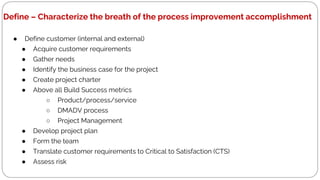

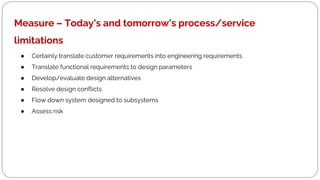

The DMADOV methodology is a Design for Six Sigma (DFSS) approach that involves 6 steps: Define, Measure, Analyze, Design, Optimize, and Verify. It is used to design new processes, products, or services. In the Define step, customer requirements are gathered. Measure involves translating requirements into engineering specifications. Analyze develops concepts and evaluates alternatives. Design generates the solution. Optimize refines the design using tools like experiments. Verify finalizes the design and implements controls. DMADOV forces consideration of optimization to refine the design.