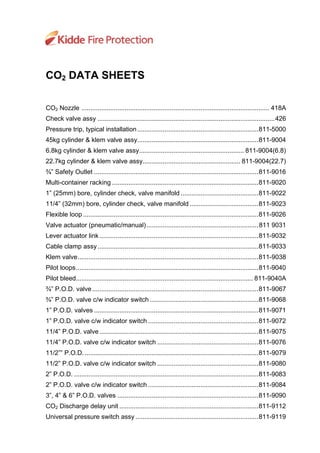

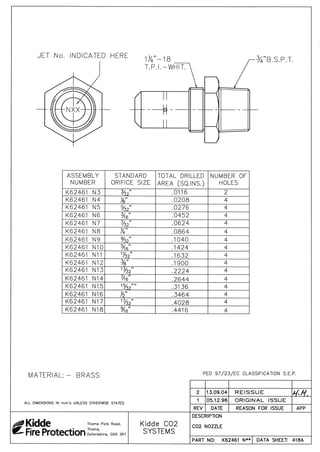

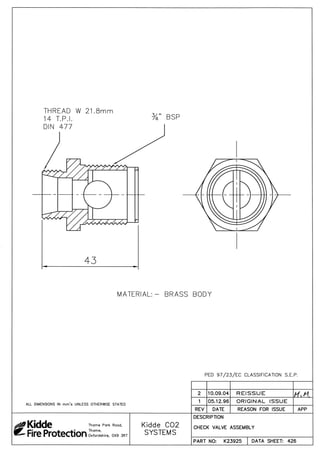

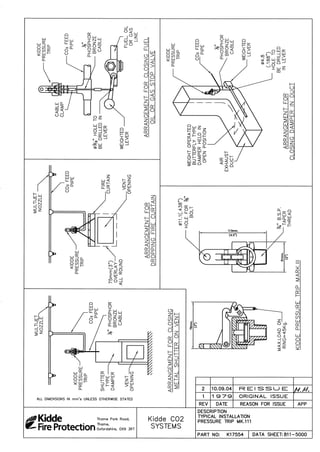

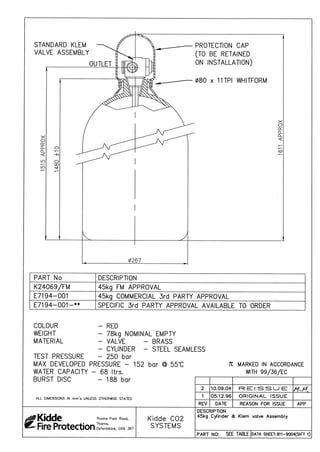

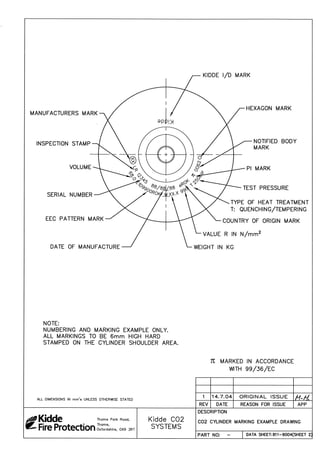

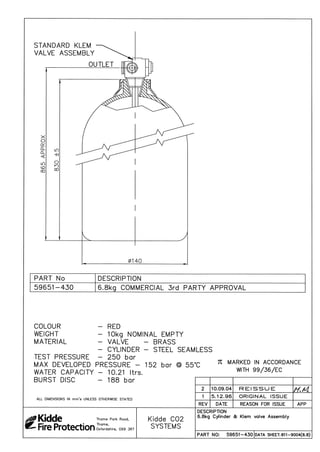

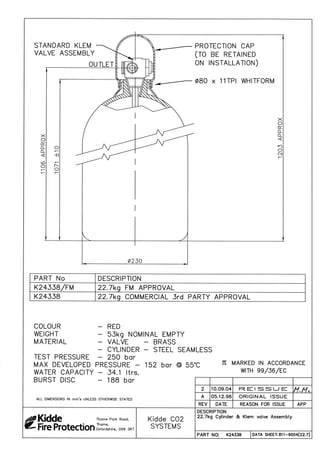

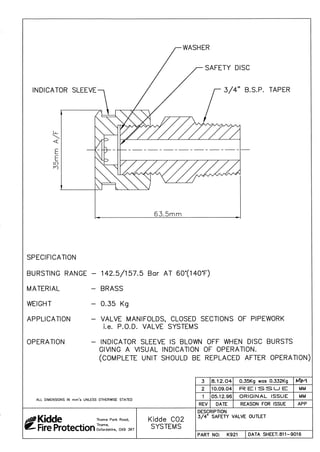

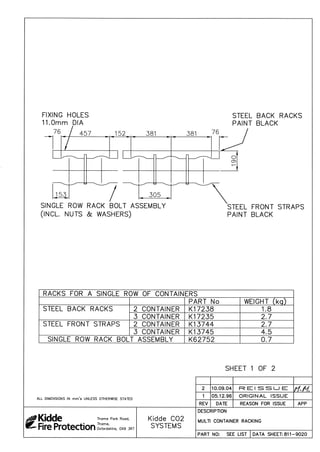

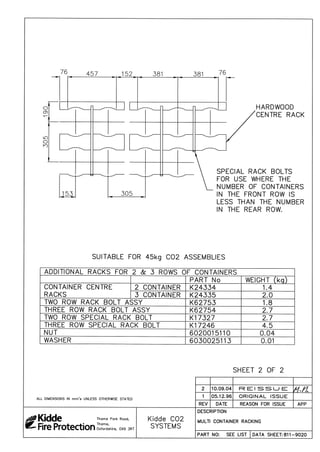

