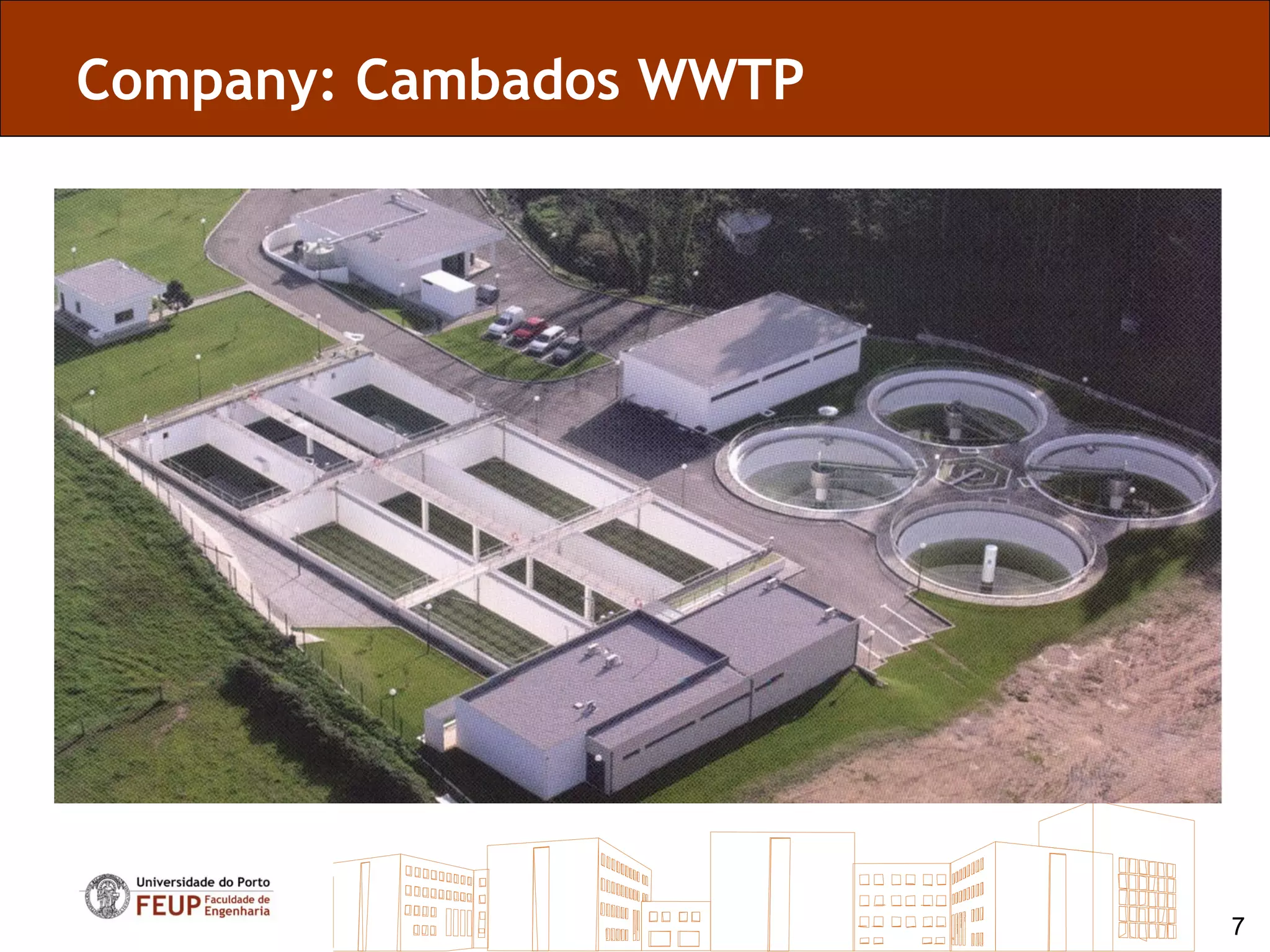

The document discusses the applications and evolution of Computational Fluid Dynamics (CFD) in various fields, particularly focusing on its role in wastewater treatment processes. It emphasizes the importance of CFD modeling in optimizing designs and improving performance by simulating hydrodynamics prior to implementation. The text highlights the current state of wastewater treatment technology and the potential cost and time savings associated with CFD-based designs.

