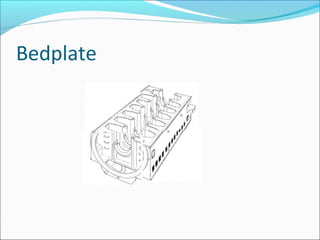

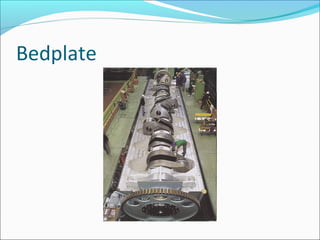

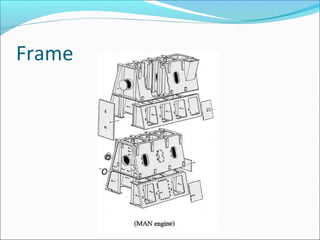

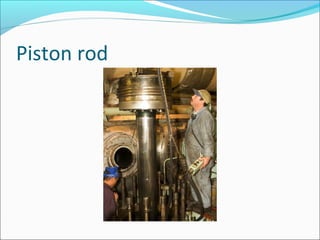

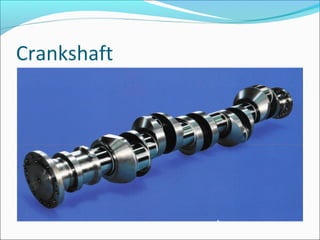

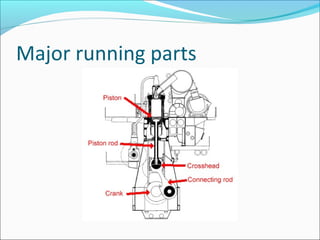

Diesel engines have two main categories of parts: structural parts and running parts. Structural parts like the bedplate, frame, cylinder block, and cylinder head support the running parts and provide passages for cooling, lubrication, and more. Running parts like the piston, connecting rod, and crankshaft convert the combustion energy into rotational motion. Diesel engines also have systems to supply air and fuel, remove exhaust, provide lubrication and cooling, and turbocharge the air. Key specifications include the cylinder bore, stroke, engine speed, and maximum continuous rating.