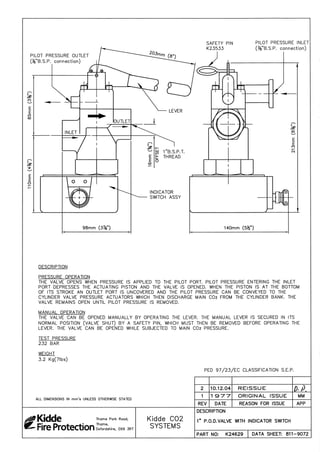

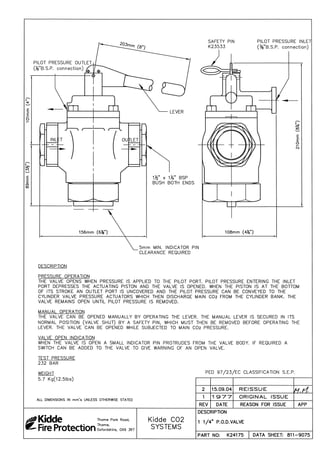

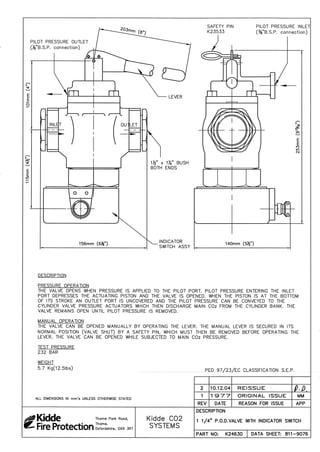

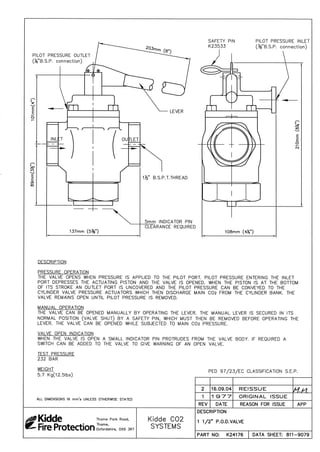

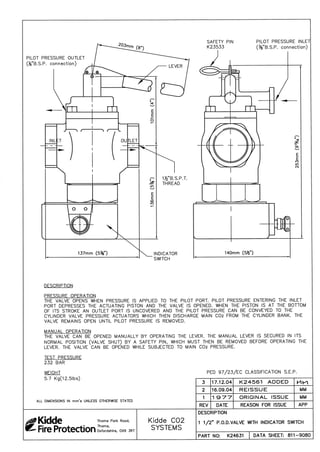

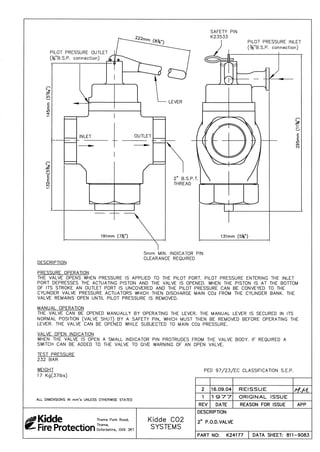

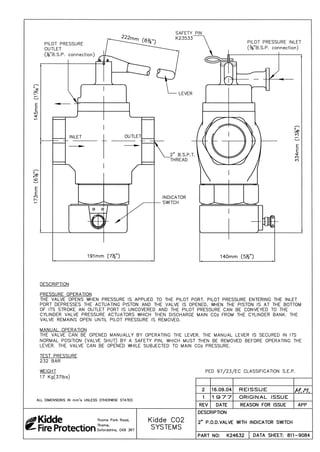

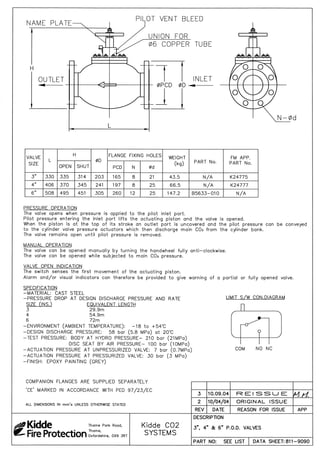

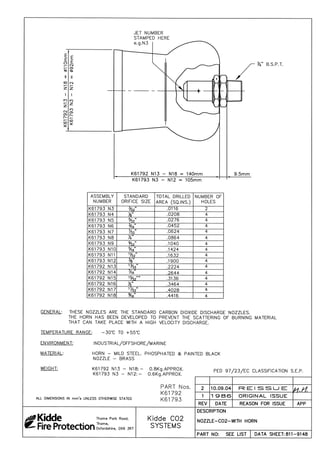

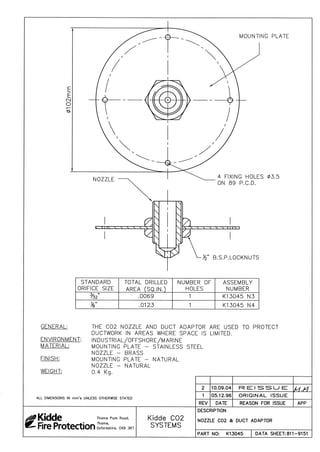

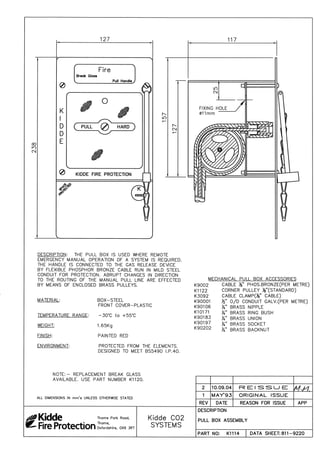

