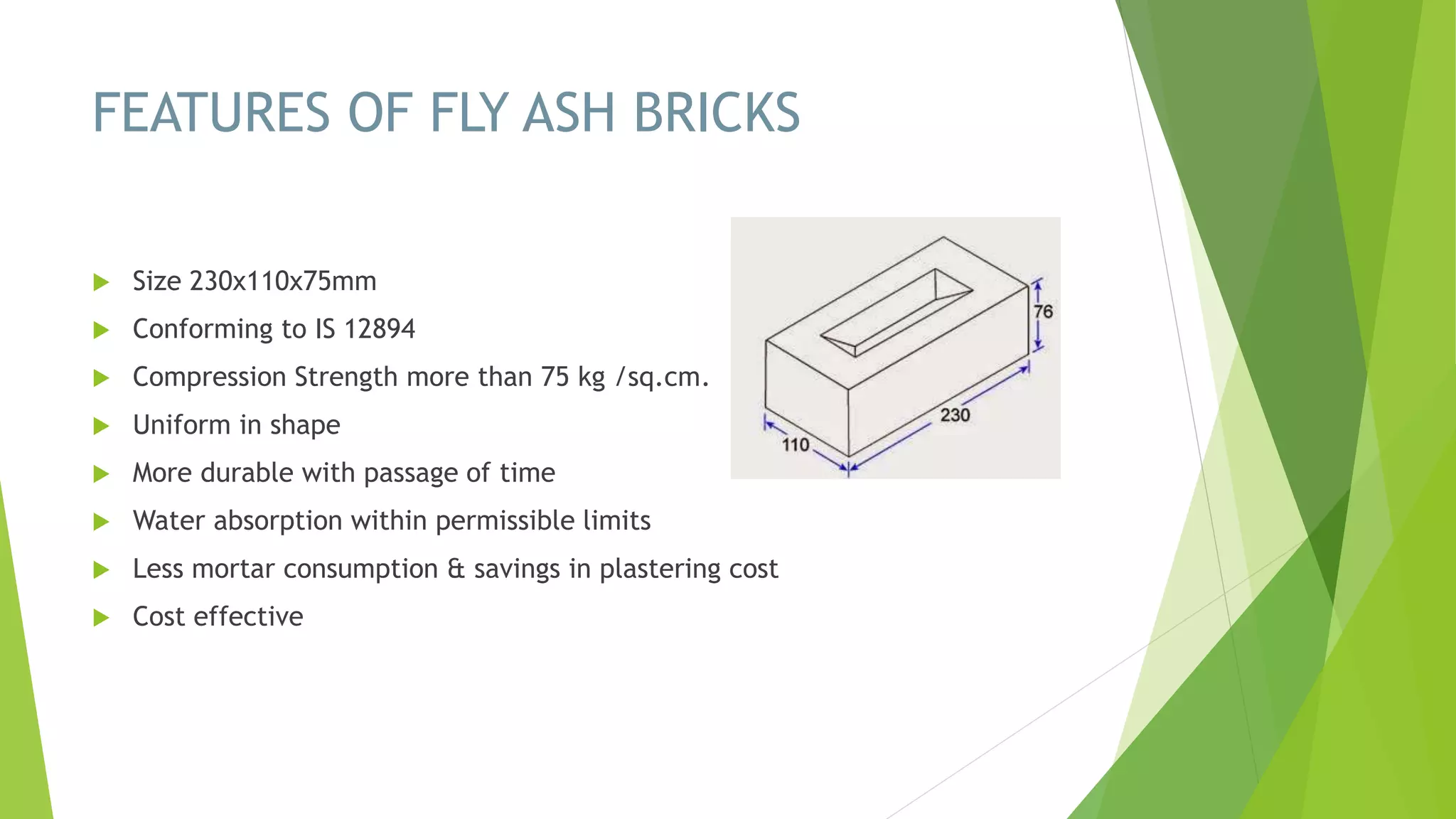

The document discusses fly ash, a byproduct of coal combustion, and its application in the manufacturing of fly ash bricks, which are lighter and stronger than traditional clay bricks. It outlines the advantages of fly ash bricks, such as lower water absorption and cost-effectiveness, while also noting the importance of using high-quality fly ash to avoid negative impacts on building structures. The document emphasizes the environmental benefits and efficiency gains associated with using fly ash bricks in construction.