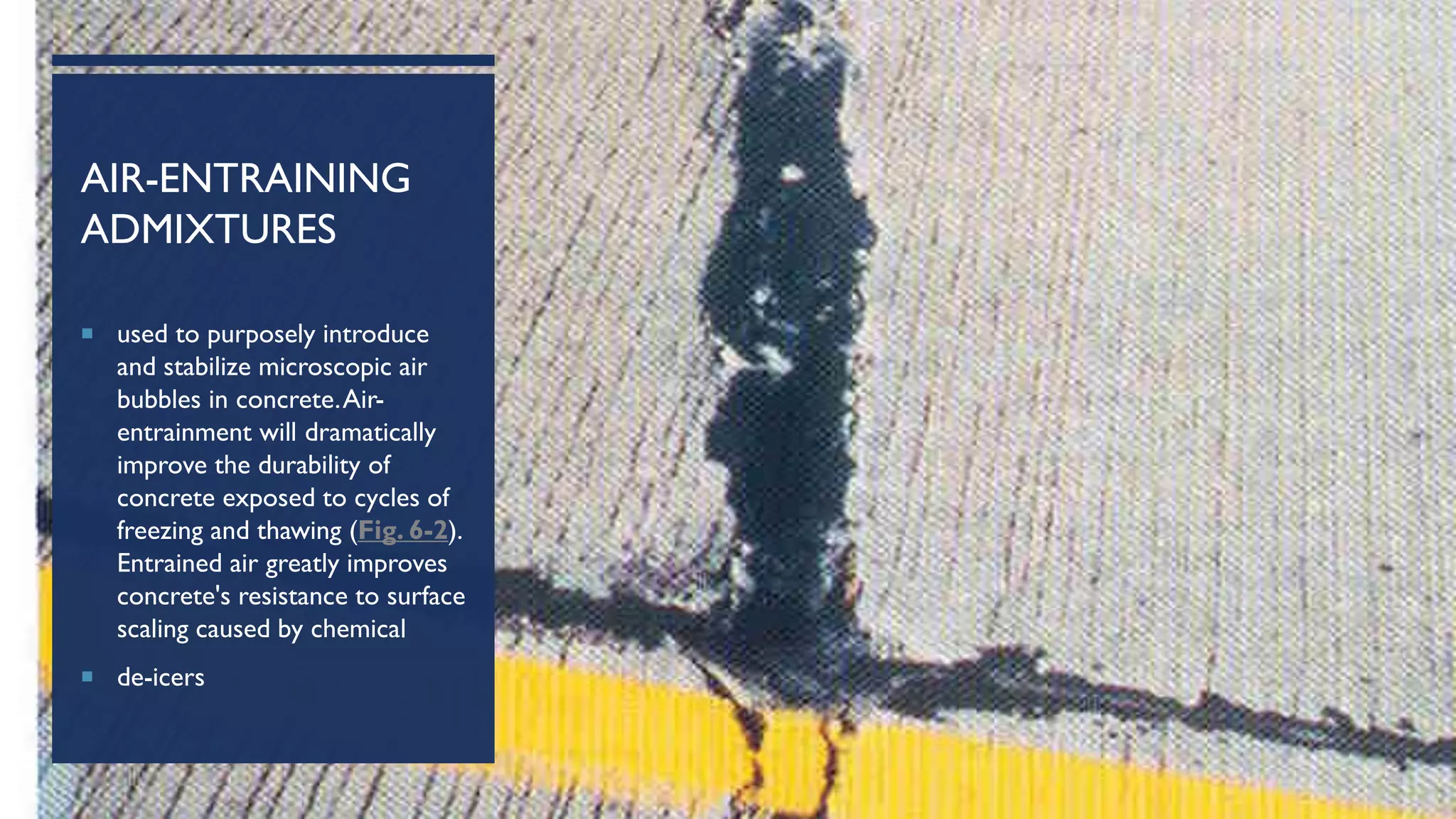

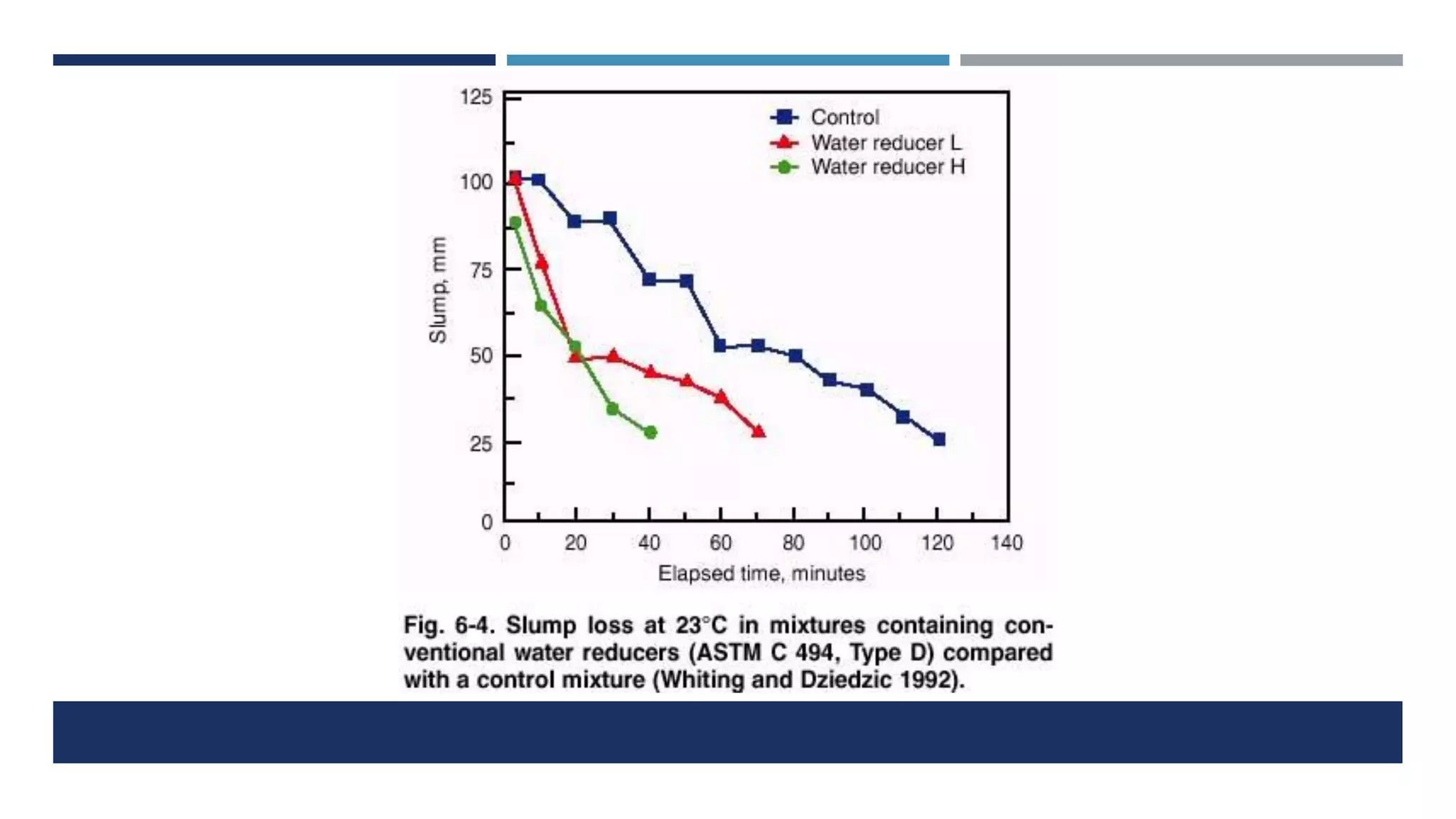

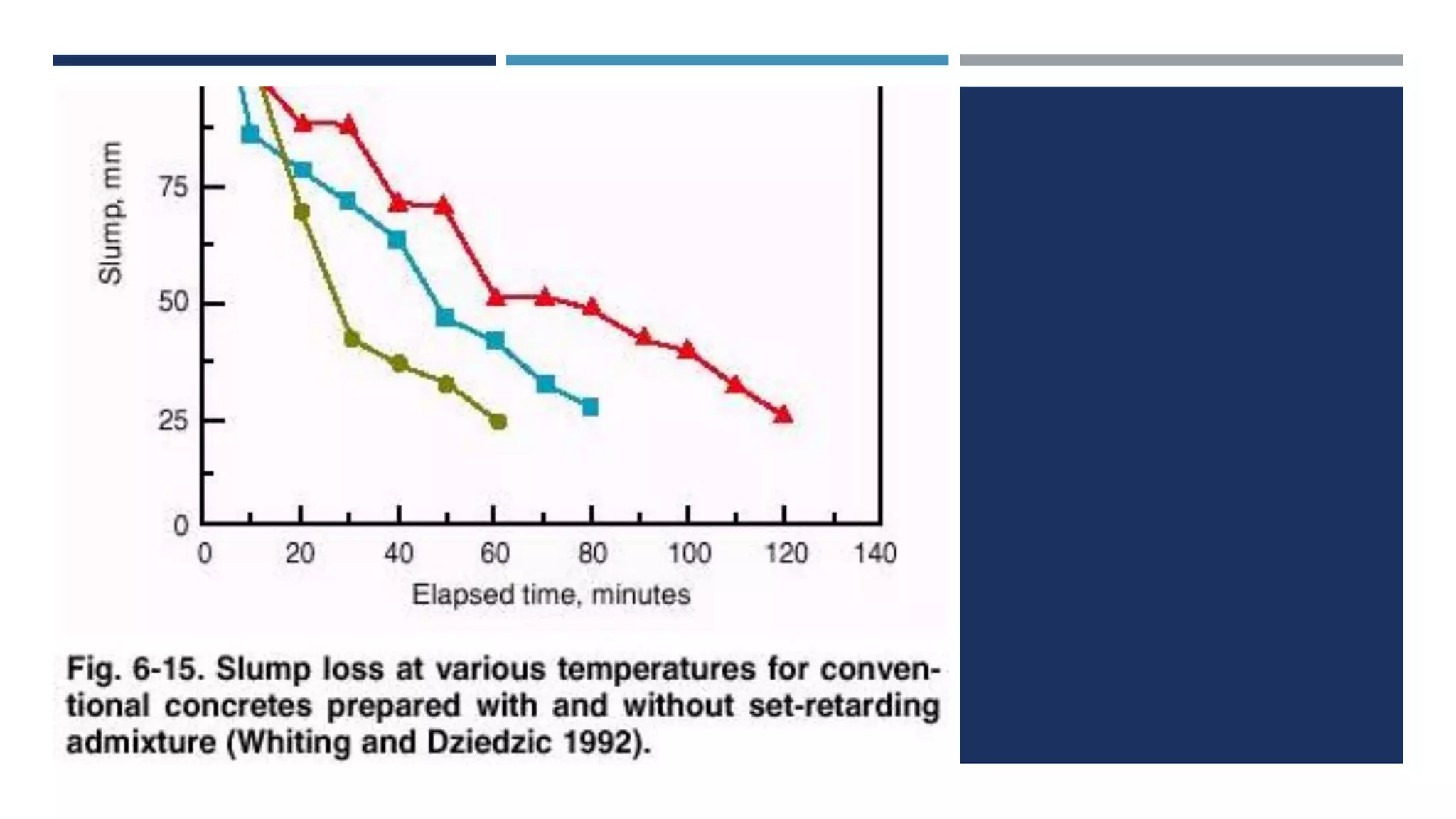

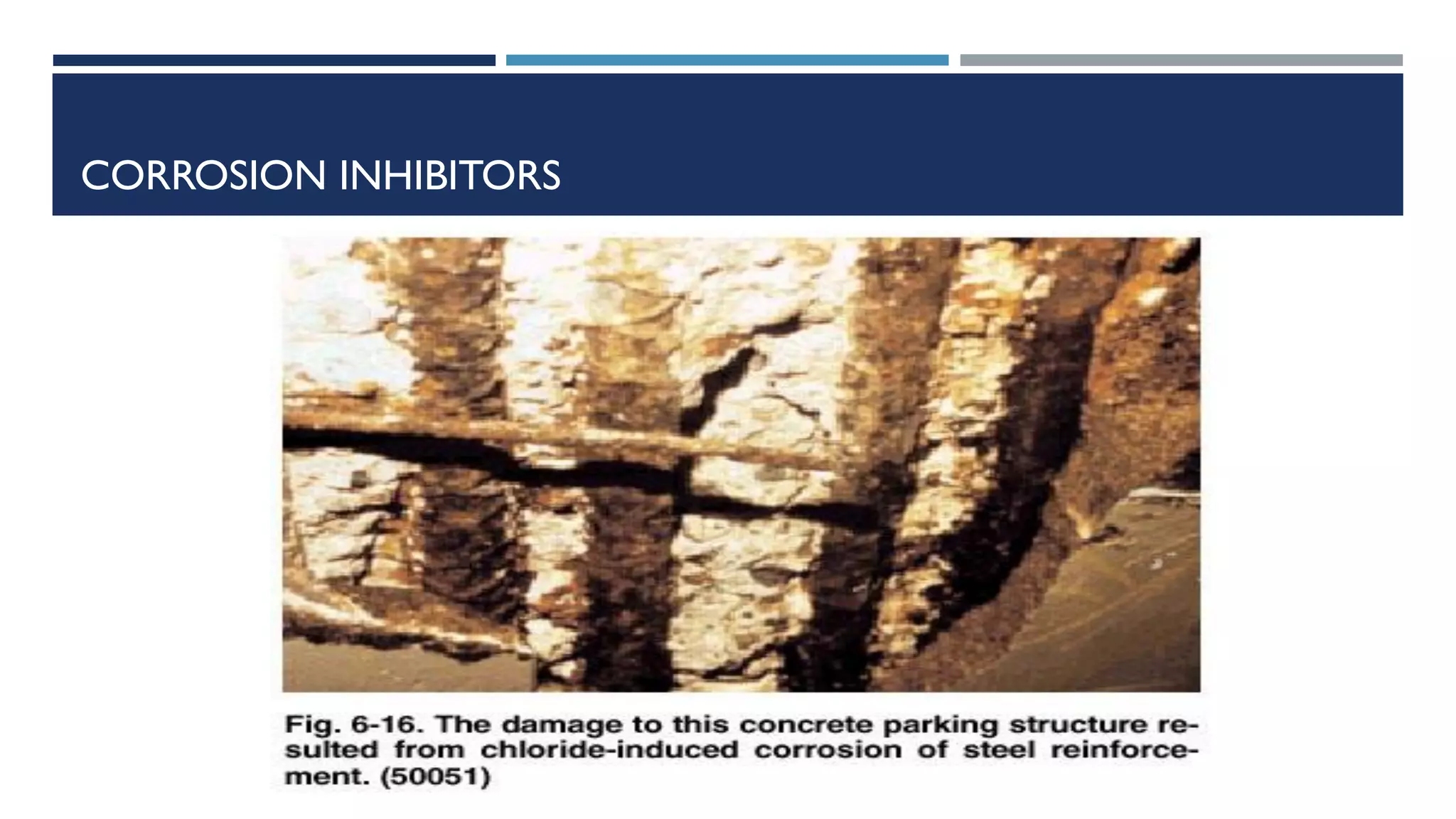