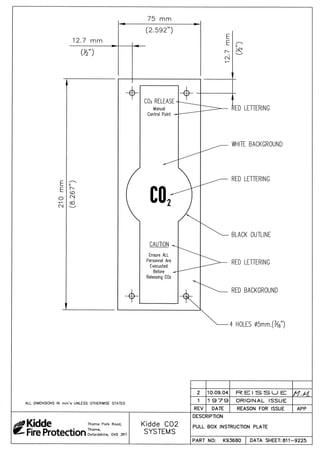

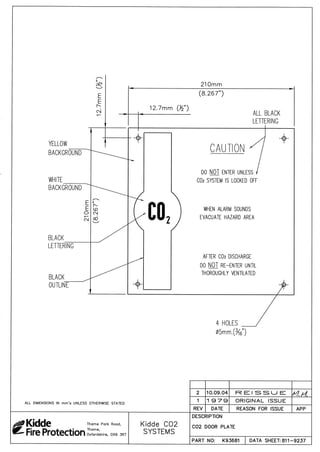

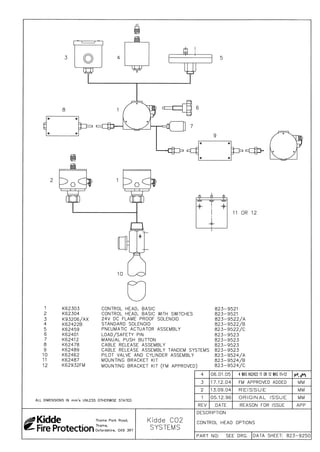

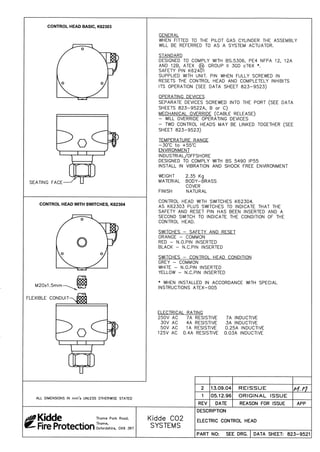

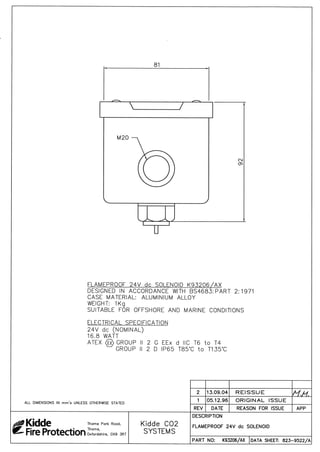

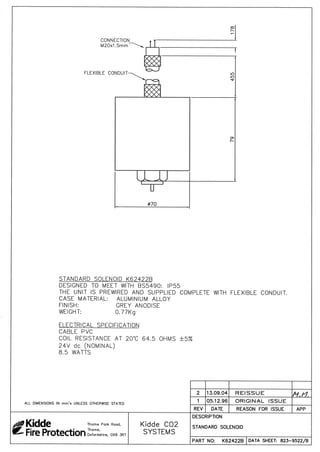

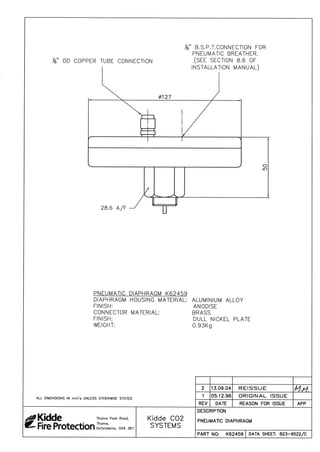

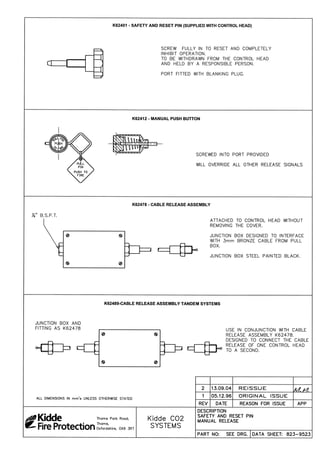

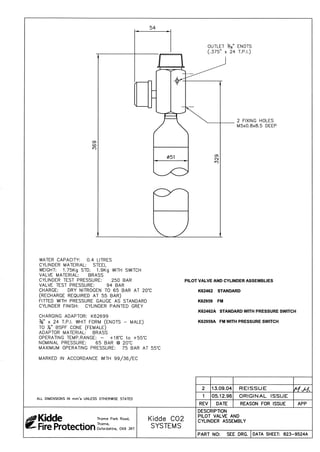

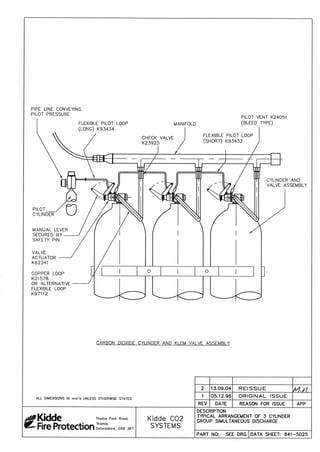

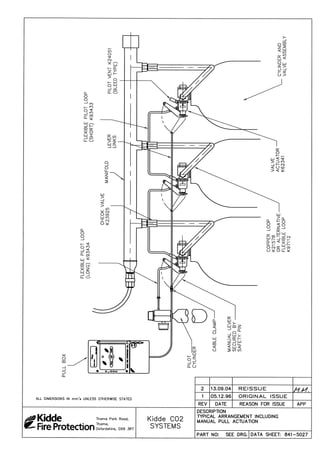

