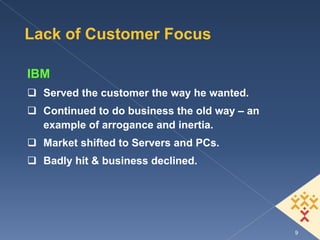

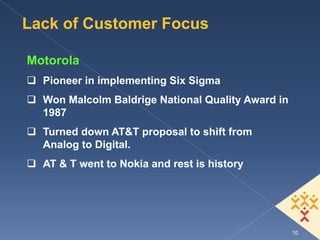

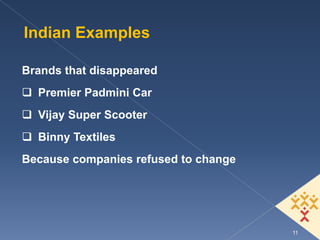

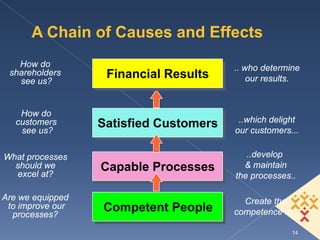

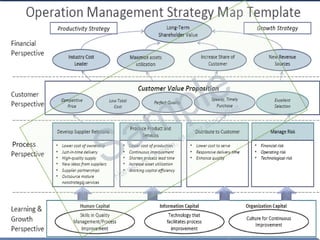

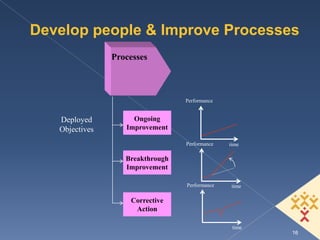

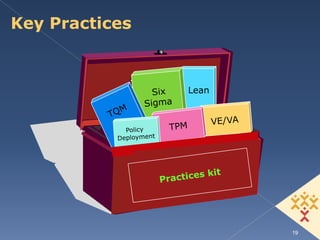

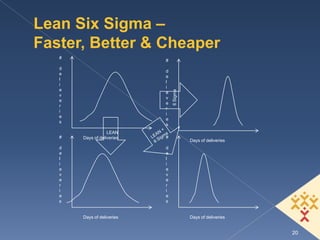

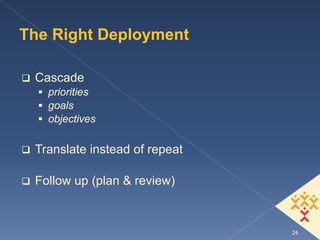

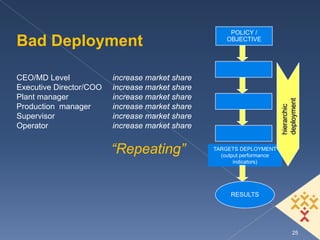

The document outlines key challenges businesses face, emphasizing the importance of customer focus and the consequences of neglecting it, with examples of companies that failed due to arrogance. It discusses strategies for continuous improvement through lean six sigma practices, highlighting three levels of process improvement and the need for effective deployment of organizational goals. Naresh Chawla stresses that effective performance depends on translating strategic intent into actionable objectives and maintaining customer satisfaction.