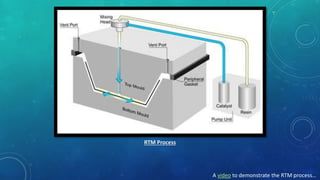

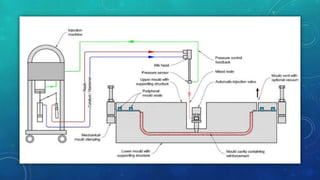

This document discusses out of autoclave composite manufacturing and resin transfer molding (RTM) as alternative processes to traditional autoclave curing. RTM involves placing fiber reinforcement in a closed mold and injecting resin under pressure and heat without an autoclave. The resin cures as it flows through the mold. RTM produces high strength, lightweight composite parts with complex shapes. It is commonly used for aircraft, boat, and wind turbine components. The document provides overviews of RTM and out of autoclave processes, companies that use RTM, benefits, applications, and references for further information.