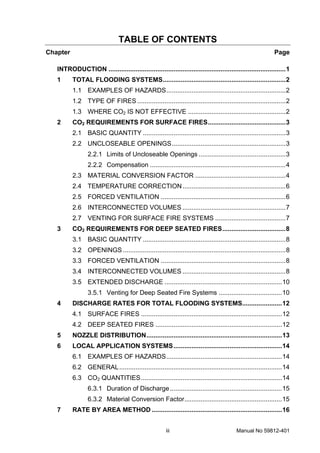

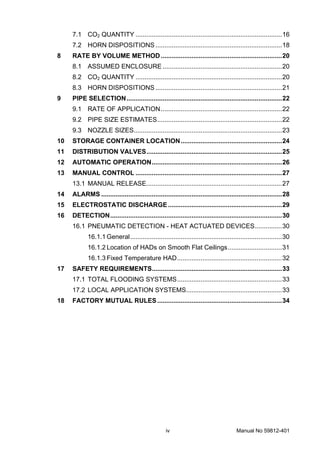

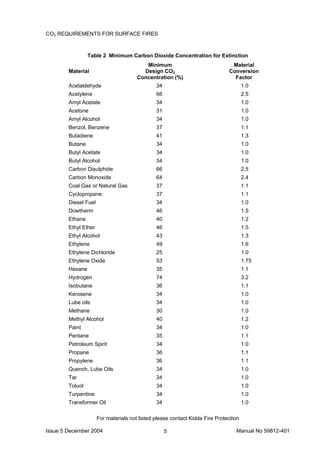

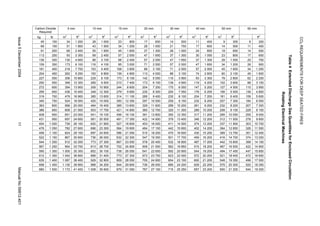

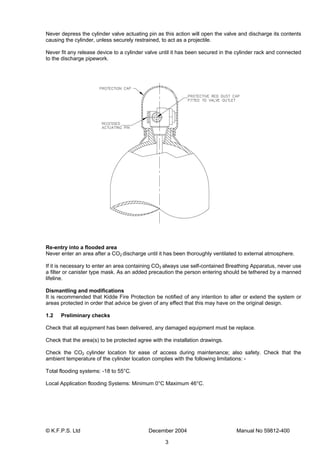

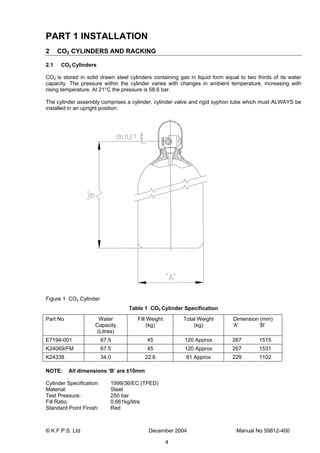

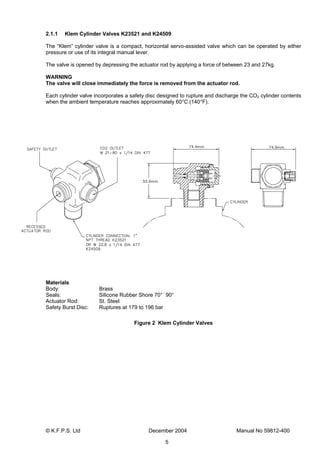

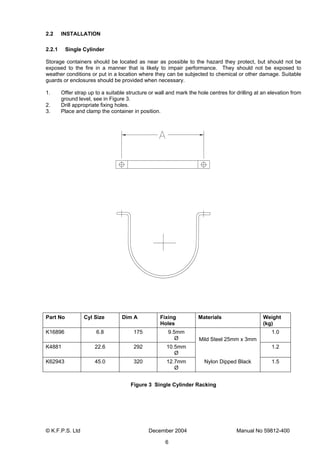

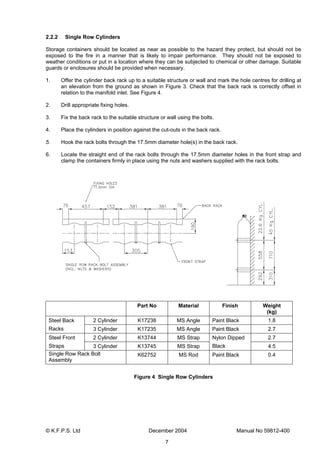

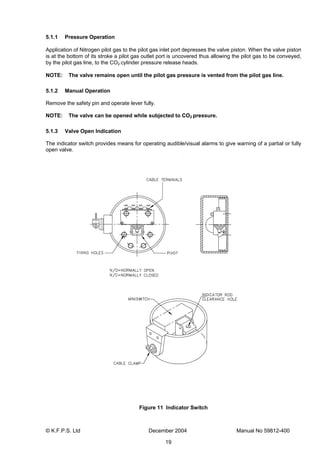

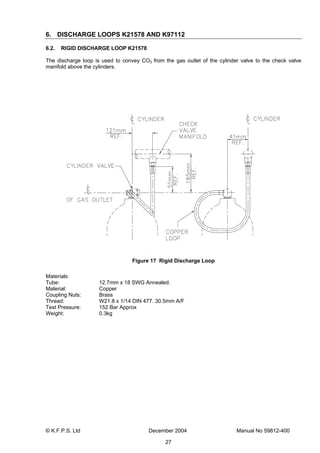

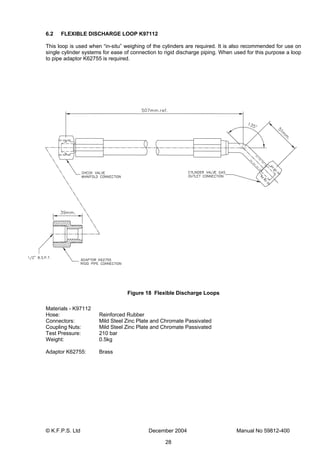

