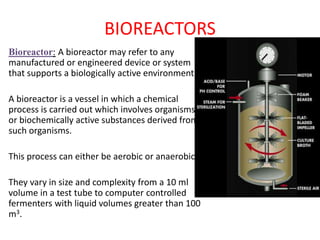

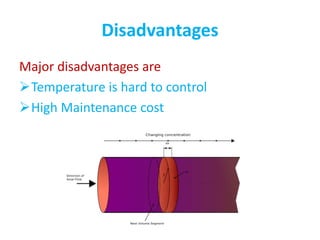

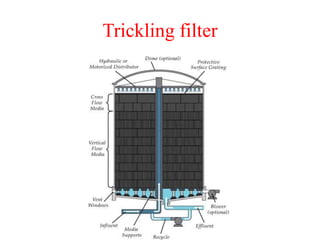

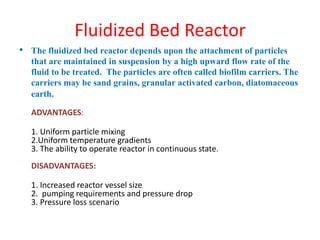

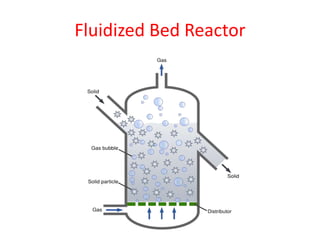

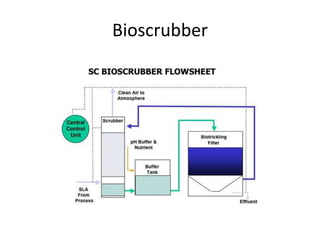

This document discusses different types of bioreactors. It begins by defining a bioreactor as an engineered device that supports a biologically active environment. It then classifies bioreactors as either suspended growth or biofilm reactors. The main types of bioreactors discussed are batch, continuous stirred-tank (CSTR), plug flow, packed bed, fluidized bed, and trickling filters. Applications mentioned include waste water treatment, food production, and reducing air pollutants. The document provides details on the operation and uses of these various bioreactor configurations.