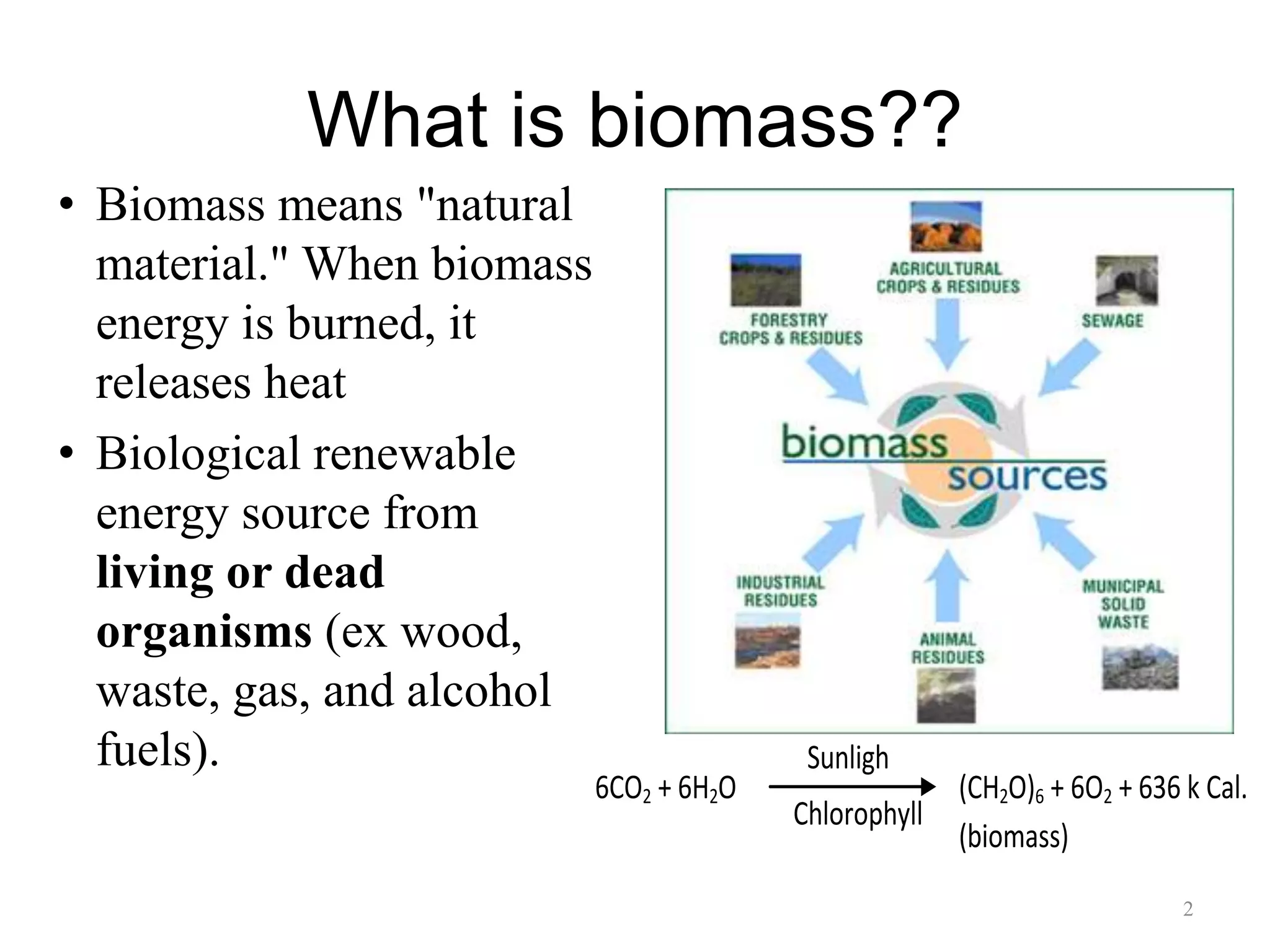

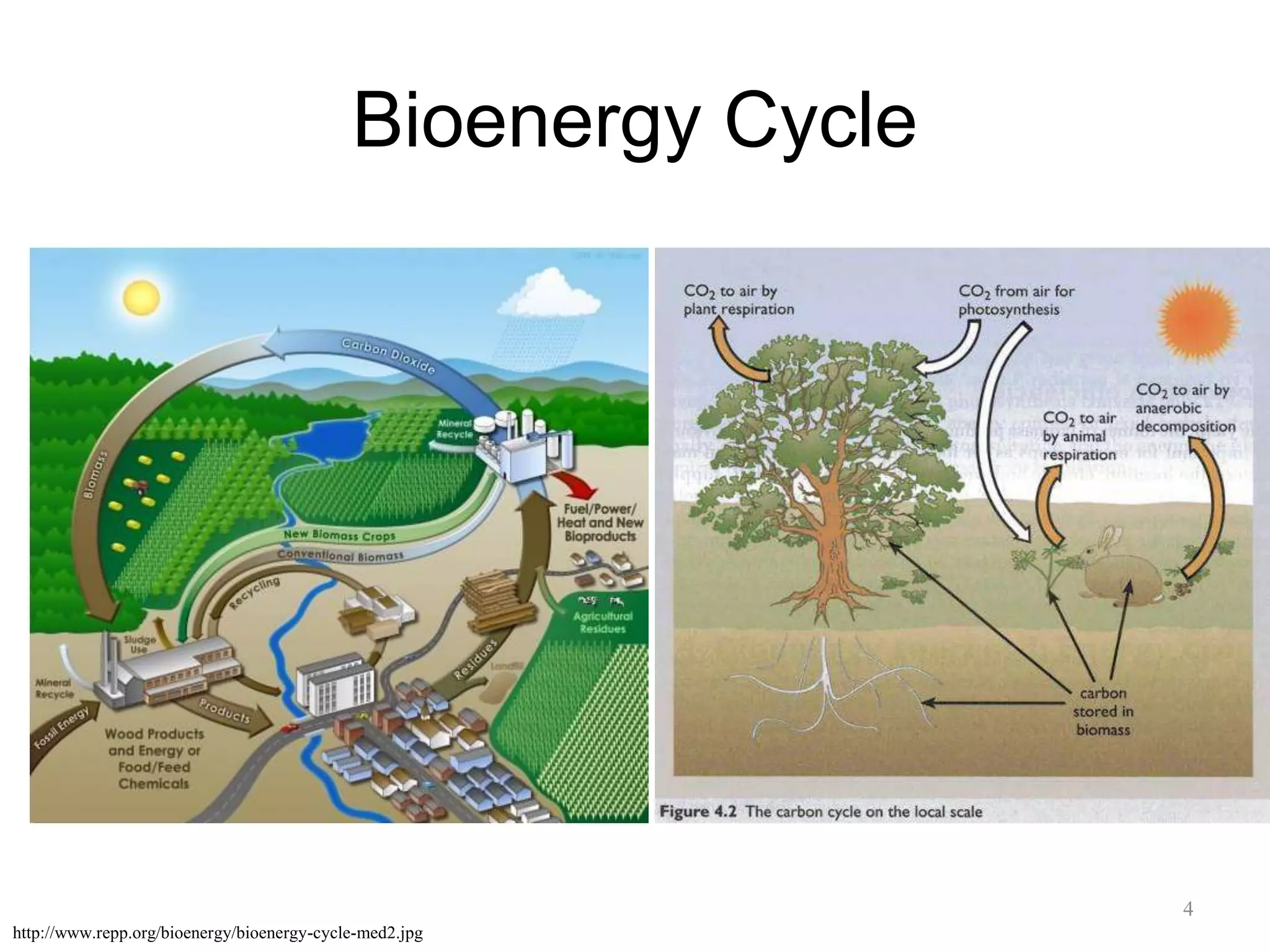

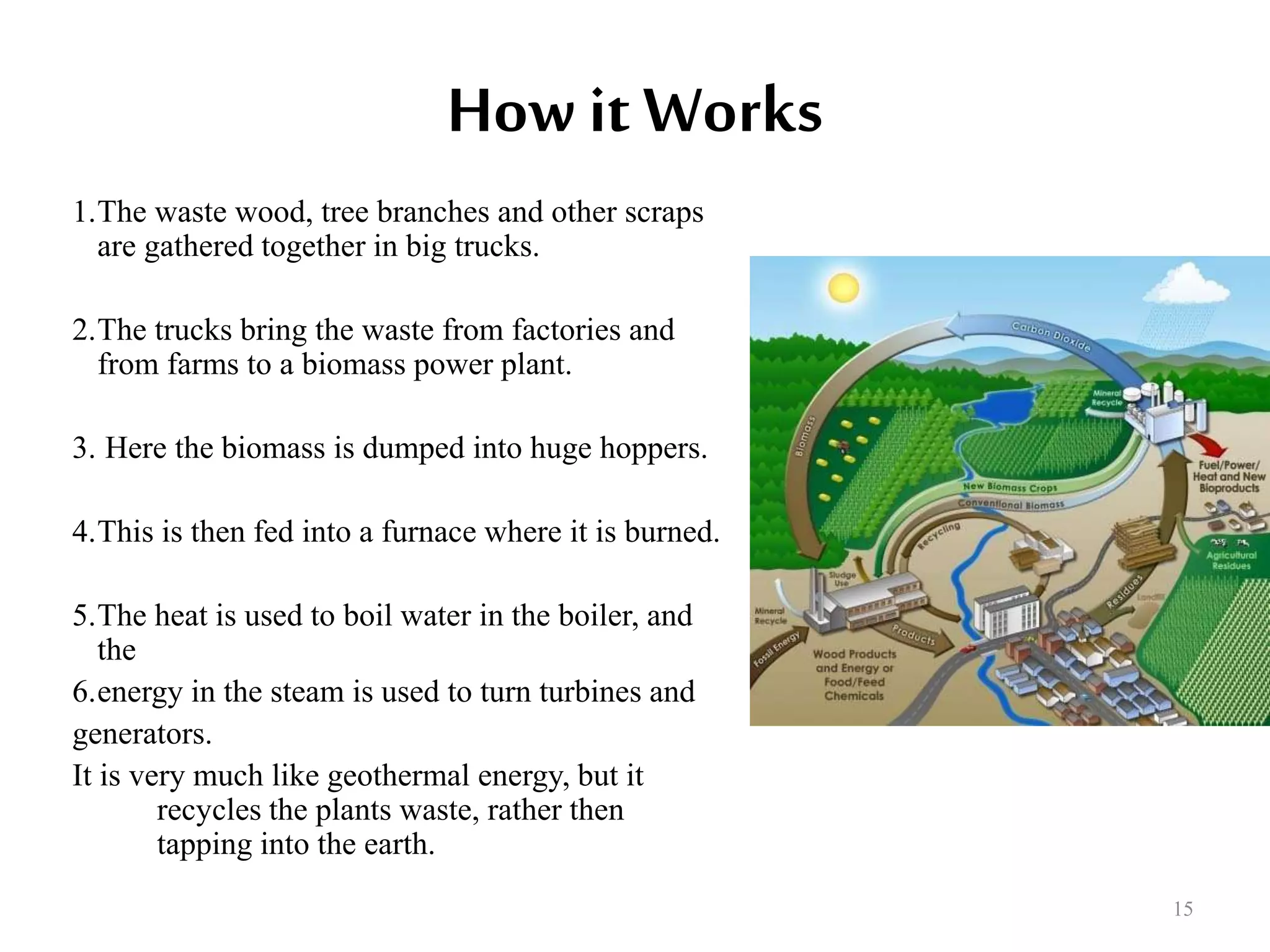

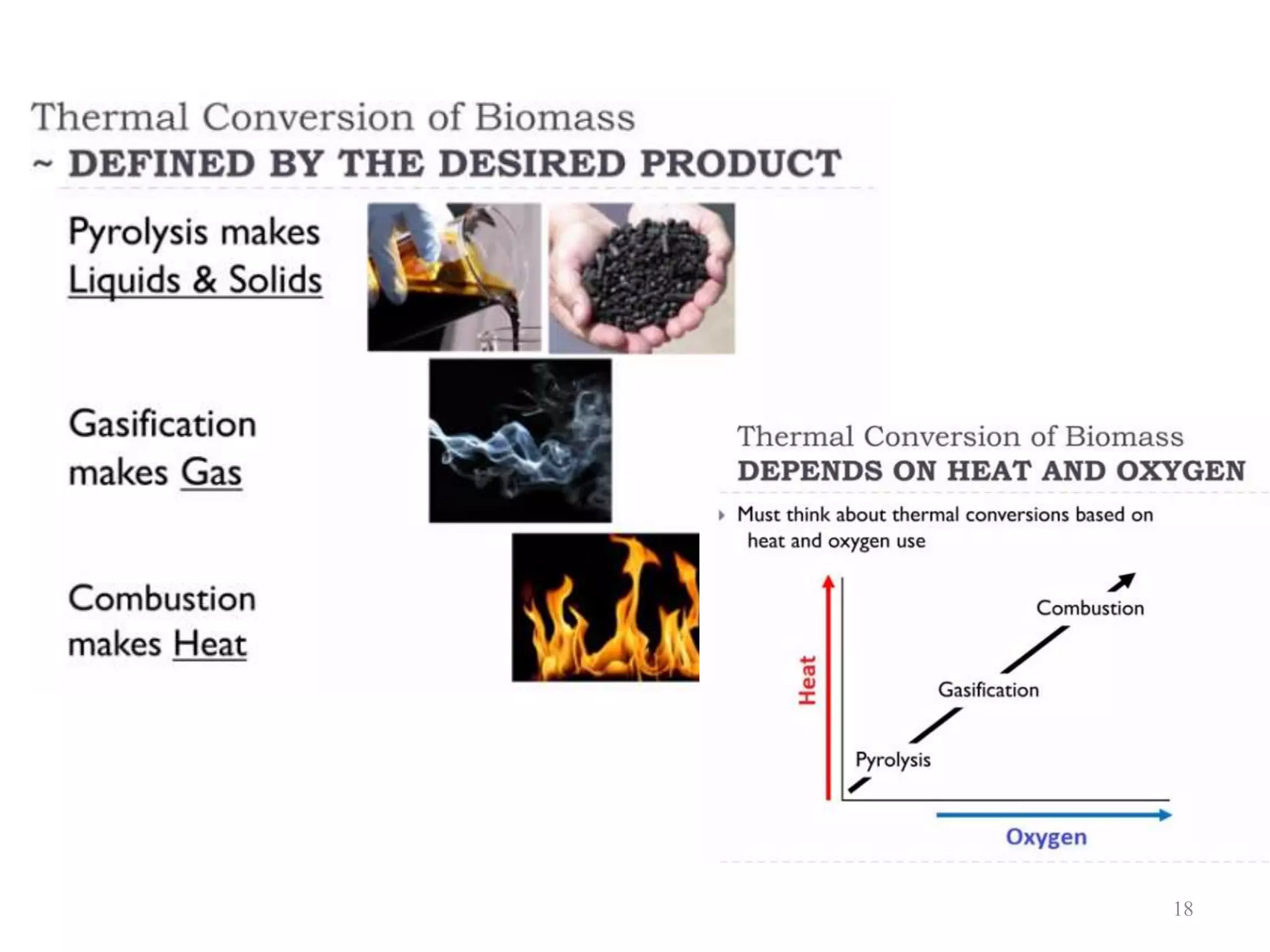

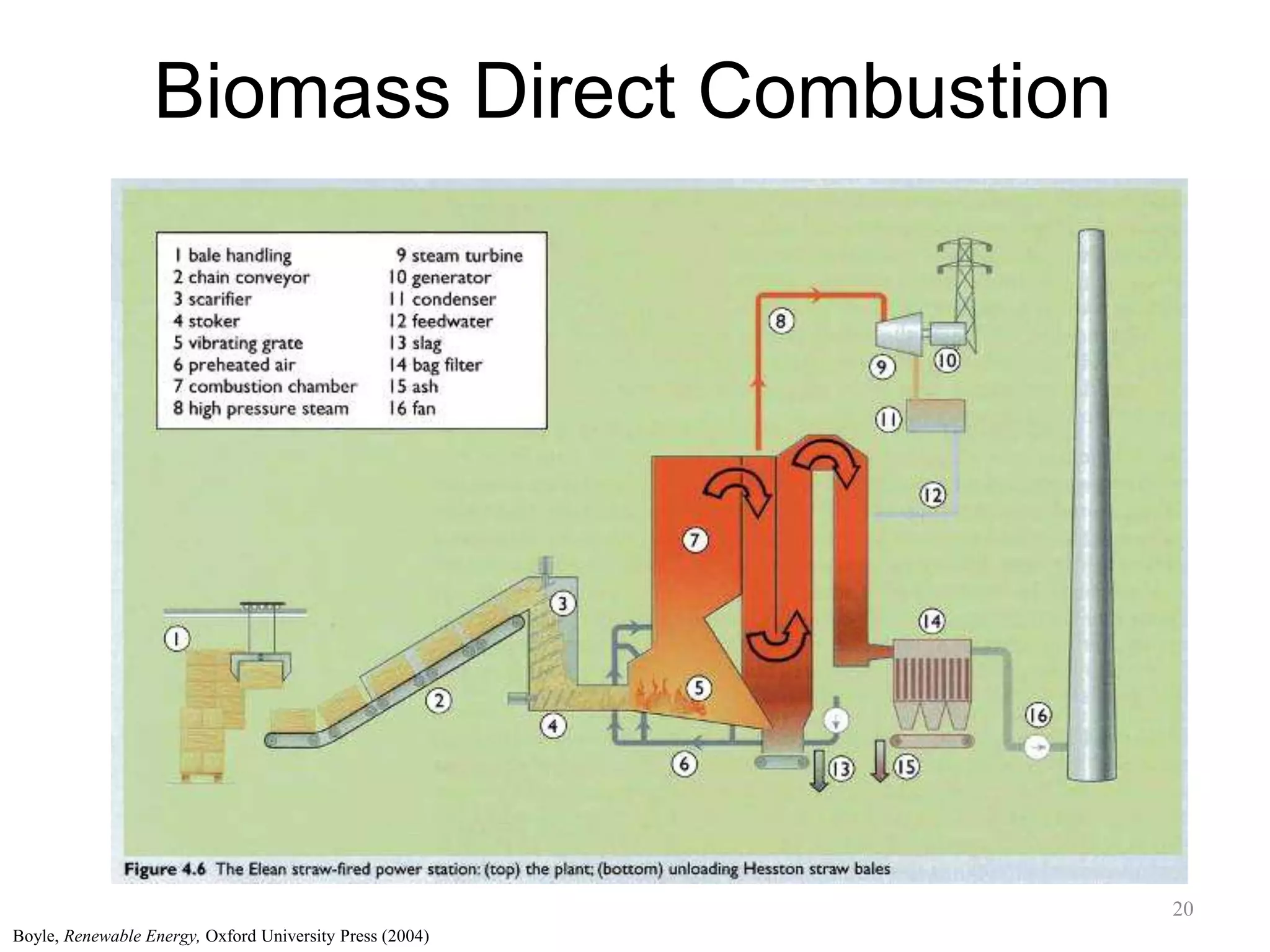

This document discusses biomass as a renewable energy source. It defines biomass as natural material from living or dead organisms that can be converted to energy. Biomass energy is stored in organic compounds that can be converted into heat, gases, solids, liquids or chemicals through combustion, gasification or pyrolysis. Examples of biomass feedstocks include wood, agricultural waste and municipal solid waste. The document also outlines the biomass energy cycle and various biomass conversion technologies and their processes.

![Bioenergy Calculation

32

Composition Percent % kJ/kg Total

Paper 7.73 16,750 1,295

Plastic 18.29 32,500 5,944

Food waste 26.56 4,650 1,235

Wood and yard 8.52 18,600 1,585

*Others 14.92 15,000 2,238

Ferrous 2.47 0 0

Aluminium 0.06 0 0

Glass 1.93 0 0

Sand/fine materials 14.41 0 0

Other inorganics 5.11 0 0

Total 100.00 12,297kJ/kg

kJ --> kWh 0.000278

Throughput: 1800 tons/day

Thermal Power : 256 MW/hour

Electricity Efficiency : 7.5 % 5-10% for a "normal" design

Nomimal power gen : 19.2 MWe/hour [460 MWh/day]](https://image.slidesharecdn.com/biomass-180222053645/75/Biomass-32-2048.jpg)