![What is CFD?

The physical aspects of any fluid flow are governed by the

following three fundamental principles [1]:

Mass is conserved; Continuity equation

F = m·a (Newton’s second law); Momentum equation

Energy is conserved. Energy equation

2](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-2-2048.jpg)

![Evolution of CFD applications:

Figure 1 - Mapping of the Evolution of Patent Figure 2 - Mapping of the Evolution of

Applications filing [2] Scientifics Articles over time [2]

3](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-3-2048.jpg)

![CFD Applications:

CFD can be used in [3]:

• Aerospace & Defense

• Automotive

• Construction

• Health care

• Energy

• Chemical Processing

• Etc.

4](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-4-2048.jpg)

![Application of CFD in water waste treatment

Activated sludge process (ASP) plants includes the following stages

[3]:

Inlet works

Primary settlement

Activated sludge treatment

Secondary settlement

Tertiary treatment

CFD can be used to;

• Find capital cost savings,

• Achieve performance improvements,

• Energy savings.

5](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-5-2048.jpg)

![Application of CFD in water waste treatment [3]

6](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-6-2048.jpg)

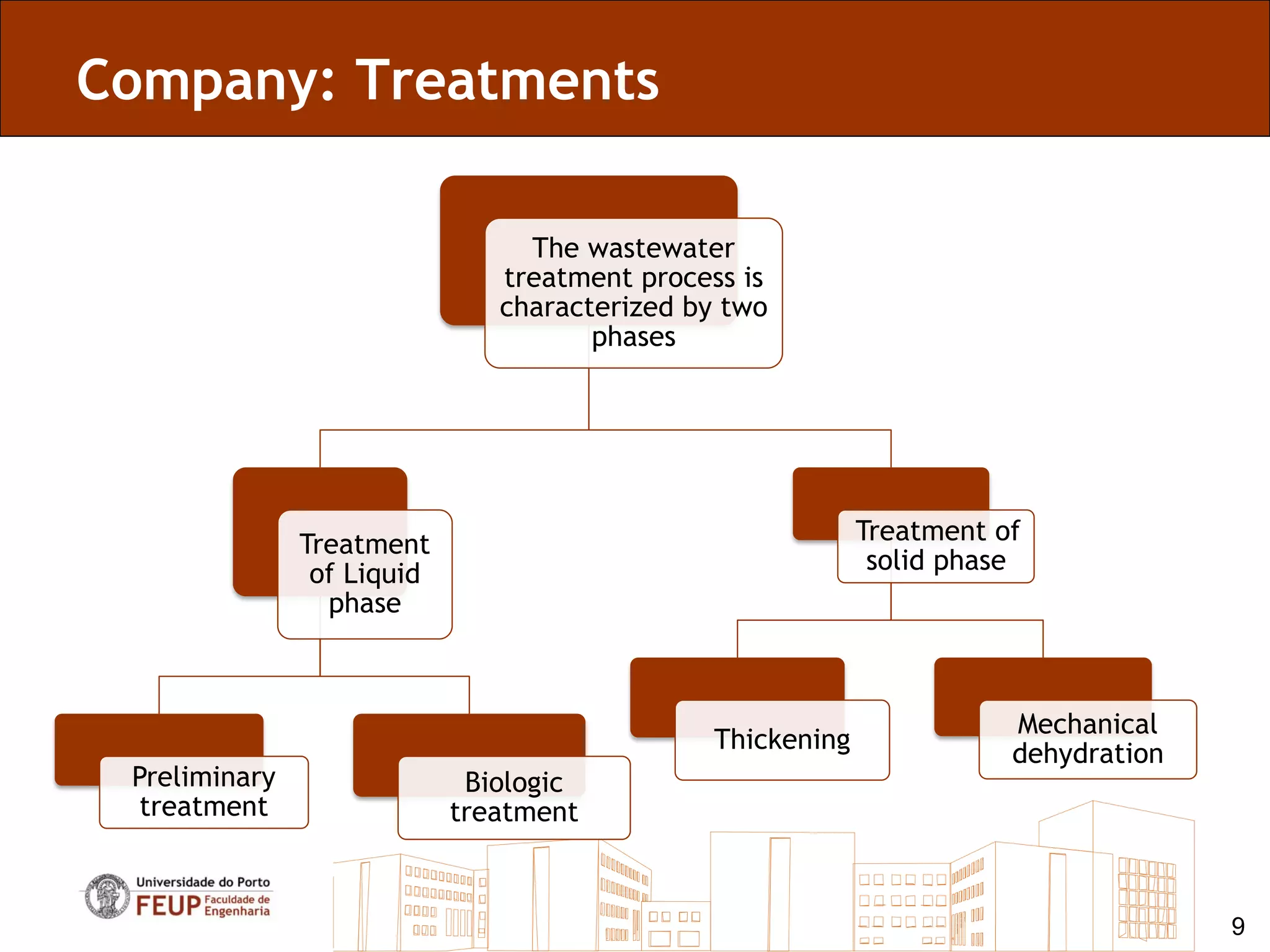

![Company: Treatments

• The decanted sludge is accumulated and then are returned

to the activated sludge tank. The decanted activated sludge,

when in excess, are send to a thickener tank to reduce the

moisture content. [4]

• After thickening, the sludge is dried, whose concentration

reaches 20% solids, and are destined for composing to the

Parada WWTP. [4]

10](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-10-2048.jpg)

![Current State of Design

Wastewater treatment vessels are sized according to required

pollutant removal: [5]

- Requires knowledge/assumptions of the flow regime (i.e.

hydrodynamics)

- Vessel configuration design to achieve flow type relies on

empirical correlations and heuristic techniques

11](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-11-2048.jpg)

![Hydrodynamics: Importance for Wastewater Treatment

The hydraulic behavior in an activated sludge tank, is of

fundamental importance for the efficiency of the process[6].

Hydraulic phenomena with negative effect on performance[6]:

-Short circuiting streams

-Dead volumes

12](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-12-2048.jpg)

![CFD: Alternatives

Models developed by the International Water Association are

useful tools for the process control. However, they are

unsuitable to model the influence of the reactor geometry; [7]

- Length/width ratio

- Presence of baffles

- Effluent inlet device

13](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-13-2048.jpg)

![CFD: Alternatives

Full-scale tracer tests are very informative when investigating

hydraulic situations in activated sludge tanks however [6];

-It claims a lot of personal

-And mean residence times are in order of days

So it becomes impracticable

14](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-14-2048.jpg)

