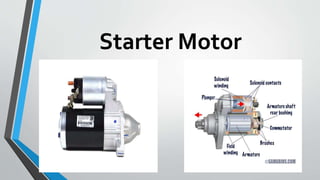

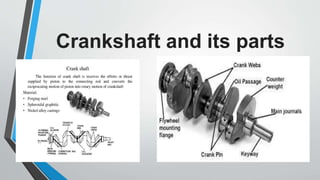

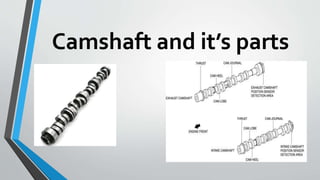

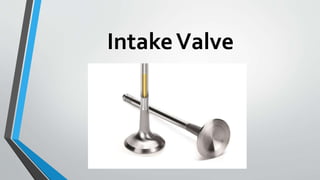

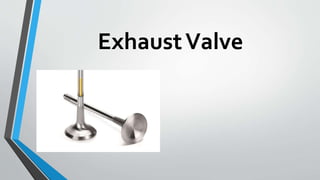

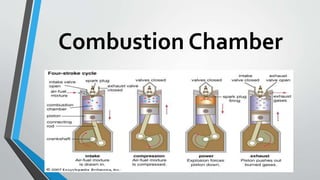

The document provides details on the main mechanical components of an internal combustion engine. It describes the key internal parts, like the cylinder head, engine block, pistons, valves, camshaft and crankshaft. It also outlines important external components, such as the starter motor, alternator, radiator, and fuel pump. Specific parts are called out for gasoline engines, like the carburetor and distributor, as well as diesel engines, including the injection pump, fuel injectors and glow plugs.