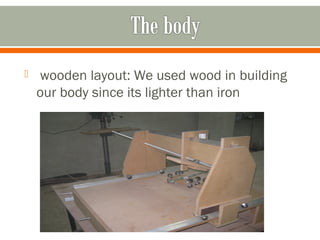

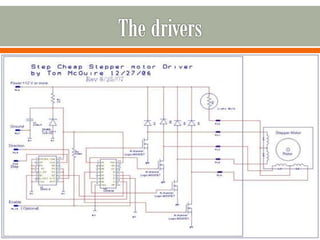

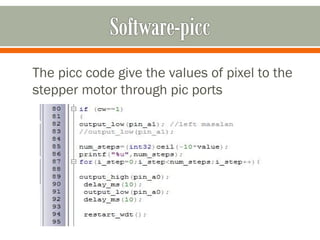

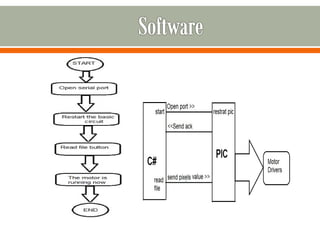

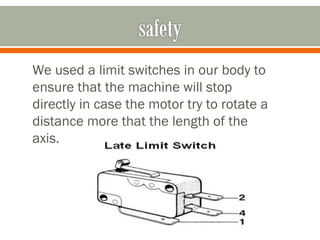

The document discusses a CNC machine created by Rania hasan and Enas hamadneh. It describes how numerical control allows a machine to operate automatically based on coded instructions. The CNC machine uses a PIC 18 controller and stepper motors to move in the X, Y, and Z axes according to G-code instructions parsed from a program. Safety features like limit switches ensure the machine stops if axes are exceeded. The goal was to make an inexpensive and fast CNC machine capable of drilling designs into wood.