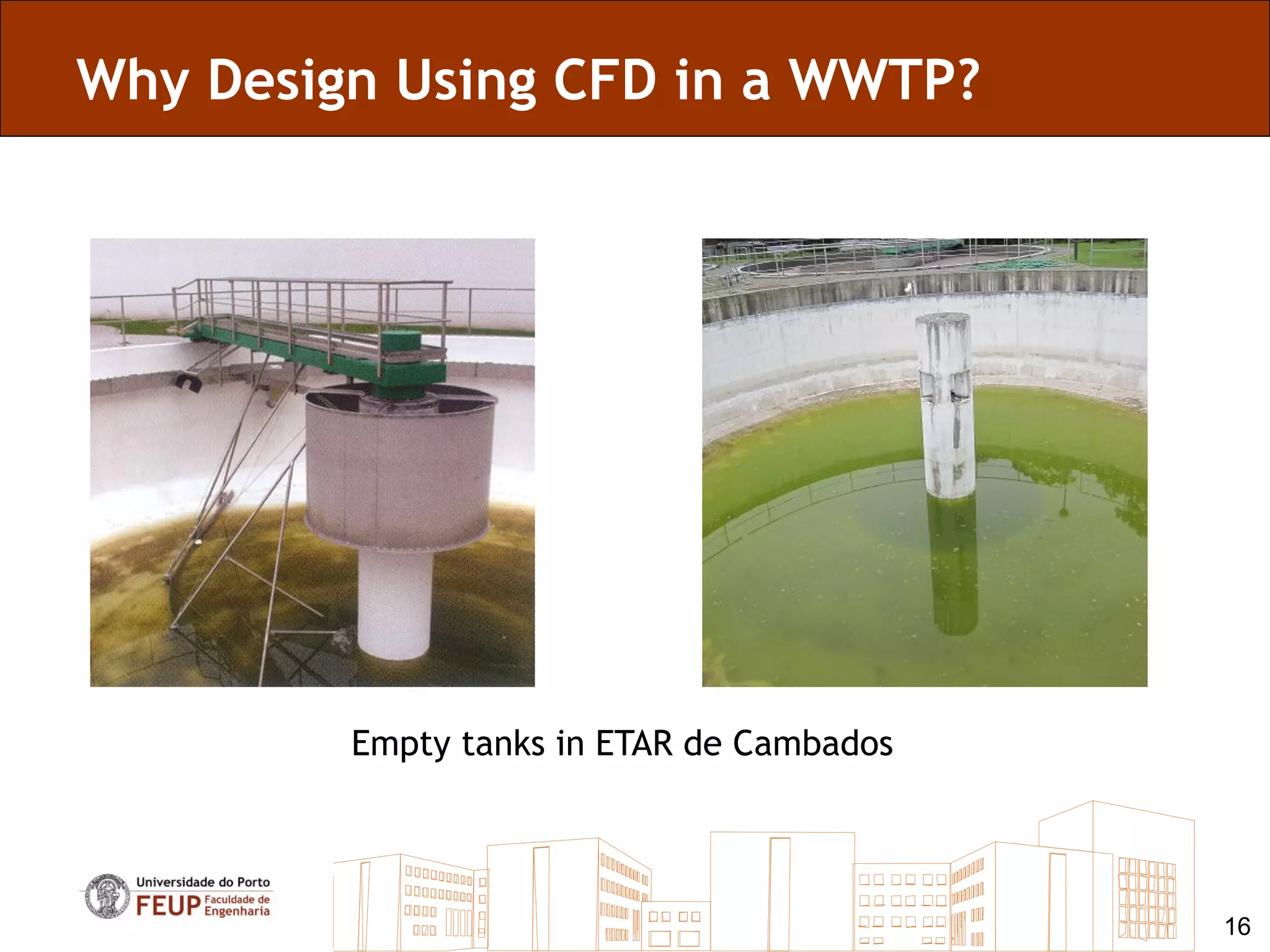

![Why Design Using CFD in a WWTP?

A CFD model can simulate the hydrodynamics of a design before

implementation [8]:

- Reducing lead-up times and costs

- Ultimately lead to optimization of reactor configuration

15](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-15-2048.jpg)

![References

[1] Anderson, Jr., John D.; Computational Fluid Dynamics. ISBN: 0-

07-113210-4

[2] Islabão, G. et al (2010). Technological Trends in CFD Applications.

Journal of Technologyl, Managment and Innovation, 76-83.

[3] http://www.ansys.com/

[4] http://www.ambiente.maiadigital.pt

[5] L. Benedetti et al (2006). Benchmarking of WWTP design by

assessing costs,. Water Science & Technology, 95–102.

18](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-20-2048.jpg)

![References

[6] Kjellstrand R. et al (2005) Short Circuiting in a Denitryfying

Activated Sludge Tank. Water Science & Technology, Vol. 52, No. 10-

11, pp 79-87, IWA

[7] Moullec, Y. L. (2010). CFD simulation of the hydrodynamics and

reactions in an activated sludge channel. Chemical Engineering

Science, 492 - 498.

[8] Brannock, Matthew (2003). Computational fluid dynamics tools

for the design of mixed anoxic wastewater treatment vessels PhD

Thesis, School of Engineering, The University of Queensland.

19](https://image.slidesharecdn.com/computationalfluiddynamicsinwwtp-120417174949-phpapp02/75/Computational-fluid-dynamics-in-water-waste-treatment-plants-21-2048.jpg)