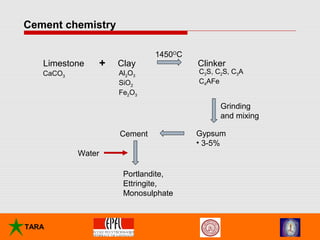

The document outlines the development of low carbon cement, emphasizing the need to address misconceptions about the environmental impact of cement and concrete, which account for 5-8% of global CO2 emissions. It discusses the Indian cement industry's efficiency and projected growth, highlighting concerns such as energy consumption and raw material availability. The low carbon cement project involves research, technology application, and stakeholder collaboration to reduce emissions and improve sustainability in the industry.