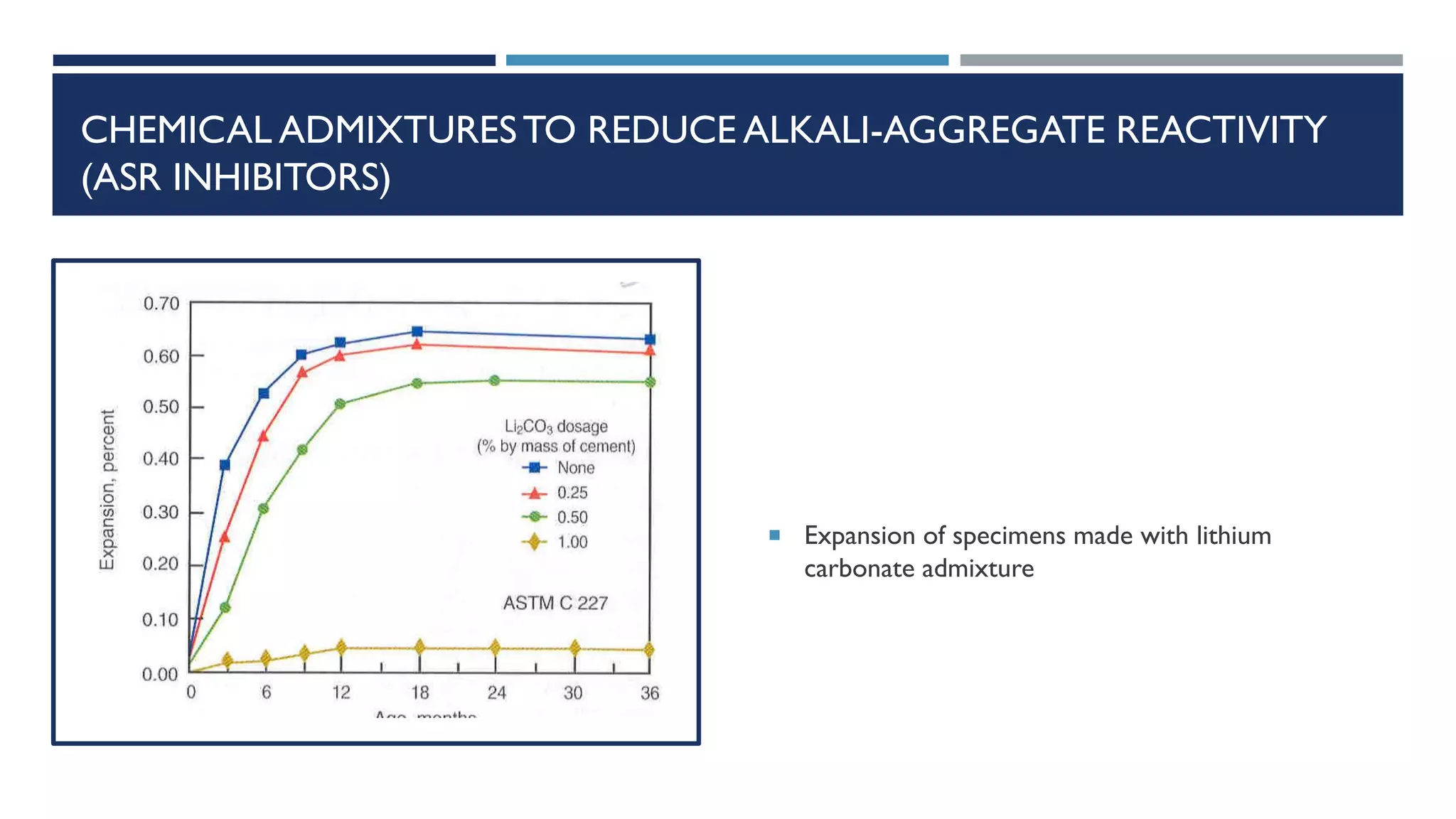

This document provides an introduction to reinforced concrete, including its components and advantages/disadvantages as a structural material. It discusses how concrete and steel work together compatibly in reinforced concrete. The key structural elements and design considerations like fitness for purpose, safety, economy and maintainability are outlined. Common types of Portland cement and admixtures like air-entraining, water-reducing, retarding and accelerating admixtures are described. Design codes and the historical background of reinforced concrete are also mentioned.