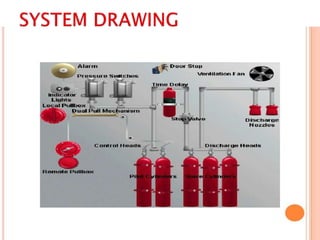

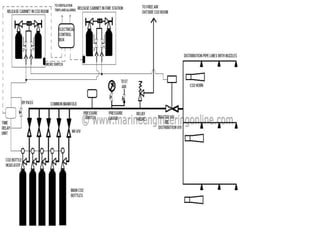

The CO2 flooding system releases carbon dioxide into protected spaces on ships to extinguish fires. CO2 cylinders located in a separate room contain liquid CO2 that is directed through pipes to nozzles in protected spaces when manually activated. CO2 displaces oxygen in the air which prevents combustion from occurring, smothering the fire. It is effective on various fire types and leaves no residue, but is also highly asphyxiating to humans if inhaled in high concentrations.