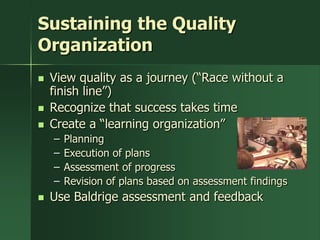

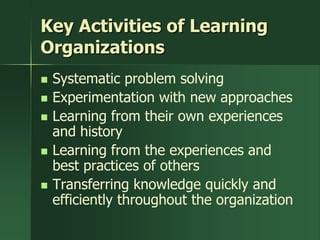

This document provides an overview of key concepts for building and sustaining a total quality organization, including:

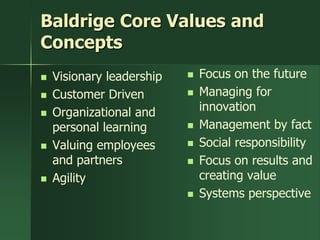

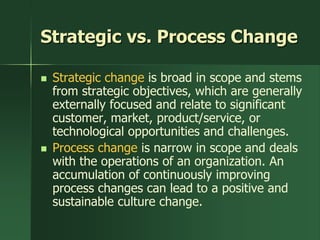

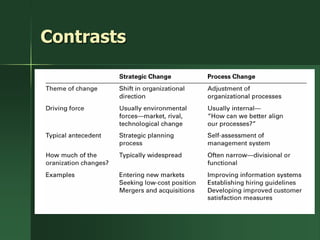

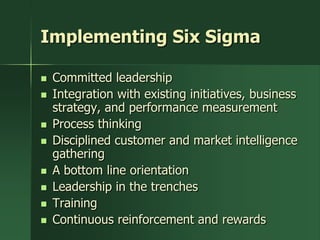

- Adopting sound practices and implementation strategies and having an effective organizational infrastructure are required.

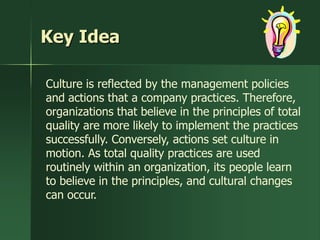

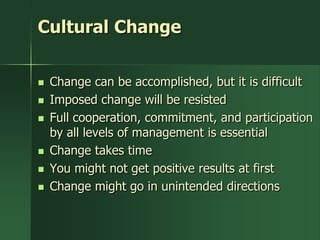

- Cultural changes take time and full participation from all management levels is essential for successful implementation of total quality principles.

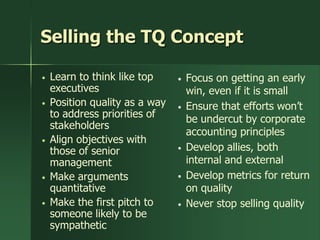

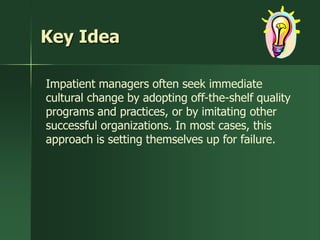

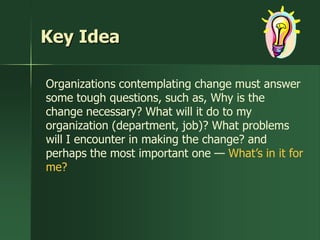

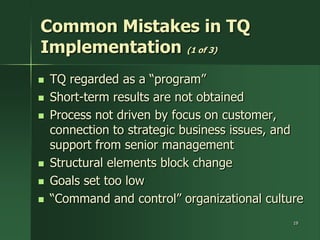

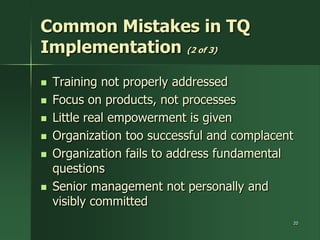

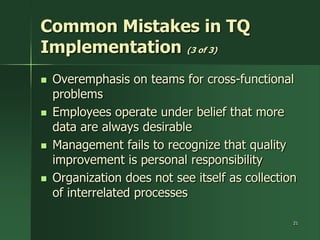

- Common mistakes include not obtaining short-term results, lack of focus on customers and processes, and failure to address fundamental questions.