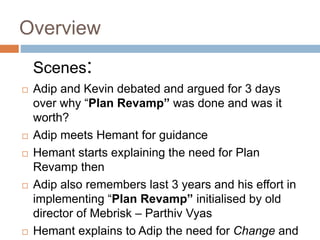

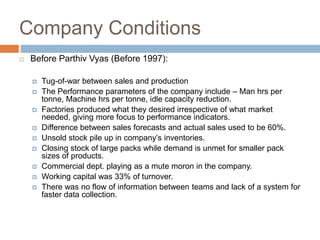

The document summarizes a case study about a company called Mebrisk India that underwent changes to its operations and supply chain management over time. It describes the company's conditions before and after the director Parthiv Vyas implemented a "Plan Revamp" in 1997-1999 to improve coordination between suppliers, production, and sales. The new director Kevin Mathais questions whether the changes were necessary. The case examines whether further changes should be made or if the original revamp should be maintained, and how to best achieve coordination between all parts of the supply chain in a dynamic environment.

![Company Conditions

1997 – 1999 [Changes during Parthiv Vyas]

Zero/negative working capital

JIT inventory at all factory locations and vendor supplied

management

Putting in place an information system to collect and report daily

sales, daily stocks, supplier positions in real-time.

Wiring the entire company (Costly V-Sat connections).

Daily production planning.

Establishment of ZSPs (Zonal Stock Points) and managing ad-

hoc sales requirement.

Disadvantages:

It increased management cost

The IT implementation and wiring was very costly during the time

when it was undertaken.](https://image.slidesharecdn.com/changetobeornottobe-150204030641-conversion-gate01/85/Change-to-be-or-not-to-be-6-320.jpg)

![Company Conditions

2000 and onwards [Kevin Mathais point of view]

The Plan Revamp was indeed very costly and

unnecessary.

With working capital reduction, space should also be

reduced.

No need of stockpiling items at ZSPs. Move it to

stockiests or factories.

Move production planning back to the factory.

Sales should not tell manufacturing, what to produce

and how much to produce.](https://image.slidesharecdn.com/changetobeornottobe-150204030641-conversion-gate01/85/Change-to-be-or-not-to-be-7-320.jpg)

![Facts and Interpretations

The company had spent 17 Crores on the plan revamp

Parthiv vyas came from a company which had commercially driven

environment (Delaware)

Tug-of-War every year between sales and production depts. -

Interpretation Commercial dept needed to be active.

The production and sales plans not in sync

Performance parameters followed in the company in factories : man

hours per tonne, machine hrs per tonne and idle

capacity reduction. - Interpretation - The focus was on man hrs per

tonne in the factory and thus the factory produced what they wanted

irrespective of the market need. [Performance indicators were given

more preference over stocks/inventory Reduction]

Things implemented by Parthiv vyas in Plan Revamp were : Zero or

negative working capital, - JIT inventory management, connect

everyone (factories, depots, regional offices, head office) for the

faster data flow. through VSat connections, Daily Production

Planning.](https://image.slidesharecdn.com/changetobeornottobe-150204030641-conversion-gate01/85/Change-to-be-or-not-to-be-8-320.jpg)