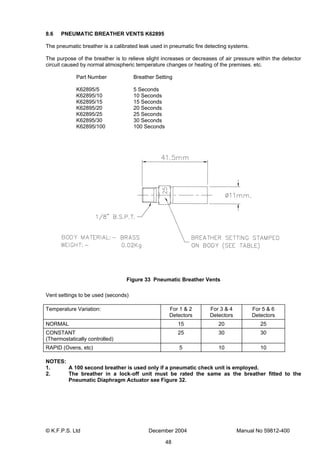

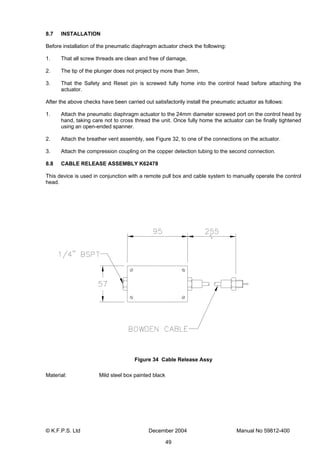

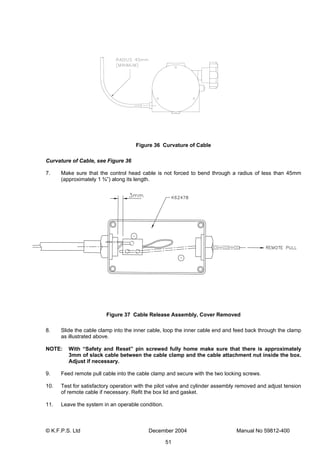

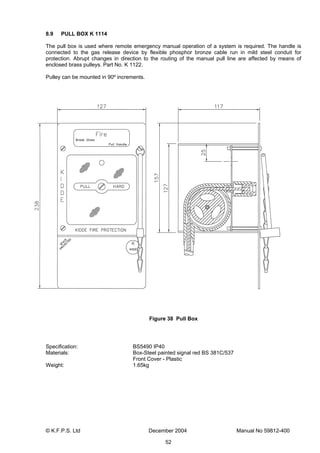

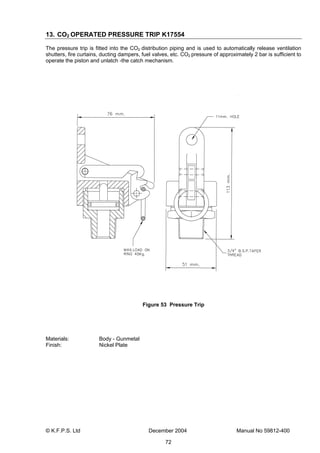

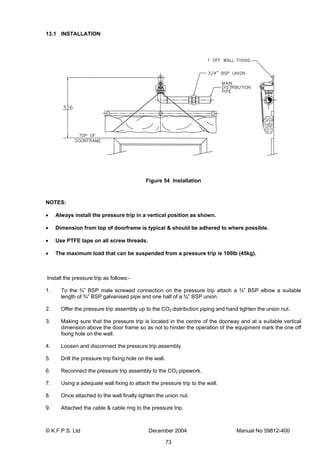

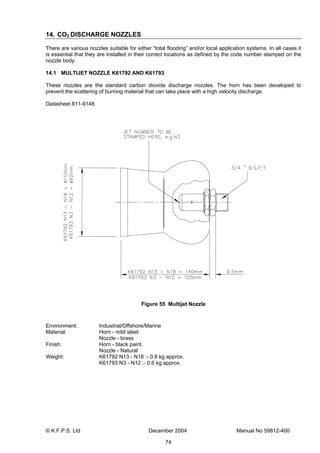

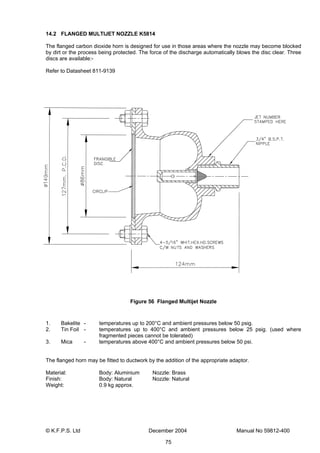

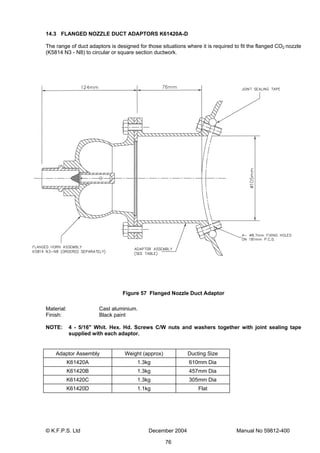

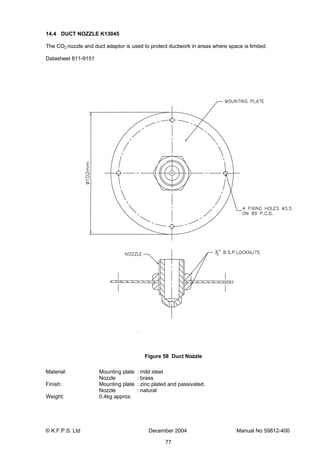

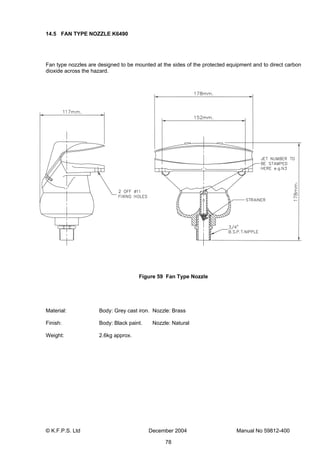

