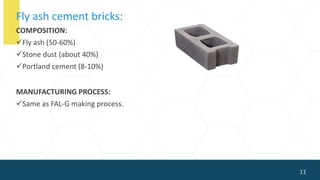

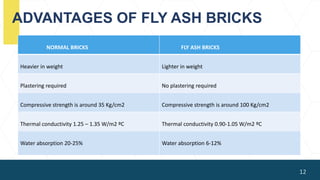

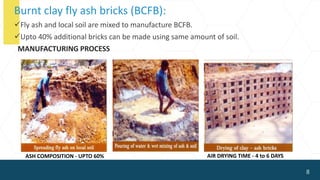

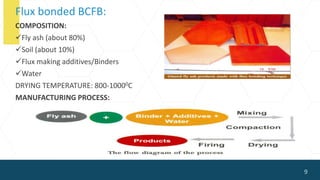

This document discusses fly ash bricks as an alternative to traditional clay bricks. Fly ash is a byproduct of coal combustion in power plants, and large amounts of fly ash are produced annually in India. Fly ash bricks have several advantages over clay bricks - they are lighter, stronger, and more insulative. Various types of fly ash bricks are described, including those made from mixing fly ash with soil or adding lime, gypsum or cement. Fly ash bricks can help utilize a waste product while providing a more sustainable building material.

![SUBMITTED BY :

AVINASH

JAISWAL

[CSJMA14001390195]

B.TECH,

IVth year

[CHEMICAL ENGINEERING]

FLY ASH BRICKS](https://image.slidesharecdn.com/flyashbricks-195-180426153619/75/Fly-ash-bricks-195-1-2048.jpg)

![Fly ash lime gypsum bricks (FAL-G):

COMPOSITION:

Fly ash (50-65%)

Hydrated lime (8-12%)

Stone dust (20-30%)

Gypsum (5%)

MANUFACTURING PROCESS:

10

[1 - 2 DAYS] [15 - 21 DAYS]](https://image.slidesharecdn.com/flyashbricks-195-180426153619/85/Fly-ash-bricks-195-11-320.jpg)