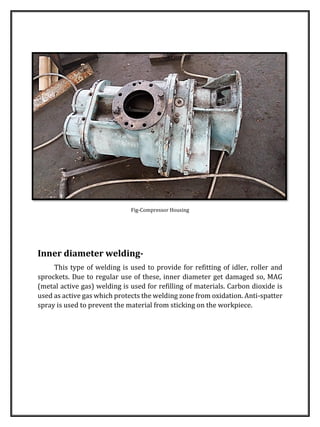

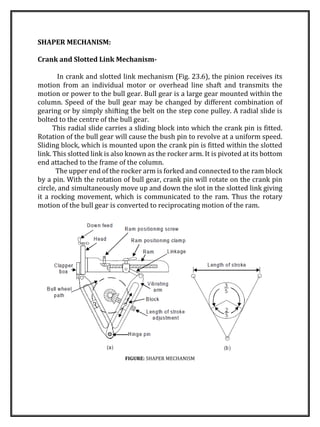

This document provides a summary of the author's summer training report on workshop practices and mechanical activities at the Central Workshop in Gevra. It describes several mechanical shops visited, including the electrical repair shop, engine shop, heavy repair shop, and machine shop. The electrical repair shop repairs AC/DC motors and transformers. The engine shop performs maintenance on various engine parts and systems. The heavy repair shop repairs large equipment like magnetorques and compressors. The machine shop contains lathe and shaper machines used for machining cylindrical parts.