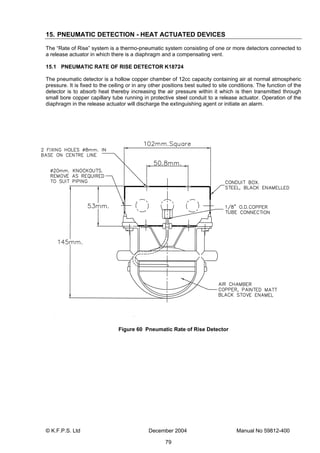

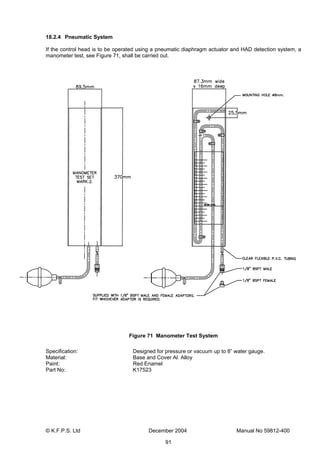

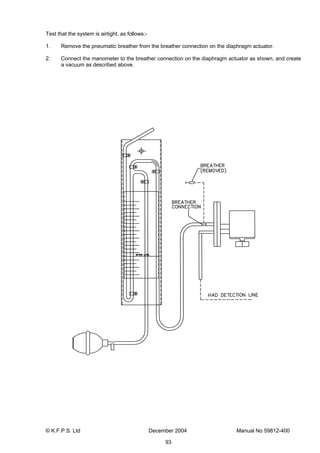

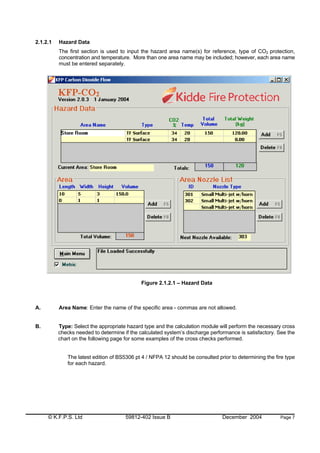

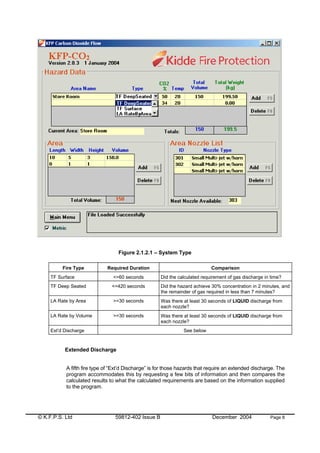

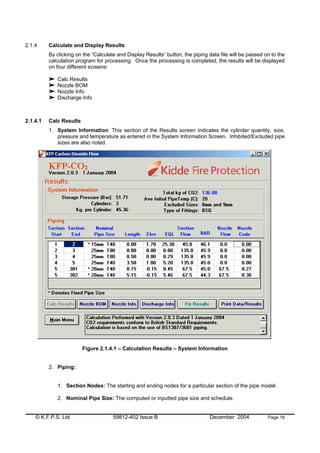

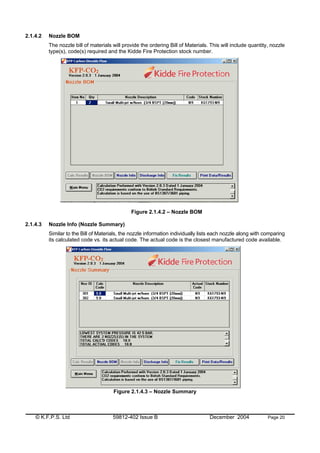

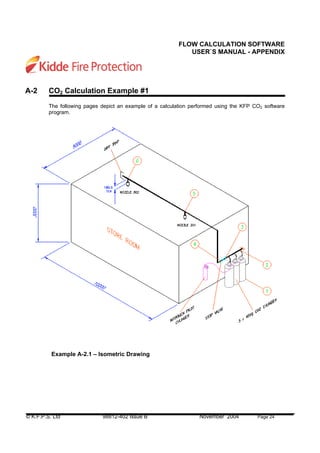

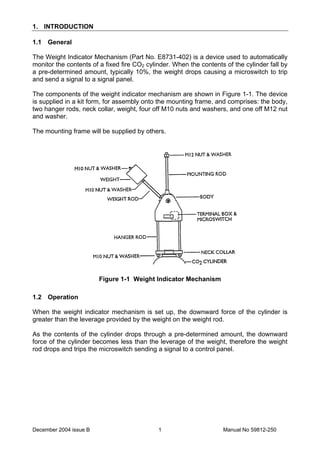

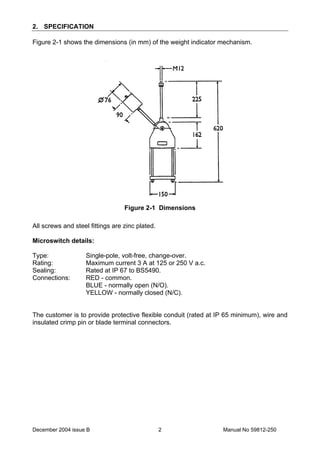

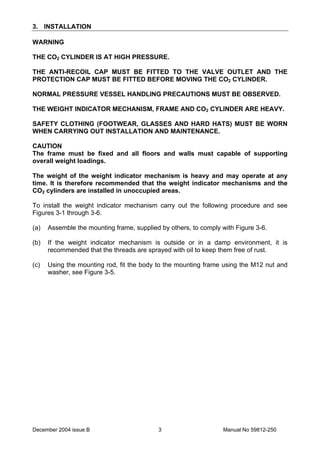

