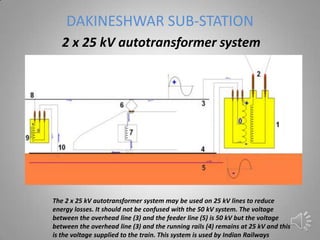

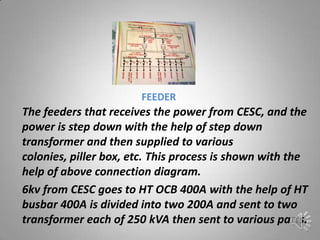

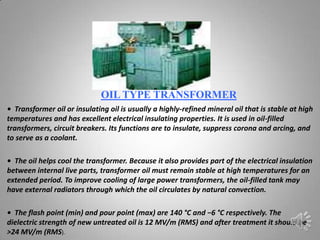

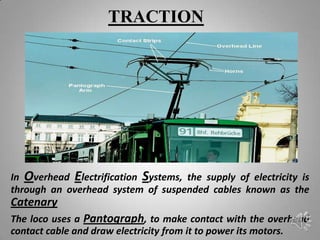

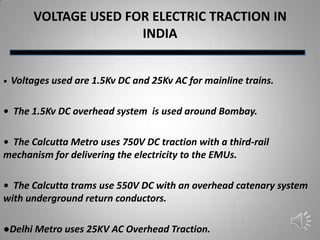

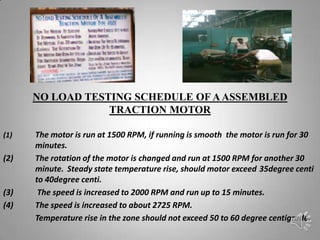

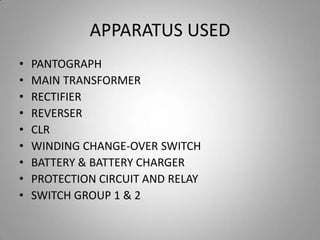

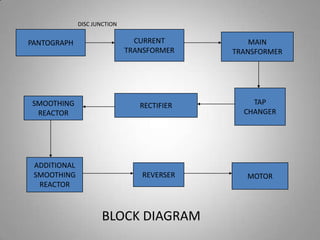

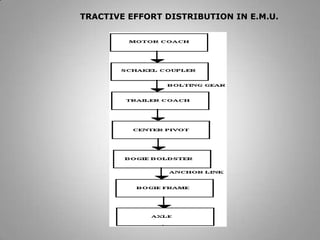

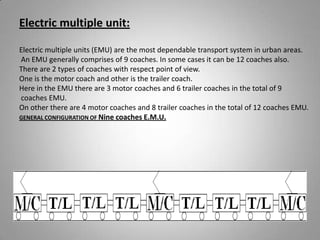

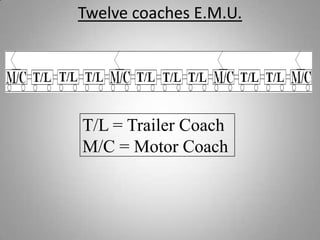

The document provides a report on vocational training received by four students at various Indian Railway locations. It summarizes their visits to Sealdah station power house and substation where they observed feeders, transformers, and the 25kV autotransformer system. It also describes visits to Barasat car shed where they learned about overhead electrification systems, pantographs, and traction motors. Their final visit was to Narkeldanga car shed where they examined equipment like pantographs, transformers, rectifiers, and protection circuits used in electric multiple unit trains.