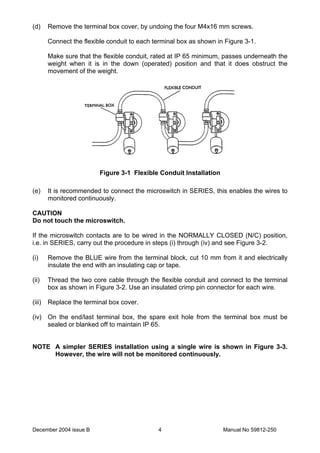

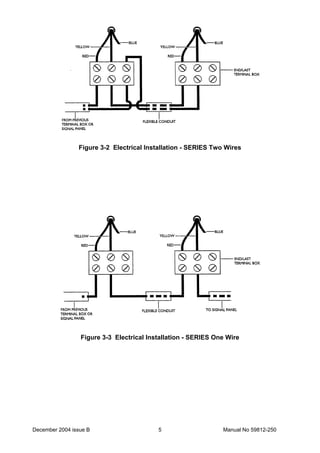

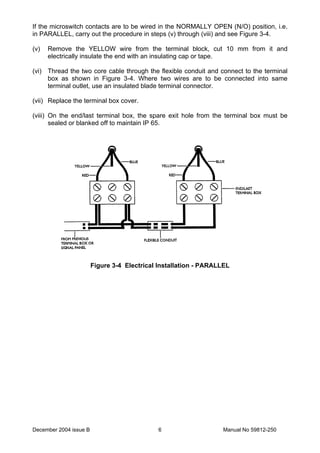

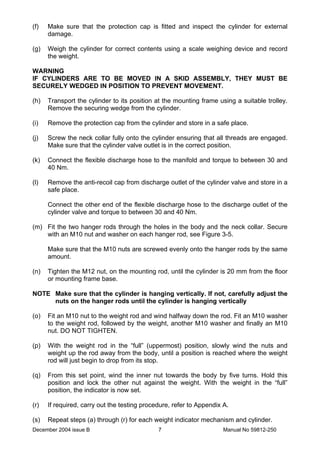

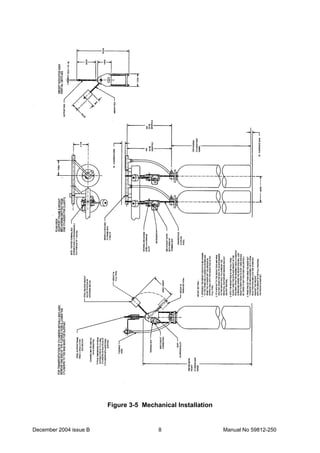

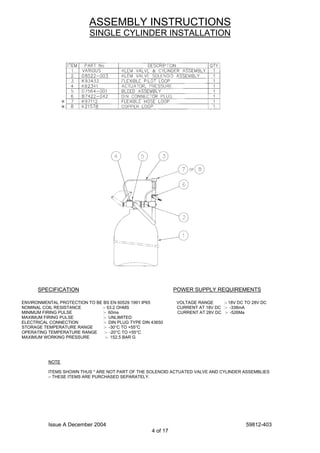

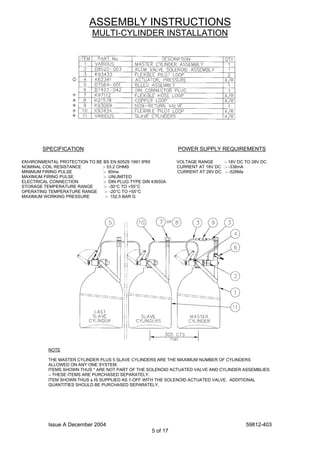

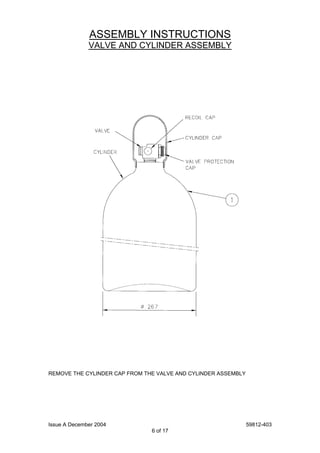

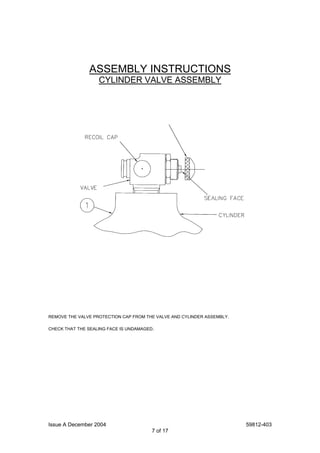

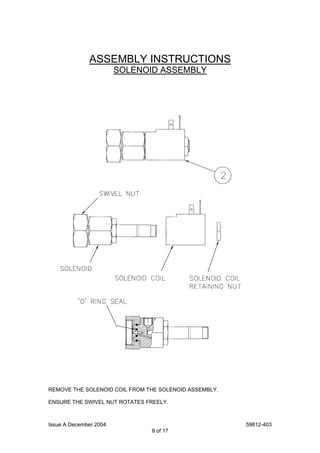

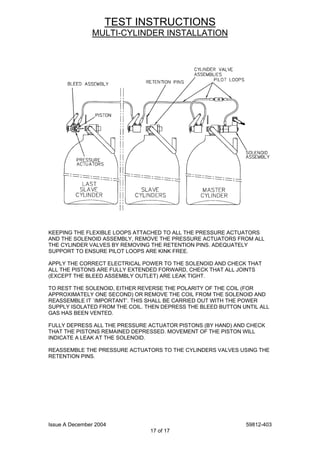

This document contains a product manual for a high pressure carbon dioxide fire suppression system. It includes 10 sections that cover specifications, data sheets, design manuals, installation manuals, software manuals, weight monitoring systems, solenoid valves, owner's manuals, approvals, and information bulletins. The document provides detailed information on the components, design, installation, and operation of Kidde carbon dioxide fire suppression systems.